pH-responsive amphiphilic grafted polyphosphazene and its synthesis method

A synthesis method and technology of polyphosphazene, which is applied in the field of pH-responsive amphiphilic grafted polyphosphazene and its synthesis, can solve the problems of harsh conditions and medical application restrictions, and achieve low toxicity, strong pH response characteristics, biophase good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) Prepare poly(dichlorophosphazene) with aluminum chloride as catalyst

[0060] Weigh 4 g of chlorophosphazene cyclic trimer purified by sublimation and 0.2 g of anhydrous aluminum trichloride into a pre-cleaned and dried polymerization tube, vacuumize and seal the tube, carry out the polymerization reaction at 250°C for 5 hours, and wait for When the viscosity of the reactant remained almost constant, the polymerization was stopped and the polymerization tube was taken out to cool. Unseal the polymerization tube, add an appropriate amount of dry toluene solution to dissolve the reactants. After dissolution, it was precipitated with petroleum ether and dried in vacuum to obtain a white elastomer, that is, poly(dichlorophosphazene).

[0061] (2) Synthesis of pH-responsive amphiphilic grafted polyphosphazene copolymers via stepwise nucleophilic substitution reactions

[0062] Dissolve 0.5 g of the above-prepared linear poly(dichlorophosphazene) in 20 ml of THF as a re...

Embodiment 2

[0068] (1) The preparation of poly(dichlorophosphazene) is the same as in Example 1.

