Preparation method and application of a pH-responsive calcium alginate/vaterite calcium carbonate composite microsphere with controllable release rate

A technology of release rate and composite microspheres, which is applied in the direction of medical preparations of non-active ingredients, pharmaceutical formulas, inorganic non-active ingredients, etc., can solve the problems of poor mechanical strength, weak drug loading capacity, water absorption and easy breakage, etc., and achieve the goal of overcoming Unstable crystal form, reducing the effect of initial burst release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

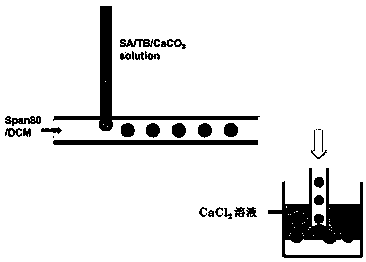

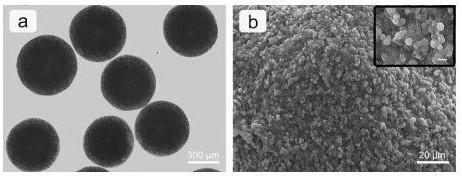

[0038] A pH-responsive calcium alginate / vaterite calcium carbonate composite microsphere with controllable release rate is prepared by the following method:

[0039] (1) Co-precipitation method to prepare vaterite calcium carbonate suspension: add Na at a concentration of 50mM to a beaker with a capacity of 100mL 2 CO 3+8mg / mL casein 20mL, 600rpm magnetic stirring, magnet diameter 40mm, at the same time add 20mL50mM CaCl in the separatory funnel 2 , Open the cock just above the beaker and add evenly. Stir magnetically for 20 minutes. After the stirring is completed, the carbonate ions and calcium ions in the solution react completely at this time to obtain CaCO 3 Suspension, i.e. vaterite calcium carbonate suspension, in which CaCO 3 The concentration is 2.5mg / mL.

[0040] (2) Prepare a sodium alginate (SA) solution with a mass concentration of 2%: weigh the SA powder, add water and stir to prepare an SA solution with a mass concentration of 2%.

[0041] (3) Prepare the i...

Embodiment 2

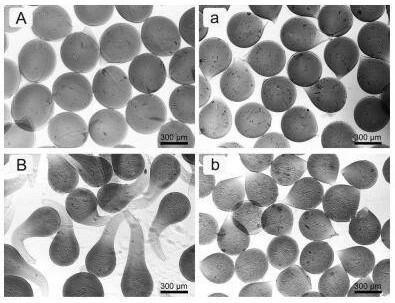

[0046] The effect of the type of external phase and the flow rate on the composite microspheres was investigated.

[0047] The external phase is set to dichloromethane, dichloromethane+surfactant, ethyl acetate+surfactant, wherein there are many choices of surfactants, taking the commonly used Span80 as an example, the mass ratio of its addition is 3% of the external phase %. The flow rates of the external phase were set to 50 μL / min, 200 μL / min, 400 μL / min, and 800 μL / min, respectively.

[0048] (1) Taking single calcium alginate as a comparative example, according to the above-mentioned different types of external phases and flow rates, the influence of the type of external phase on single calcium alginate microspheres was investigated.

[0049] The result is as image 3 As shown, the external phase of Figure A is dichloromethane, and the single calcium alginate microspheres and composite microspheres are elliptical; the external phase of Figure a is dichloromethane+3% Spa...

Embodiment 3

[0052] The effect of the added amount of vaterite calcium carbonate on the shape and particle size of composite microspheres was investigated.

[0053] When preparing composite microspheres according to the method in Example 1, during the preparation of the internal phase, the volumes of the vaterite calcium carbonate suspension drawn were respectively 2 mL, 8 mL and 16 mL, i.e. the vaterite in the internal phase The quality of calcium carbonate is 5mg, 20mg and 40mg respectively, according to the quality of vaterite calcium carbonate, it is divided into A-5 group, A-20 group and A-40 group respectively. Observe the shape and particle size of the composite microspheres prepared by A-5 group, A-20 group and A-40 group, the results are as follows: Figure 5 shown. Figures a, b and c correspond to group A-5, group A-20 and group A-40, respectively. The results show that after adding different amounts of vaterite calcium carbonate, the prepared composite microspheres have no cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com