Thermal deposition surface treatment method, system and product

一种热沉积、热处理装置的技术,应用在热处理炉、热处理设备、炉等方向,能够解决窄误差容限、控制温度即热堆积和工件内热均匀性困难等问题,达到过程波动可靠的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

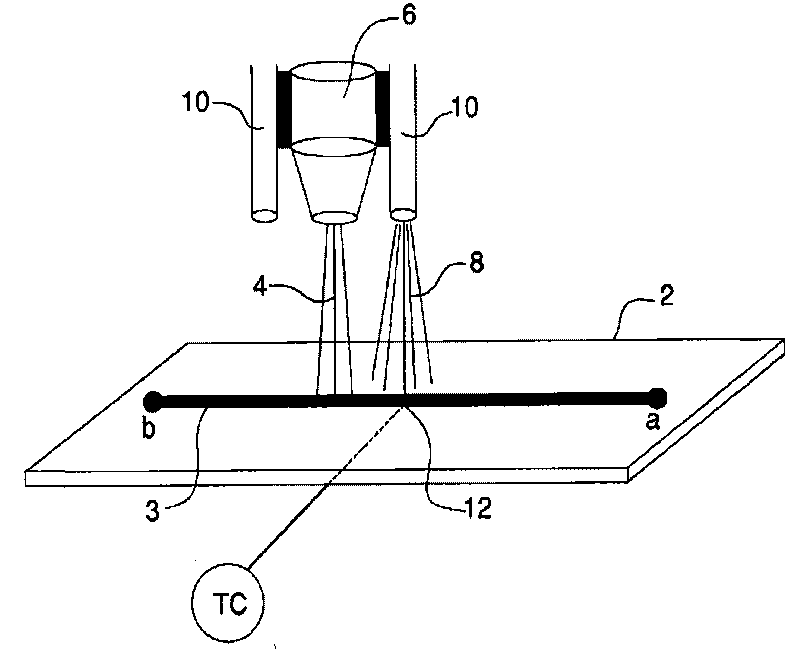

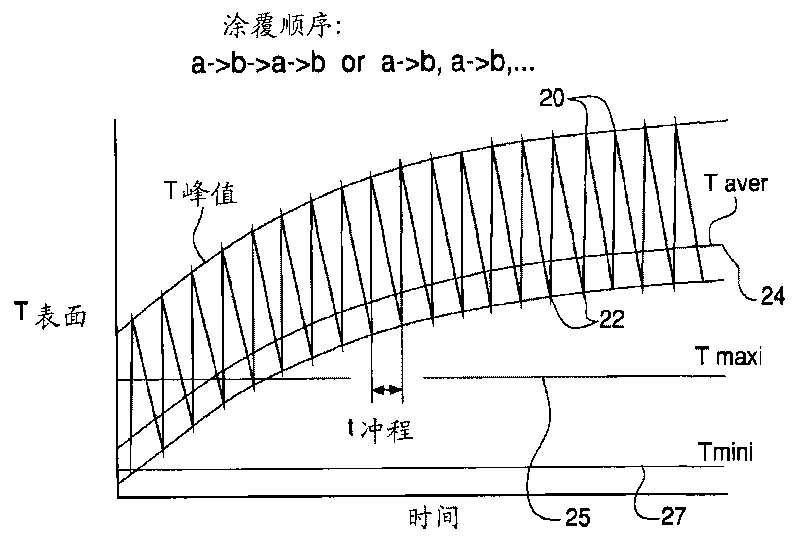

[0065] The purpose of this example is to more fully explain the Figure 6 Control parameters enumerated in the description of the process steps shown. Figure 4 , 5 and 6 are used to make the description easy.

[0066] Figure 4 A thermal deposition method is illustrated using a workpiece 40 comprising a workpiece base surface 41 having a cylindrical shape and being rotated during the thermal deposition coating method. A workpiece (RW) comprising a workpiece substrate surface 41 is mounted in a remotely actuated rotating carriage (RWA) 42 and exposed to thermal coating deposition material 46 from a thermal deposition head (TCD) 44, thermally deposited The head (TCD) 44 is in turn traversed across the workpiece surface by a separate brake mount (TCDA) arrangement. Simultaneously moving laterally with the thermal deposition head 44 is an elongated cryogenic coolant distributor (SCMD) 48 which provides a cooling effect on only the coated portion of the substrate 41 or on unco...

Embodiment 2

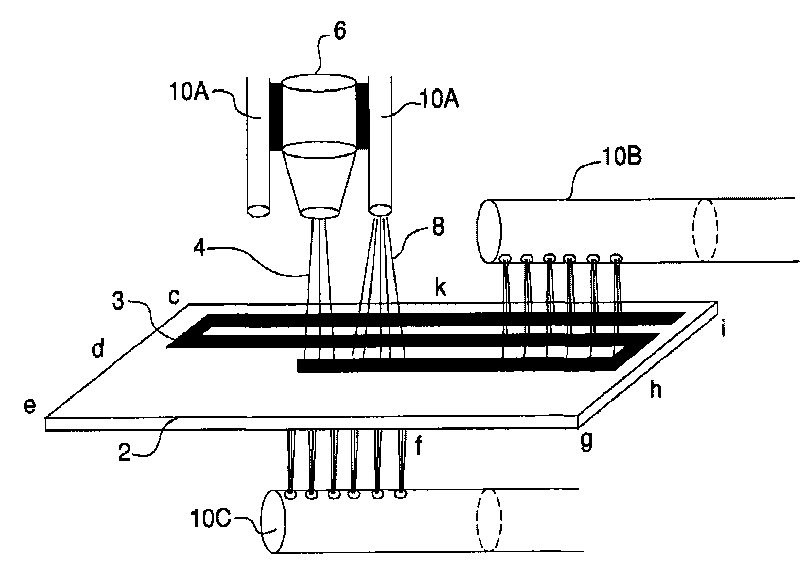

[0073] image 3 A diagram of a thermal deposition process for workpieces optionally using laterally moving and stationary cryogenic coolant delivery systems. and figure 1 Those common equipment components shown are numbered similarly. In illustrating a method of establishing cooling in a thermal deposition coating operation using a cryogenic gaseous coolant medium, coolant 8 is provided by one or more coolant devices 10A, 10A', 10B, and 10C. These coolant devices such as 10A, 10A' can move with the thermal deposition head 4, Figure 4 The dispenser 48 shown in the figure moves as it moves, or remains stationary. Due to the resulting stress distribution, it is more necessary to cool the top side of the workpiece, which is the surface of the workpiece to be coated, where heat is deposited together with the coating material, than the rear side of the workpiece. Of course, cooling the top side of the workpiece surface is more difficult, whether or not the cooled portion o...

Embodiment 3

[0076]Industrial trials of the present system and method were conducted during HVOF spray coating operations involving WC-Co coating materials. The HVOF gun sprays 45 grams of WC-Co powder per minute on a long and narrow rotating aircraft landing gear component made of high-strength steel. The surface speed of the rotating part was 150 ft / min, the gun traverse speed was 1 / 8 inch per revolution, and the distance between the gun nozzle and the part surface was about 9 inches. The HVOF flame is hydrogen-oxygen with a hydrogen flow rate of 1525 scf / hr at 150 psig supply pressure and an oxygen flow rate of 475 scf / hr at 165 psig supply pressure. Four cryogenic fluid nozzles were positioned approximately evenly along the axis of the rotating member at a distance of about 4 inches from the surface of the rotating member. The nozzles discharge a 2-phase mixture of cryogenic nitrogen vapor and a spray of mist-sized liquid droplets to the surface for cooling. The cryogenic fluid suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com