Halogen-free and cleaning-free soldering flux for lead-free solder

A lead-free solder and flux technology, applied in the direction of welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of excessive rosin addition, increased residue, increased solid content, etc., to achieve high surface insulation resistance, The solder joints are full and smooth, and the effect of not polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

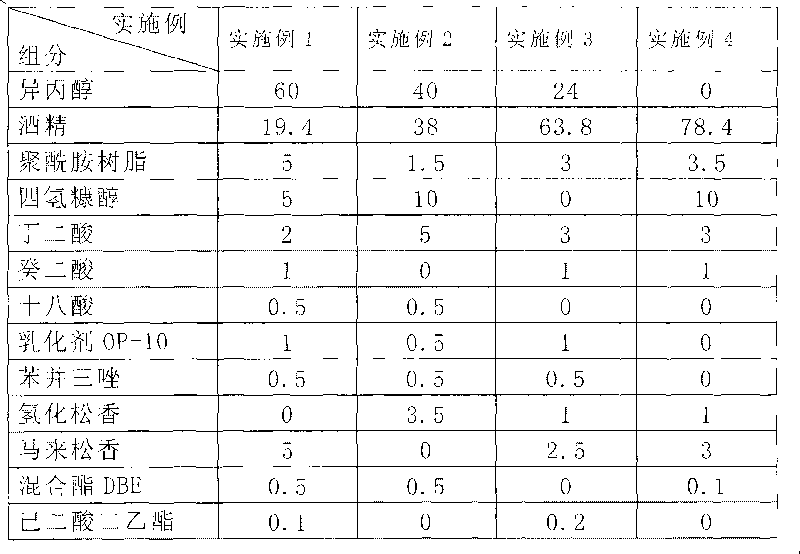

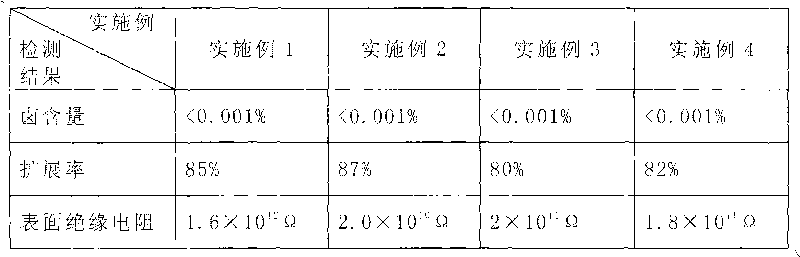

Examples

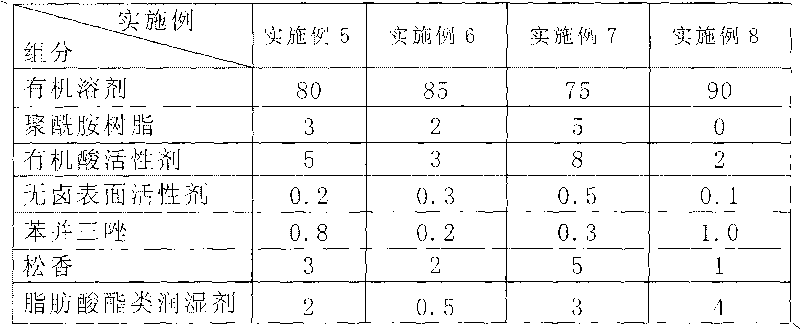

Embodiment 6

[0028] The organic solvent described in embodiment 6 is diethylene glycol ethyl ether and propylene glycol methyl ether, and the weight ratio of the two is 4: 1; Described organic acid active agent is phthalic acid, palmitic acid and racemic malic acid, The ratio of the three is 1:1:1; the halogen-free surfactant is emulsifier OP-10 and triethanolamine, and the weight ratio of the two is 2:1; the rosin is disproportionated rosin, partially polymerized rosin , hydrogenated rosin glyceride and pentaerythritol rosin ester, the weight ratio of the four is 1:1:1:1. The fatty acid ester wetting agent is benzyl acetate and dimethyl succinate, and the weight ratio of the two is 3:2.

Embodiment 7

[0029] The organic solvent described in Example 7 is tetrahydrofurfuryl alcohol; the organic acid activator is palmitic acid; the halogen-free surfactant is emulsifier OP-10, and the rosin is hydrogenated rosin, acrylic rosin And maleic rosin, the weight ratio of the three is 2:1:1. , the fatty acid ester wetting agent is diethyl succinate and dimethyl glutarate, the weight ratio of the two is 2:1.

Embodiment 8

[0030] The organic solvent described in Example 8 is 2-methyl-hexanediol, the organic acid active agent is racemic malic acid, and the halogen-free surfactant is emulsifier OP-10 and triethanolamine, both The weight ratio of the two is 3:1; the rosin is polymerized rosin and hydrogenated rosin, and the weight ratio of the two is 1:1; the fatty acid ester wetting agent is dimethyl adipate, ethyl benzoate and benzyl benzoate, the weight ratio of the three is 1:2:1.

[0031] Put all the components weighed in Examples 1-8 into the flux reactor, stir for 100-120 minutes until all the components are dissolved, and then obtain the halogen-free no-cleaning for lead-free solder described in Examples 1-8 flux.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com