Method for carrying out surface activation treatment on marine climate-resisting engineering parts

A surface activation treatment and marine climate technology, applied in gaseous chemical plating, hot-dip plating process, liquid chemical plating, etc., can solve the problems of large impact, affecting the corrosion resistance of the final coating, and poor bonding of the coating, achieving Good wear resistance, good metallurgical bonding effect, and little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Adopt the method of the present invention to prepare the operation process of anti-corrosion marine climate coating on the part surface of cast steel structure as follows:

[0048] (1) After the parts are cleaned and degreased, they are treated with pickling and rust removal, and rinsed with deionized water.

[0049] (2) Etch the degreasing and rust-removing parts in a mixed solution of hydrochloric acid HCl 94% (volume fraction) + hydrofluoric acid HF 6% (volume fraction), at room temperature for 1 minute, and rinse with deionized water.

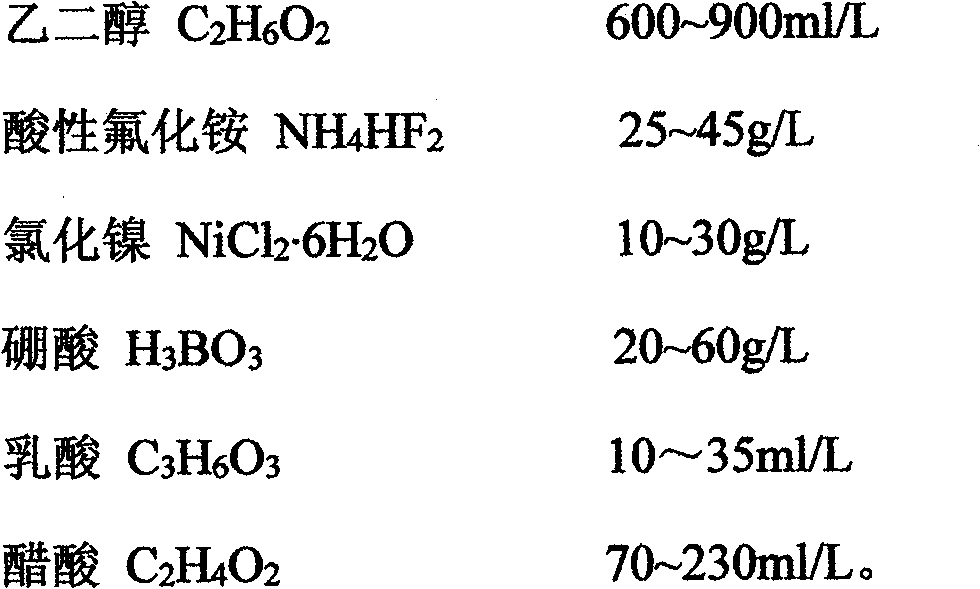

[0050] (3) Activation treatment in a mixed solution of ethylene glycol, acidic ammonium fluoride, nickel chloride, boric acid, lactic acid, and acetic acid at a temperature of 40°C for 40 minutes. Rinse with deionized water and dry.

[0051] (4) Hot-dip coating.

Embodiment 2

[0053]Adopt the method of the present invention to prepare the operation process of marine weather-resistant anticorrosion coating on the alloy steel structure part surface as follows:

[0054] (1) After the parts are cleaned and degreased, they are treated with pickling and rust removal, and rinsed with deionized water.

[0055] (2) The parts after degreasing and derusting are etched in a mixed solution of hydrochloric acid HCl 95% (volume fraction) + hydrofluoric acid HF 5% (volume fraction) at room temperature for 2 minutes, and rinsed with deionized water.

[0056] (3) Activation treatment in a mixed solution of ethylene glycol, acidic ammonium fluoride, nickel chloride, boric acid, lactic acid, and acetic acid at a temperature of 50°C for 35 minutes. Rinse with deionized water and dry.

[0057] (4) thermal spray coating.

Embodiment 3

[0059] Adopt the method of the present invention to prepare the operation process of anti-corrosion anti-corrosion coating of marine weather on the surface of steel structure parts as follows:

[0060] (1) After the parts are cleaned and degreased, they are treated with pickling and rust removal, and rinsed with deionized water.

[0061] (2) The parts after degreasing and derusting are etched in a mixed solution of hydrochloric acid HCl 96% (volume fraction) + hydrofluoric acid HF4% (volume fraction) at room temperature for 3 minutes, and rinsed with deionized water.

[0062] (3) Thermal spraying, temperature 60°C, time 30min. Rinse with deionized water and dry.

[0063] (4) Electroplating coating.

[0064] Wherein, the composition and content of the activating solution of surface activation treatment in embodiment 1-3 are as shown in Table 1 below, and it should be noted that some preferred implementations of the composition and content of the activating solution of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com