Lithium ion battery cathode material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as difficulty in large-scale production, complex preparation processes, and complex product components, and achieve a wide range of metal types and materials. The effect of low preparation cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 10g of analytically pure resorcinol and 20g of ferrocene according to a mass ratio of 1:2, mix with 200ml of acetone solvent and stir until uniform, then dry in a constant temperature water bath at 40°C until the acetone is completely volatilized to obtain a solid, and place the solid in In a high pressure reactor. Heating is carried out under the protection of nitrogen, and the heating rate is maintained at 3°C / min. When the temperature rises from normal temperature to 450°C, the heating is stopped. When the temperature drops to normal temperature, pyrolysis products are obtained.

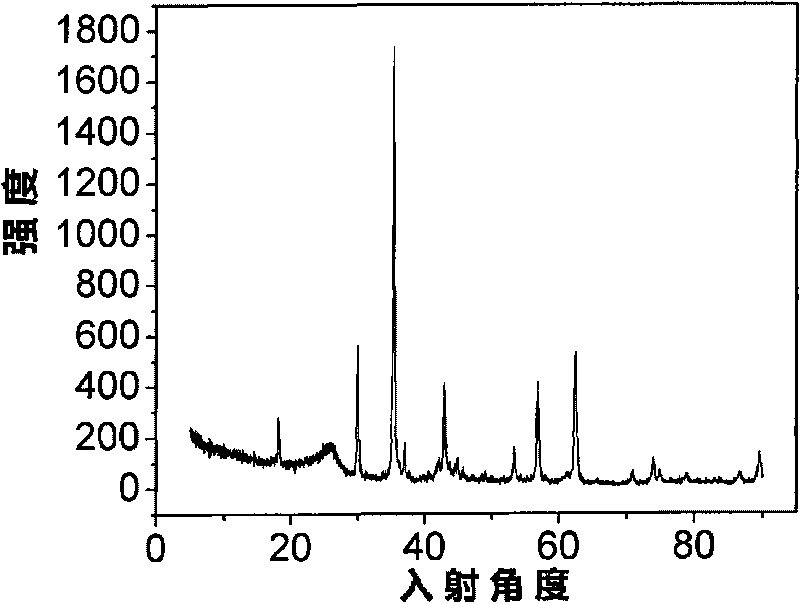

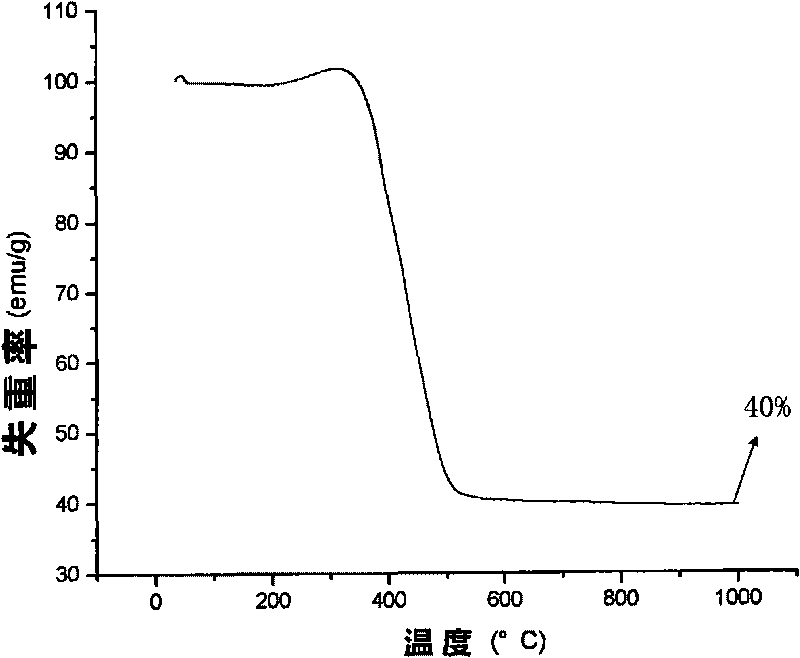

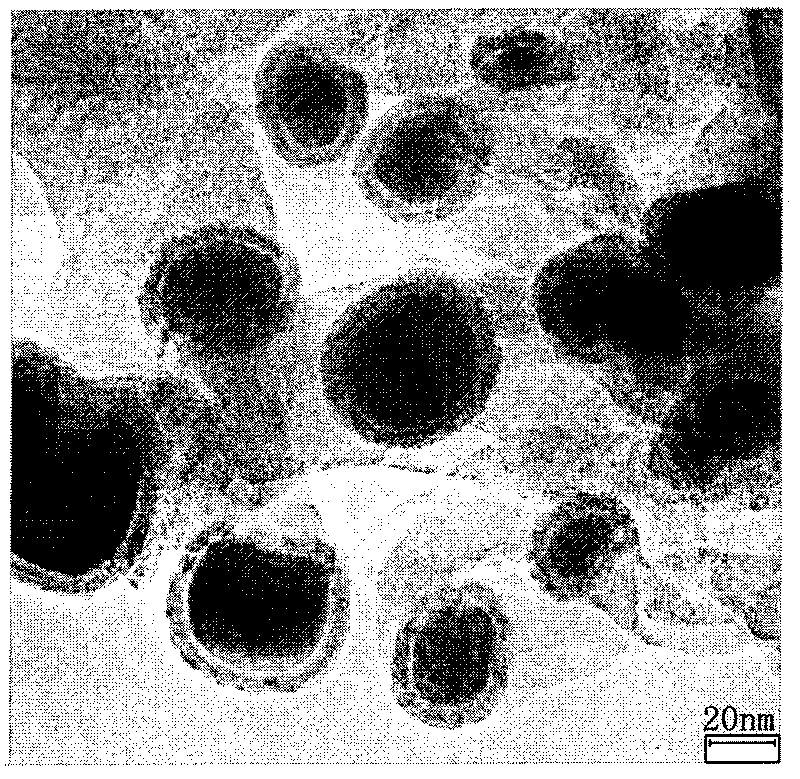

[0037] Using pyridine as a solvent, at a temperature of 120°C, the pyrolysis product was repeatedly washed and extracted until the filtrate became colorless and clear. The filter residue after drying is carbon-coated nano-Fe 3 o 4 Composite material with a yield of 68%. Through thermogravimetric analysis, it is obtained that this material contains Fe 3 o 4 was 39.8%.

[0038] Su...

Embodiment 2

