Precursor polymer for manufacturing fine ceramic components and synthesis method thereof

A technology of fine ceramics and precursors, which is applied in the field of precursor polymers and their synthesis, can solve the problems of precursor adhesion, poor high temperature resistance, and easy deformation, etc., and achieve the goals of improved precision, improved optical activity, and improved curing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: 1, the reaction of 1-diacrylate methylenyl isocyanate and polysilazane

[0030] Follow the standard Schlenk technique on the vacuum line as follows:

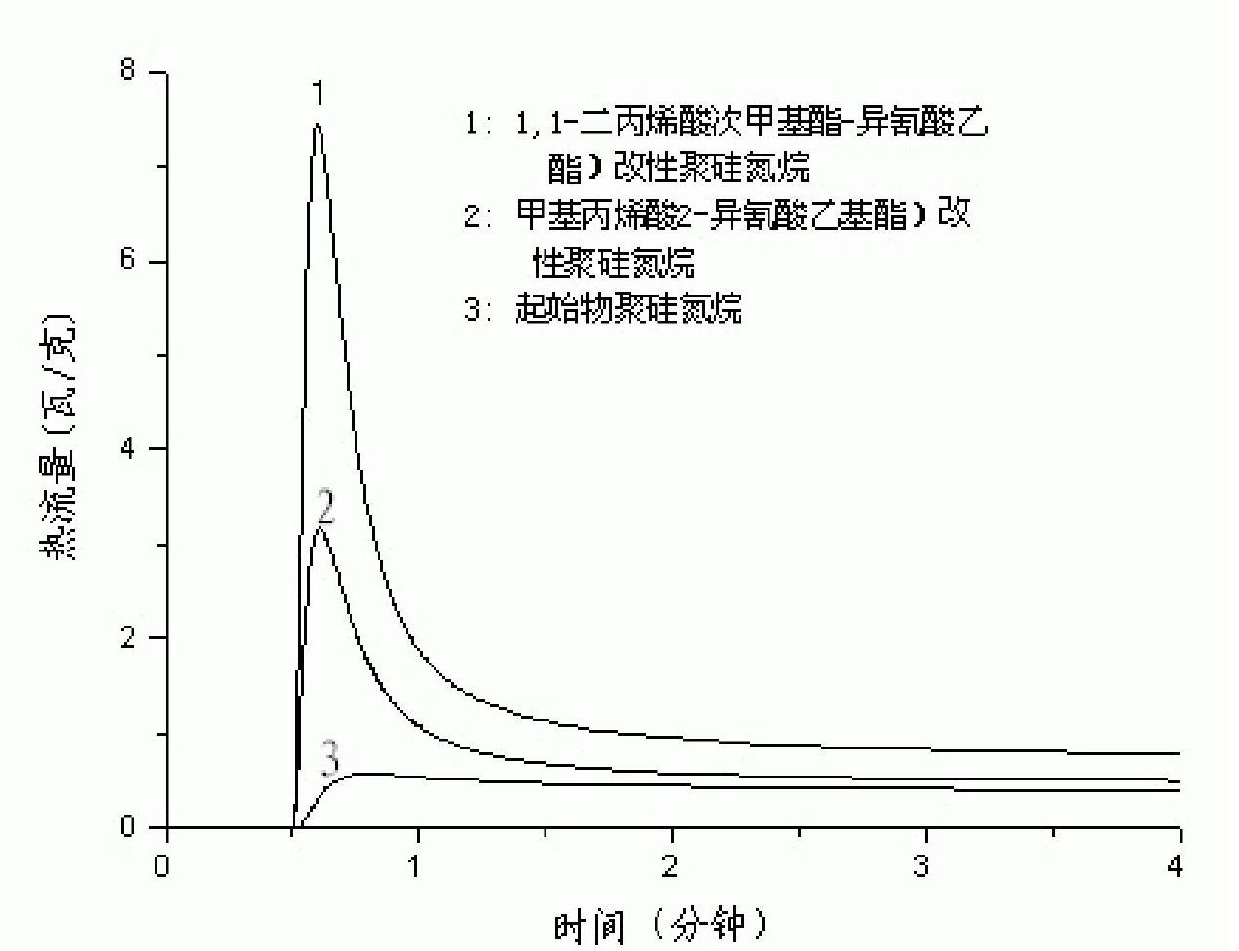

[0031] In a typical chemical reaction, 5.0 g of silazane oligomers are dissolved in 15 ml of tetrahydrofuran solvent, stirred with a medium-speed magnetic force for 10 to 20 minutes to make them evenly mixed, and then 1 g of (1,1-diacrylic acid Methylene ester ethyl isocyanate), keep continuous magnetic stirring, react at room temperature (25°C) for about 60-80hrs, stop the reaction after the color of the reaction mixture changes from colorless to light yellow. After the reaction, the tetrahydrofuran solvent and a small amount of residual BEI in the product were removed by a high vacuum pump. The product was marked as PVSZ-BEI, and the product yield was 88.6%. from figure 1 It can be seen from the curve 2 that the peak heat flow of PVSZ-BEI is 7.9w / g, and there is no tailing phenomenon; the peak heat flow ...

Embodiment 2

[0032] Embodiment 2: the reaction of 2-isocyanate ethyl methacrylate and polysilazane

[0033] In a typical chemical reaction, 4.0g of polysilazane is dissolved in 15ml of tetrahydrofuran solvent, stirred with a medium-speed magnetic force for 10-20min to make it evenly mixed, and then slowly add 1g of IEM (methacrylic acid 2-isocyanic acid Ethyl ester), after the dropwise addition, the temperature was raised slowly, and finally the reaction was carried out at a constant temperature of 50° C. for 15-28 hours, and continuous medium-speed magnetic stirring was maintained during the reaction. After the reaction, the precipitate was removed by centrifugation and filtration to obtain a colorless and transparent low-viscosity liquid, and then the tetrahydrofuran solvent and residual IEM in the product were removed by a high vacuum pump. The product was marked as PVSZ-IEM, and the product yield was 82.8% %. The chemical reaction device is similar to that described in Example 1, requ...

