Method for preparing high-purity cadmium telluride

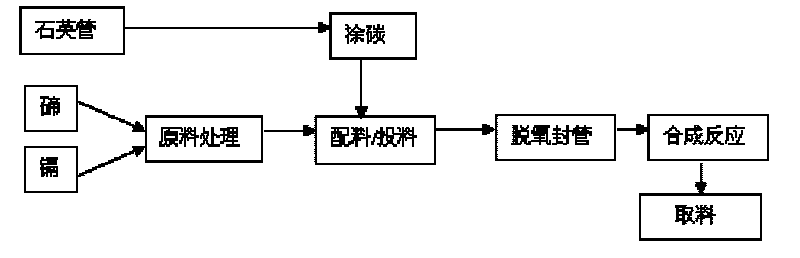

A cadmium telluride, high-purity technology, applied in the direction of binary selenium/tellurium compounds, can solve the problems of high cost of powder raw materials, sufficient reaction, loss of raw materials, etc., to ensure synthesis rate and purity, avoid direct contact, and avoid oxidation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 The preparation method of the first high-purity cadmium telluride comprises the following steps:

[0050] (1) Quartz tube coated with carbon

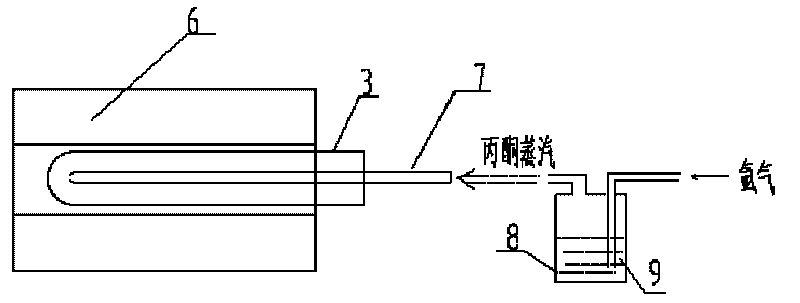

[0051] Such as image 3 As shown, when the furnace temperature of the deoxidation furnace 6 reaches 800° C., the vent pipe 7 is fixed, and argon gas is introduced at a rate of 0.5 liters per minute, and the acetone 9 starts to bubble, and the acetone vapor is brought into the vent pipe 7 . Acetone comes out from the vent tube and is cracked under high temperature conditions. At the same time, move the vent tube or the cleaned quartz tube 3 at a speed of 10 cm / 10 seconds, and form a layer of carbon film on the quartz tube wall.

[0052] (2) Raw material handling

[0053] Select cadmium ingots with a particle size smaller than the inner wall of the quartz tube with a purity of 5N;

[0054] Use an agate stick to smash the 5N tellurium raw material in an agate bowl, so that the particle size is within 0.35-10mm for us...

Embodiment 2

[0067] Embodiment 2: the preparation method of the second kind of high-purity cadmium telluride, comprises the following steps:

[0068] (1) Quartz tube coated with carbon

[0069] Such as image 3 As shown, when the furnace temperature of the deoxidation furnace 6 reaches 1100° C., the vent pipe 7 is fixed, and argon gas is introduced at a rate of 0.8 liters per minute, and the acetone 9 starts to bubble, and the acetone vapor is brought into the vent pipe 7 . Acetone comes out from the vent tube and is cracked under high temperature conditions. At the same time, move the vent tube or the cleaned quartz tube 3 at a speed of 15 cm / 10 seconds to form a layer of carbon film on the quartz tube wall.

[0070] (2) Raw material handling

[0071] Select cadmium ingots with a particle size smaller than the inner wall of the quartz tube with a purity of 5N;

[0072] Use an agate stick to smash the 5N tellurium raw material in an agate bowl, so that the particle size is within 10-20m...

Embodiment 3

[0085] Embodiment 3: the preparation method of the third kind of high-purity cadmium telluride, comprises the following steps:

[0086] (1) Quartz tube coated with carbon

[0087] Such as image 3 As shown, when the furnace temperature of the deoxidation furnace 6 reaches 900°C, the vent pipe 7 is fixed, and argon gas is introduced at a rate of 1 liter / minute, and the acetone 9 starts to bubble, and the acetone vapor is brought into the vent pipe 7. Acetone comes out from the vent tube and is cracked under high temperature conditions. At the same time, move the vent tube or the cleaned quartz tube 3 at a speed of 20 cm / 10 seconds to form a layer of carbon film on the quartz tube wall.

[0088] (2) Raw material handling:

[0089] Select cadmium ingots with a particle size smaller than the inner wall of the quartz tube with a purity of 5N;

[0090] Use an agate rod to crush the 5N tellurium raw material in an agate bowl, so that the particle size is within 0.35-0.5 mm for use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com