Comprehensive resource recycling method for waste diamond tool

A diamond tool and recycling technology, applied in the direction of solid waste removal, etc., can solve the problems of low recycling efficiency and large waste of waste diamond tools, and achieve the effect of easy industrial scale production, simple process, and smooth and complete surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

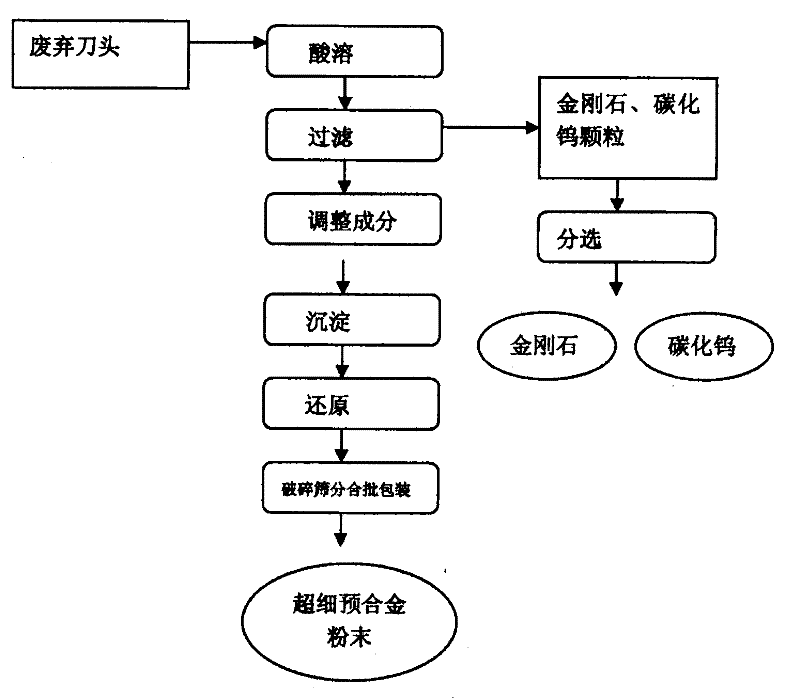

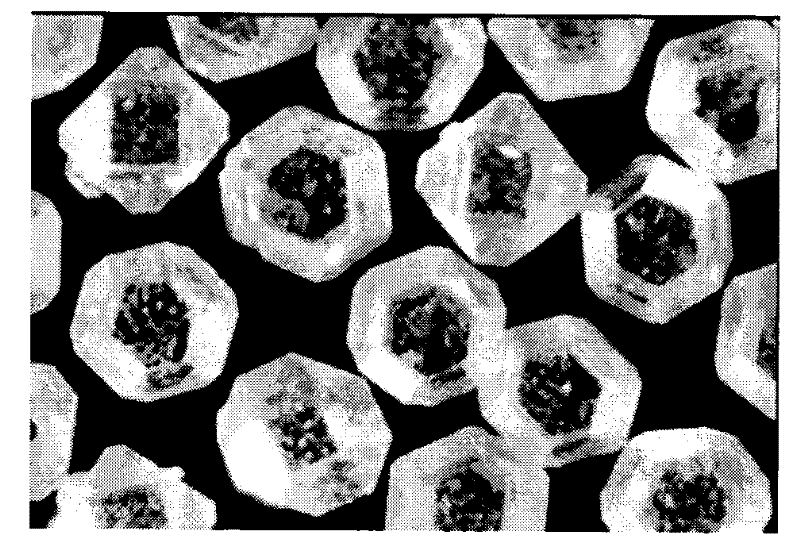

[0029] figure 1 The technical roadmap adopted for the present invention; figure 2 It is the microscopic morphology of diamond particles recovered in the present invention. First prepare the mixed acid solution according to the volume concentration of concentrated sulfuric acid, concentrated hydrochloric acid and concentrated nitric acid being 0, 80% and 20% respectively; take 15kg of the mixed acid solution and slowly add it to the enamel reaction kettle with the same volume of deionized water as the mixed acid , take 1 kg of discarded diamond tools and slowly add them to the above reactor, heat the reactor to 40°C, keep the stirring speed at 50r / min, and bubbles will continue to emerge during the reaction process; after the discarded diamond tools are completely dissolved, put the The solid-liquid mixture is moved to a ceramic filter for filtration, and the undissolved solid particles are separated, and the solid particles are washed repeatedly with deionized water until th...

Embodiment 2

[0031] Firstly, the mixed acid solution is prepared according to the volume concentrations of concentrated sulfuric acid, concentrated hydrochloric acid and concentrated nitric acid being 30%, 40% and 30% respectively. Take 8kg of mixed acid solution and slowly add it to the enamel reaction kettle with the same volume of deionized water as the mixed acid, take 1kg of waste diamond tools and slowly add it to the above reaction kettle, heat the reaction kettle to 80°C, and stir at a speed of 200r / min , During the reaction process, there are constantly bubbles coming out. After the waste diamond tools are completely dissolved, move the solid-liquid mixture in the reactor to a ceramic filter to filter, separate the undissolved solid particles, and repeatedly wash the solid particles with deionized water. Wash until the pH value of the washing filtrate is 7. The washed solid particles were dried in an electric drying oven at a drying temperature of 150° C. and a drying time of 2 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com