Micro powder dry-type magnetic separator

A magnetic separator and dry technology, applied in the field of micropowder dry magnetic separator, can solve the problems of ineffective separation, coarse separation, low separation efficiency, etc., achieve good iron removal effect, and solve separation problems. Difficult, large surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

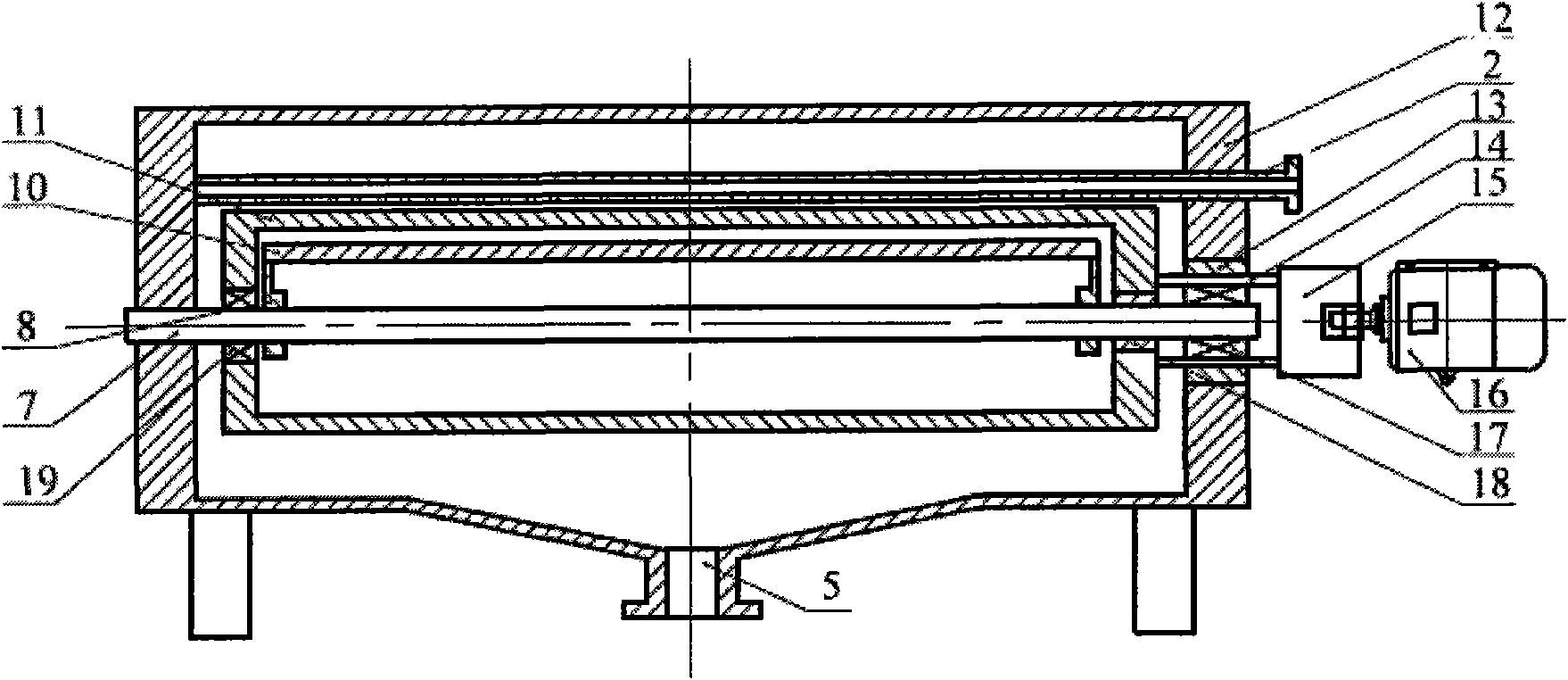

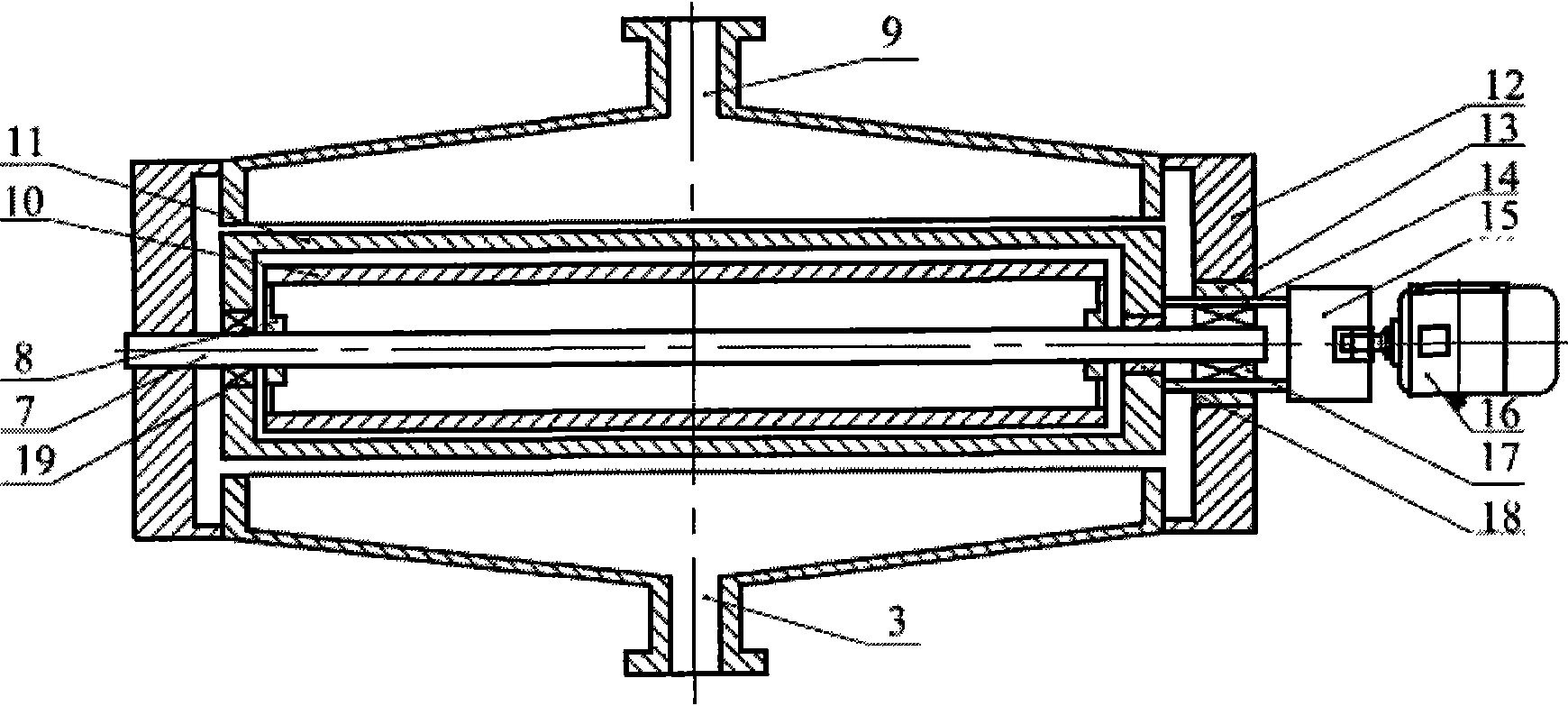

[0021] A kind of micropowder dry type magnetic separator, its structure is as follows figure 2 and image 3 As shown: the two ends of the magnetic drum 11 are respectively concentrically installed on the fixed shaft 7 through the left end bearing 19 and the right end shaft bushing 18, the left end of the fixed shaft 7 is fixed on the left side of the sealed casing 12, and the fixed shaft 7 The right end passes through the shaft bushing 18 and is horizontally installed in the right end bearing 17 in the hollow shaft 14; the right side of the magnetic drum 11 is connected with the hollow shaft 14, the motor 16 is connected with the hollow shaft 14 through the reducer 15, and the hollow shaft 14 passes through The bearing bush 13 is installed on the right side of the sealed casing 12 .

