Method for recovering copper and nickel from plastic chromium coatings

A technology of chrome plating and copper recovery, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of difficult recovery of valuable metals, high recovery cost, environmental impact, etc., and achieve low cost, small environmental pollution, and leaching high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

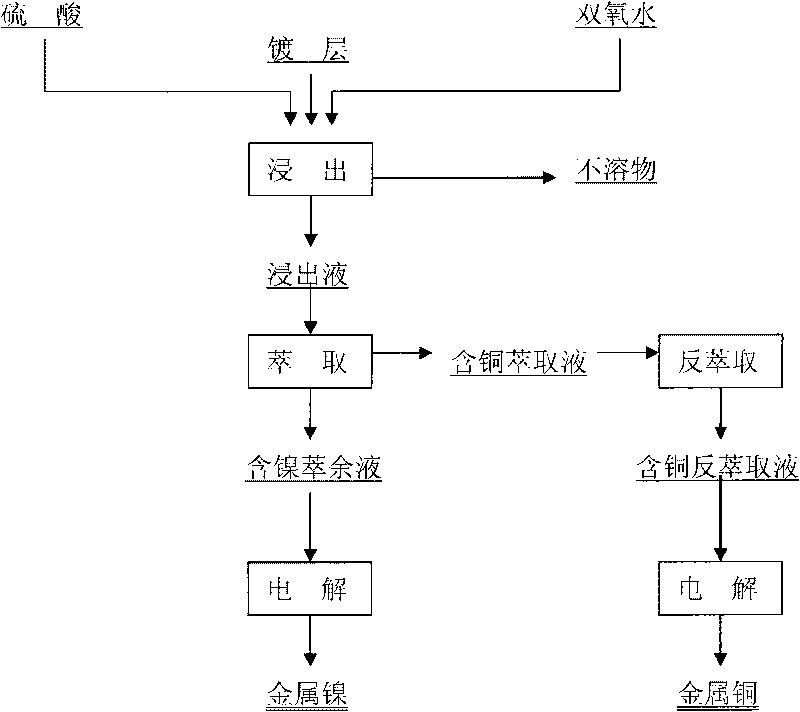

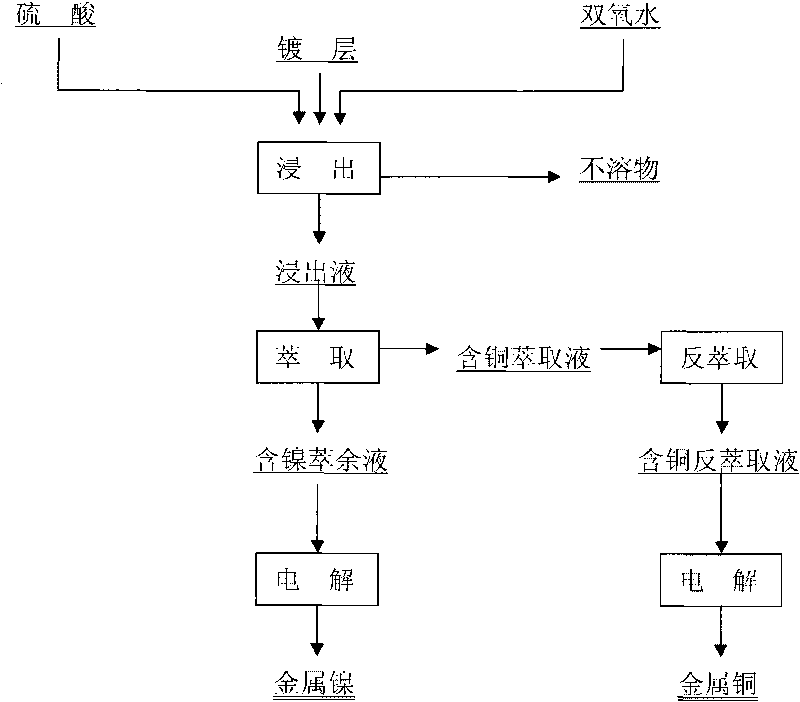

Method used

Image

Examples

Embodiment 1

[0010] Weigh 80g of the coating, wherein Cu and Ni contents are 44.2% and 53.6% respectively, add 1L of 1.5mol / L H 2 SO 4 and 1mol / LH 2 o 2 The mixed solution has a liquid-solid ratio of 12.5:1. At room temperature, the leaching time is 30 minutes. After filtration, 1210ml of leachate is obtained. The concentrations of Cu, Ni and Cr in the leachate are 28.9g / L, 35.4g / L and 0.004g / L respectively. , to obtain 2.2 g of insoluble matter, whose Cu, Ni and Cr contents were 11.8%, 1.1% and 87.1%, respectively. The leaching rates of Cu and Ni reach 98.9% and 99.9% respectively.

[0011] At room temperature, the above leaching solution was added with a concentration of 7mol / L ammonia to adjust the pH=3, and the volume fraction was 15%, and the molar ratio was 1:1 2-hydroxyl-5-dodecyl salicylaldoxime and 2- Hydroxy-5-nonylacetophenone oxime mixture was used as extractant, extracted for 10min, and obtained copper-containing extract and 1350ml nickel-containing raffinate, wherein Cu a...

Embodiment 2

[0015] Weigh 80g of coating, wherein Cu and Ni contents are 40.8%, 34.7% and respectively, add 2L of 1mol / L H 2 SO 4 and 0.5mol / LH 2 o 2 The mixed solution has a liquid-solid ratio of 25:1. At room temperature, the leaching time is 60 minutes. After filtration, 2360ml of leachate is obtained. The concentrations of Cu, Ni and Cr in the leachate are 13.6g / L, 11.7g / L and 0.002g / L respectively. , to obtain 19.8 g of insoluble matter whose Cu, Ni and Cr contents were 0.9%, 0.2% and 98.5%, respectively. The leaching rates of Cu and Ni reach 98.5% and 99.6% respectively.

[0016] At room temperature, the above leaching solution was added with a concentration of 7mol / L ammonia to adjust the pH=2, and the volume fraction was 30%, and the molar ratio was 1:1 of 2-hydroxyl-5-dodecyl salicylaldoxime and 2- Hydroxy-5-nonylacetophenone oxime mixture was used as extractant, extracted for 20min, and obtained copper-containing extract and 2570ml nickel-containing raffinate, wherein Cu and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com