[0042] The operation method is the same as in Example 1. Weigh 10 g of analytically pure benzaldehyde and 20 g of iron acetylacetonate according to a mass ratio of 1:2, add them to 200 ml of ethanol solvent, mix and stir until uniform, and then dry in a constant temperature water bath at 40 ° C until the ethanol is completely volatilized A solid was obtained, and the solid was placed in an autoclave. Heating is carried out under the protection of nitrogen, and the heating rate is maintained at 3°C / min. When the temperature rises from normal temperature to 450°C, the heating is stopped immediately. When the temperature drops to room temperature, pyrolysis products are obtained, and the system self-increasing pressure finally reaches 6.0Mpa.

[0043] Using pyridine as a solvent, at a temperature of 120°C, the pyrolysis product was repeatedly washed and extracted until the filtrate became colorless and clear. Finally, the carbon-coated nano-Fe3O4 composite material with particle ...

Embodiment 3

[0045] Weigh 10 g of analytically pure isophthalic acid and 20 g of ferrocene according to a mass ratio of 1:2, and the other steps are the same as in Example 1. Finally, carbon-coated nano-Fe with a particle size distribution of 20-80nm is obtained 3 o 4 The composite material is analyzed by thermogravimetric analysis, and the content of metal oxide in the material is 38.3%. Using the same method as in Example 1 to carry out charge and discharge tests, the results show that the negative electrode material exhibits good cycle stability, the first discharge capacity is as high as 985mAh / g, and the capacity can be maintained after 30 cycles at a current density of 50mA / g. At 379mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com