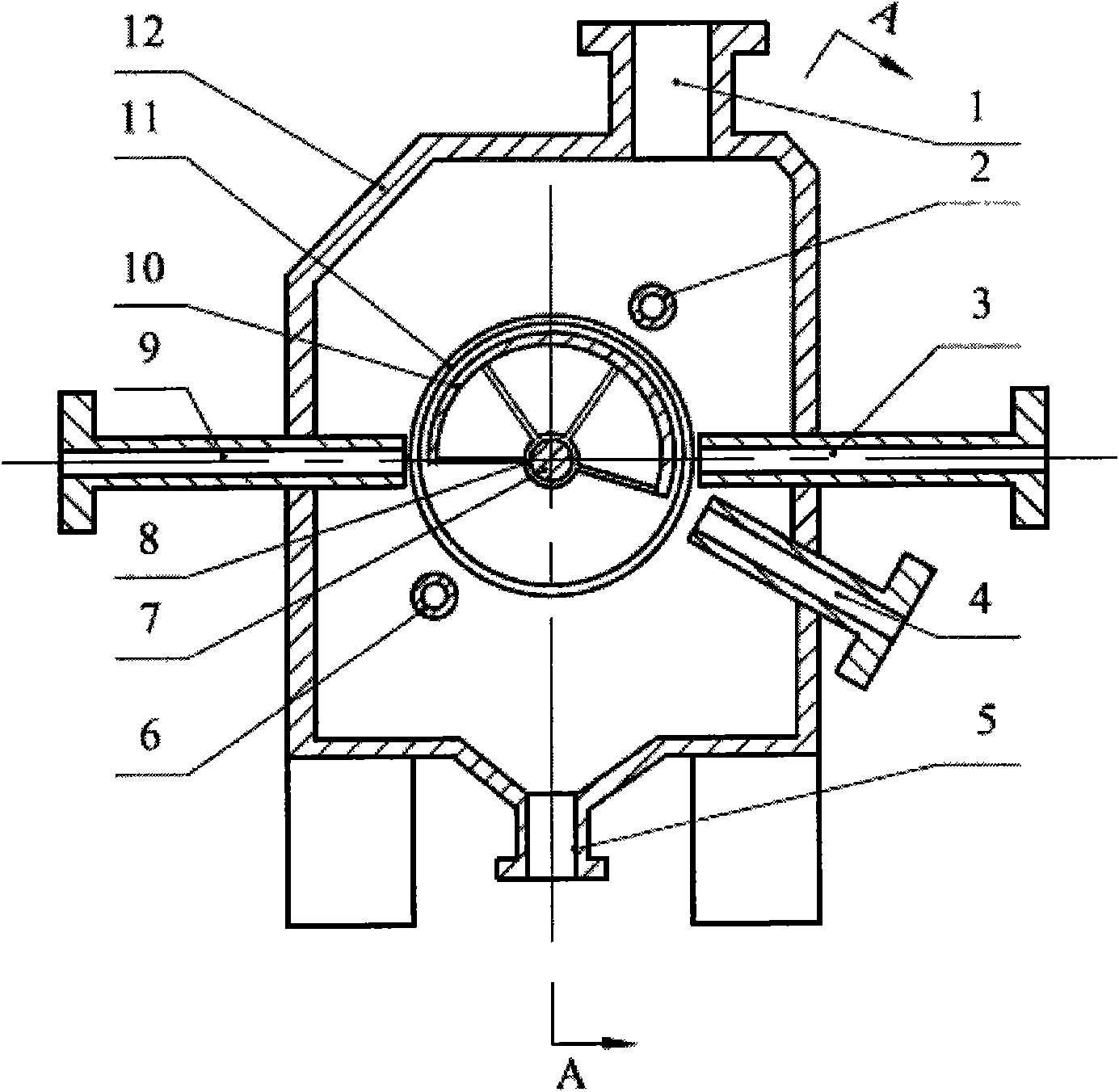

[0022] Such as figure 1 As shown: a magnetic system 10 is installed concentrically in the magnetic drum 11 , the magnetic system 10 is fixedly installed on the fixed shaft 7 through the magnet...

Embodiment 2

[0030] A micropowder dry magnetic separator, two first air ducts 2 and second air ducts 6 are installed horizontally on the upper right and lower left of the magnetic drum 11 along the axial direction of the magnetic drum 11 respectively.

[0031] Magnetic system 10 such as figure 1 As shown, the gap between the outer arc surface and the inner wall of the magnetic drum 11 is 8-10mm, the wrap angle of the magnetic system 10 is 210-220°, and the gap between the end faces on both sides of the magnetic system and the inner wall on both sides of the magnetic drum is 15-20mm.

[0032] The gap between the outer wall of the first air duct 2 and the second air duct 6 and the outer wall of the magnetic drum 11 is 10-15 mm, and the inner diameter of the first air duct 2 and the second air duct 6 is 45-50 mm; The air outlet holes of the air duct 6 have a diameter of 2 to 3 mm, and the center distance of the air outlet holes is 5 to 6 mm.

[0033] The angle between the center line of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com