Embodiment 3

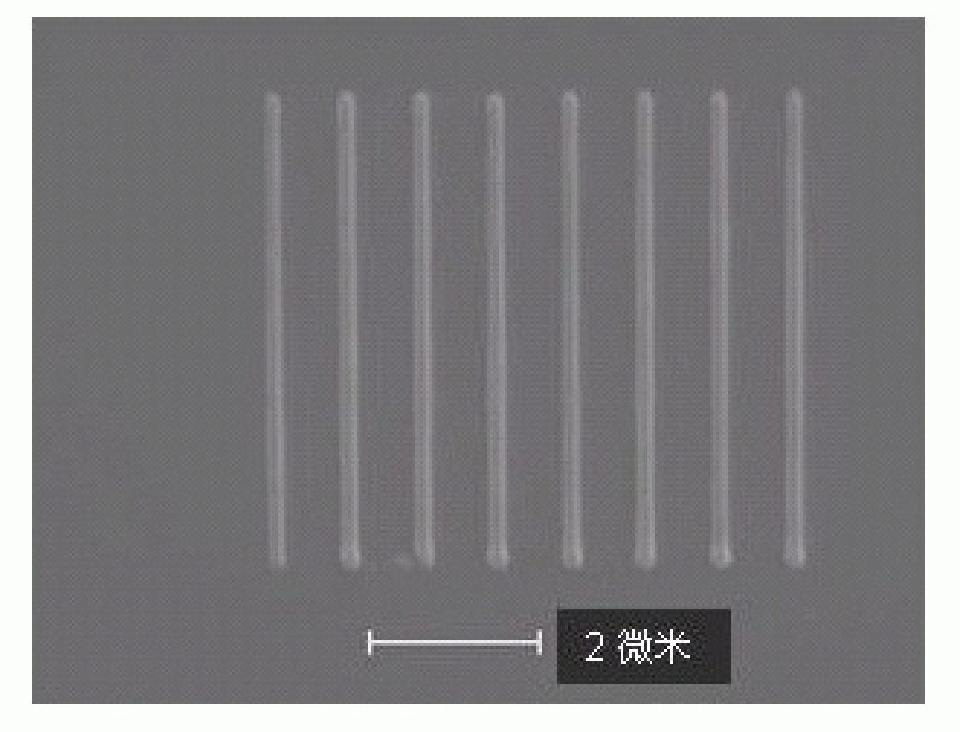

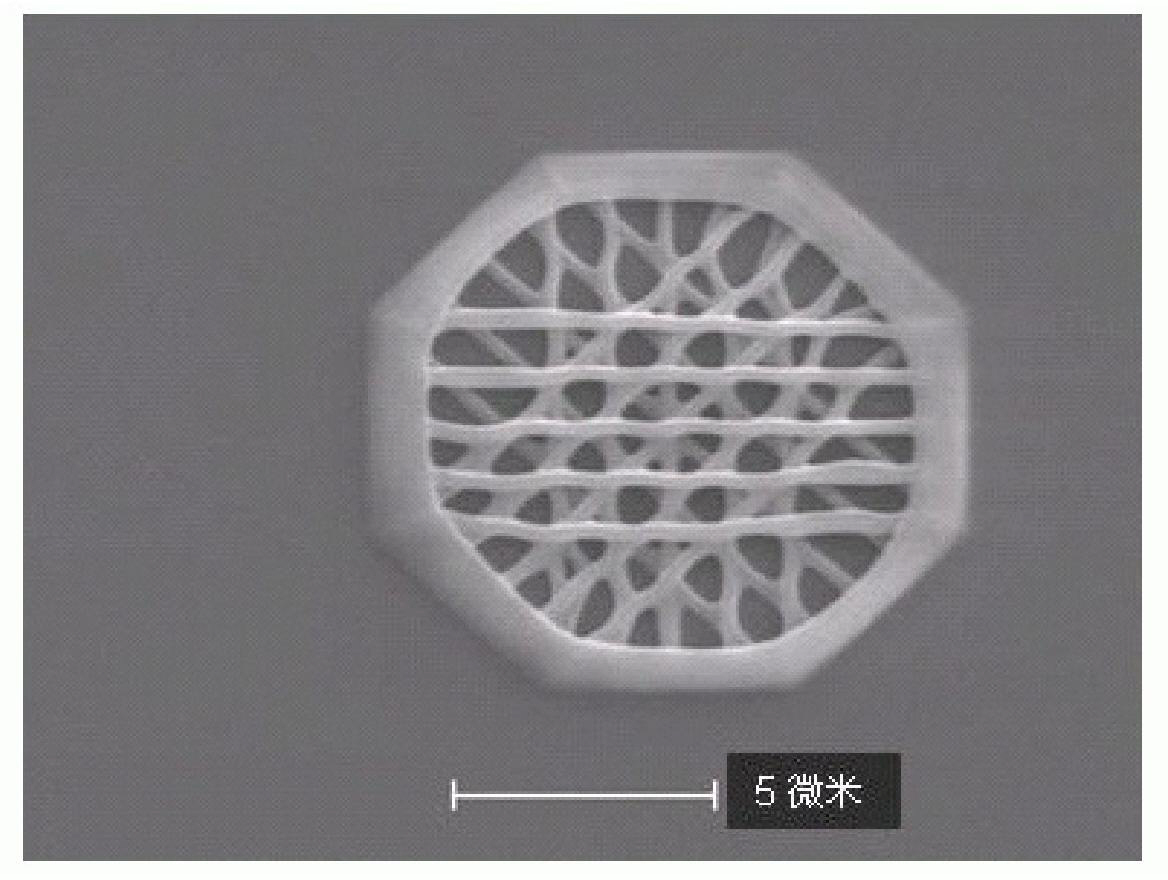

[0034] Example 3: Fabrication of microfluidic ceramic components using two-photon absorption three-dimensional etching technology

[0035] Add 1.0~3.0mg of laser dye to 0.5ml of toluene, oscillate fully to dissolve it completely, then add 0.5~1.0g photocurable modified polysilazane PVSZ-BEI, oscillate fully to mix evenly, and then The solvent was removed by vacuum on the line. The criteria for a qualified sample are: the initiator is completely dissolved, the solvent toluene is completely removed, and when observed under a microscope, the sample is uniform and transparent without the appearance of granular substances. Take 1 drop of the sample and put it on a glass slide for two-photon absorption three-dimensional etching. The two-photon absorption three-dimensional etching system used in the present invention consists of three parts: laser source, optical path control, and three-dimensional etching. The laser light source is provided by a Ti: Sapphire femtosecond laser (Ti:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com