Preparation method of carbon nano tube-copper oxide composite powder

A technology of carbon nanotubes and copper oxides, which is applied in the direction of liquid chemical plating, coating, metal material coating technology, etc., can solve the problems that the thickness of the coating is difficult to control, and the carbon nanotubes are difficult to form a complete and continuous coating, so as to achieve improvement Activation ability, side reaction avoidance, wettability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

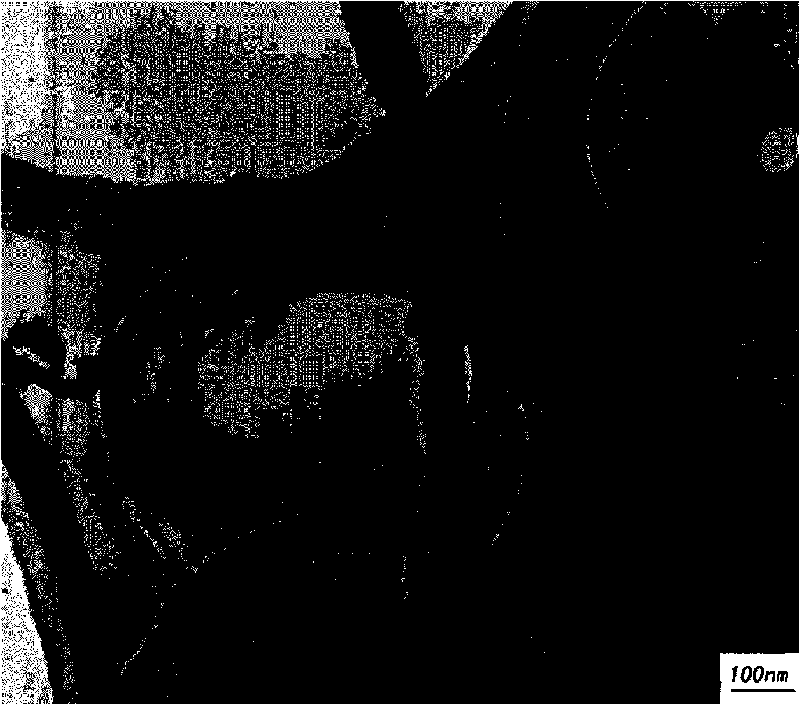

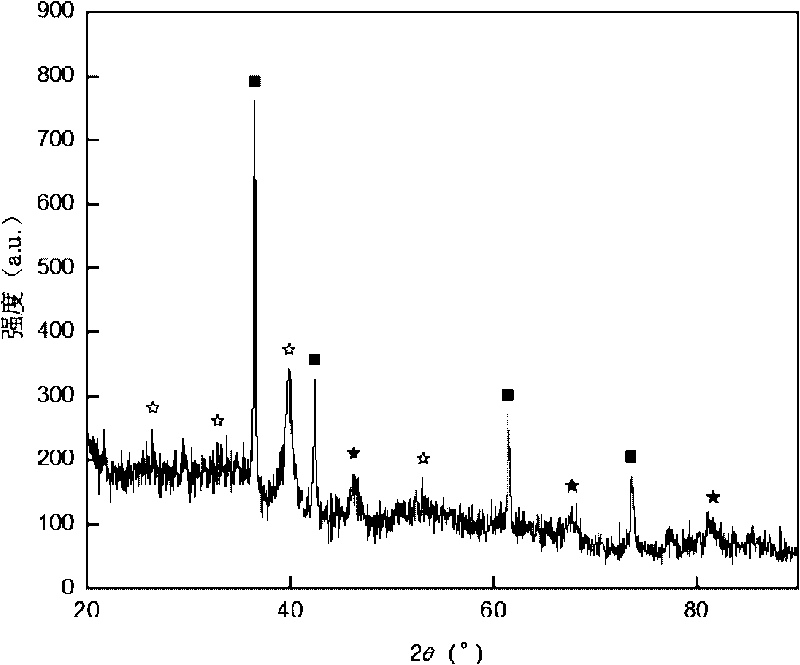

[0009] Specific embodiment one: the preparation method of the carbon nanotube-copper oxide composite powder in this embodiment is carried out according to the following steps: the preparation method of the carbon nanotube-copper oxide composite powder is carried out according to the following steps: The carbon nanotubes are pretreated by the steps of oxidation, sensitization and activation in sequence; then the pretreated carbon nanotubes are placed in a plating solution with a constant temperature of 15-25°C for ultrasonic treatment to perform electroless copper oxide plating for 30min- 3h; then filter with a microporous membrane, wash with water until the pH value is 7.0; then put it into a drying box, and dry it in an air atmosphere at a temperature of 105°C for 24 hours to obtain a carbon nanotube-copper oxide composite powder body; where the plating solution is proportionally composed of 16gCuSO 4 ·5H 2 O, 40gNaKC 4 h 4 o 6 4H 2 O, 12mL HCHO, 2g NiCl 2 ·6H 2 O, 40m...

specific Embodiment approach 2

[0010] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the oxidation treatment is to mix concentrated sulfuric acid and concentrated nitric acid at a volume ratio of 3:1 to obtain a mixed acid, put carbon nanotubes into it, and Stir under magnetic force for 24 hours, then dilute with distilled water 20-40 times the volume of the mixed acid, then filter with a microporous membrane, and then wash with distilled water until the pH value of the filtered solution is equal to 6.5-7. Other steps and parameters are the same as in the first embodiment.

[0011] In this embodiment, the concentration of concentrated sulfuric acid used to prepare the mixed acid is 98% (weight), and the concentration of concentrated nitric acid is 68-70% (weight).

specific Embodiment approach 3

[0012] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the oxidation treatment is to put the carbon nanotubes into concentrated nitric acid with a mass concentration of 68-70%, and stir and reflux at 120°C for 10 hours . Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com