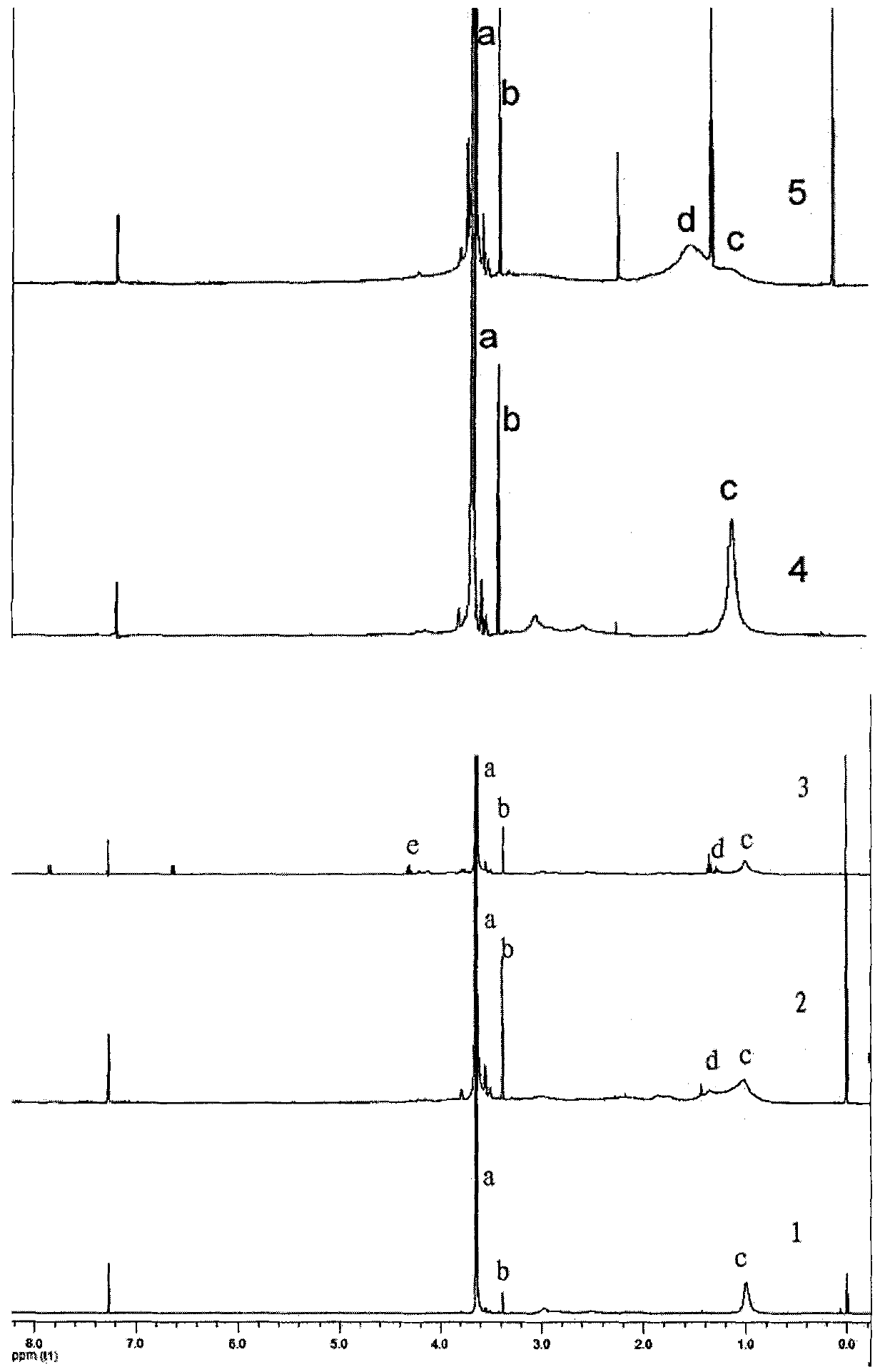

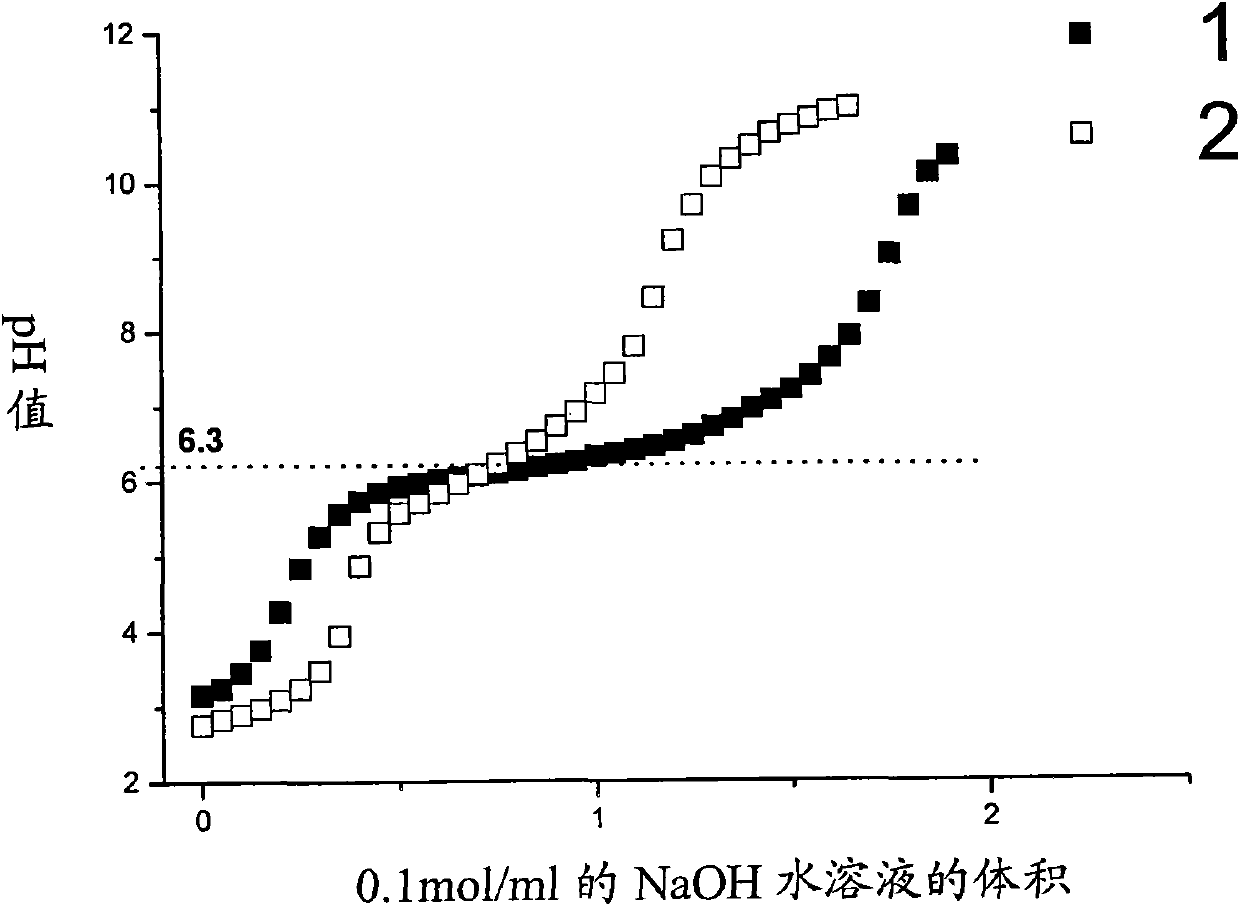

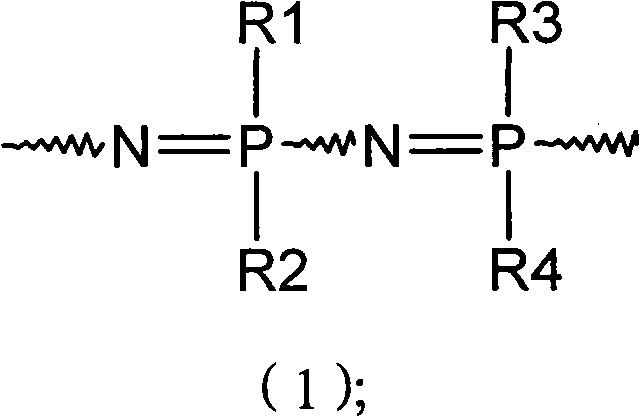

[0069] (2) In addition to slowly adding 2.2g NH 2 - 50ml of THF solution of PEG (its molecular weight is 2000) and 0.2ml TEA, 10ml of THF solution containing 0.5g N,N-diisopropylethylenediamine (DPA) and 0.5ml TEA and 0.7g p-aminobenzoic acid Except 10 milliliters of the THF solution of ethyl ester (EAB) and 0.5ml TEA, all the other operations are all the same as the step (2) in the embodiment 1, obtain the pH response type amphiphilic graft polyphosphazene copolymer, in this copolymer The mass percentage of the water-terminal amino polyethylene glycol is 60%, the mass percentage of N-[2-(N', N'-diisopropylamino) ethyl]amino is 15%, and the N-( The mass percent content of ethyl benzoate)-4-amino is 20%, its number average molecular weight is 5000, molecular weight distribution is 2.8, and pKa value is 6.34. The NMR spectrum of the copolymer is figure 1 As shown, its structural formula is ...

Embodiment 3

[0074] (1) The preparation of poly(dichlorophosphazene) is the same as in Example 1.

[0075] (2) In addition to slowly adding 6g NH 2 50ml of THF solution of PEG (its molecular weight is 2000) and 0.6ml TEA, 10ml of THF solution containing 0.8g N,N-diisopropylethylenediamine (DPA) and 0.8ml TEA, 0.8g p-aminobenzoic acid Ethyl ester (EAB) and 0.7ml TEA THF solution 10ml and 2.0g serine ethyl ester (SEE) and 1.5ml TEA THF solution 10ml, and each time a class of raw materials was added dropwise and reacted at room temperature for 8h, the rest The operation is the same as the step (2) in Example 1 to obtain a pH-responsive amphiphilic grafted polyphosphazene copolymer. The mass percentage of the amino-terminated polyethylene glycol of the hydrophilic segment in the copolymer is 70%, and the N -[2-(N', N'-diisopropylamino) ethyl] amino is 10% by mass, and N-(benzoic acid ethyl)-4-amino is 6% by mass , N-[beta-hydroxypropionate ethyl] amino mass percent content is 4%, its number ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com