Method for simultaneously producing activated carbon and medium heating value (MHV) fuel gas by using eupatorium adenophorum

A technology for the production of activated carbon and Eupatorium adenophorum, which is applied to chemical instruments and methods, products, fuels, etc., can solve the problems of comprehensive utilization of polluted resources, shortage, high cost, etc., and achieve the effects of wide sources, large output, and reduced corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

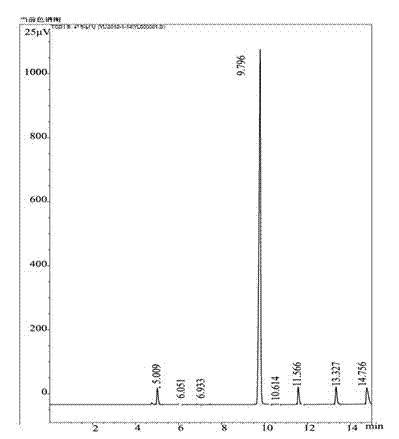

[0028] (1) After drying, Eupatorium adenophorum was heated to 550°C at a heating rate of 10°C / min for carbonization, and the carbonization time was 1.5 hours;

[0029] (2) After pulverizing the carbonized material obtained in step (1) to 30 mesh, the temperature was rapidly raised to 620°C at a heating rate of 40°C / min, and kept for 10 minutes, so that the residual volatiles were quickly volatilized and the oxidation consumption of the material was reduced. Then increase the temperature to 900°C at a rate of 10°C / min. At this time, pass carbon dioxide into the furnace and activate it for 140 minutes under the atmosphere of carbon dioxide as an activator. The flow rate of carbon dioxide is determined according to the amount of material, which is 55L / Kg·min to obtain activated carbon. Crude and medium calorific value gas;

[0030] (3) Cool the crude activated carbon obtained in step (2) to room temperature under the protection of isolated air, and then dry it at 100°C for 3 hour...

Embodiment 2

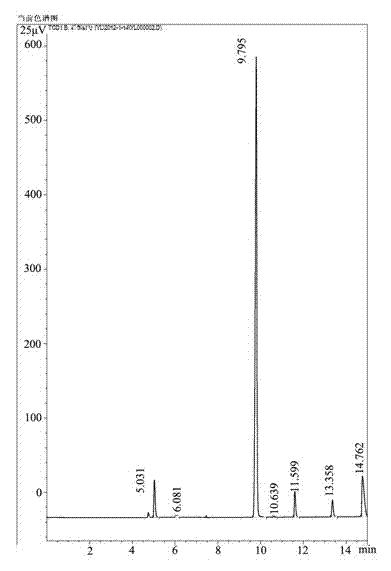

[0033] (1) After drying, Eupatorium adenophorum was heated to 600°C at a heating rate of 15°C / min for carbonization, and the carbonization time was 2 hours;

[0034](2) After the carbonized material obtained in step (1) is crushed to 35 mesh, the temperature is rapidly raised to 670°C at a heating rate of 45°C / min, and the temperature is kept for 8 minutes, so that the residual volatile matter can be quickly volatilized and the oxidation consumption of the material can be reduced. Then increase the temperature to 1000°C at a rate of 15°C / min. At this time, pass carbon dioxide into the furnace and activate it for 130 minutes under the atmosphere of carbon dioxide as an activator. The flow rate of carbon dioxide is determined according to the amount of material, which is 50L / Kg·min, and activated carbon is obtained. Crude and medium calorific value gas;

[0035] (3) Cool the crude activated carbon obtained in step (2) to room temperature under the protection of the isolated air,...

Embodiment 3

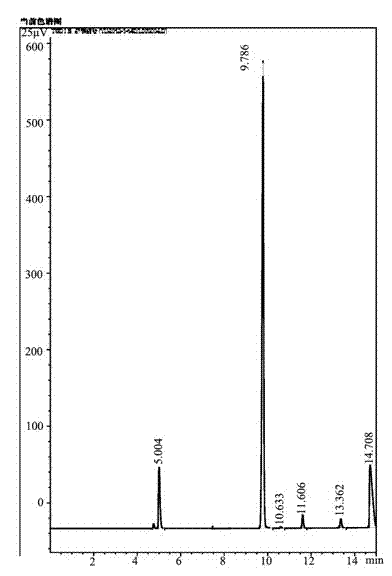

[0038] (1) After drying, Eupatorium adenophorum was heated to 630°C at a heating rate of 12°C / min for carbonization, and the carbonization time was 2.5 hours;

[0039] (2) After pulverizing the carbonized material obtained in step (1) to 40 mesh, rapidly raise the temperature to 700°C at a heating rate of 42°C / min, and keep it warm for 5 minutes, so as to quickly volatilize the residual volatile matter and reduce the oxidation consumption of the material. Then heat up to 960°C at a heating rate of 12°C / min. At this time, pass carbon dioxide into the furnace and activate for 120 minutes under the atmosphere of carbon dioxide as an activator. The flow rate of carbon dioxide is determined according to the amount of material, which is 80L / Kg·min, and activated carbon is obtained. Crude and medium calorific value gas;

[0040] (3) Cool the crude activated carbon obtained in step (2) to room temperature under the protection of isolated air, and then dry it at 110°C for 2 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine adsorption value | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com