Preparation method for Bi-2212 high-temperature superconducting wires

A bi-2212, high-temperature superconducting technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the limitation of wire current carrying performance, wire performance degradation, poor grain arrangement, etc. problem, to achieve the effect of high practical value, low manufacturing cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

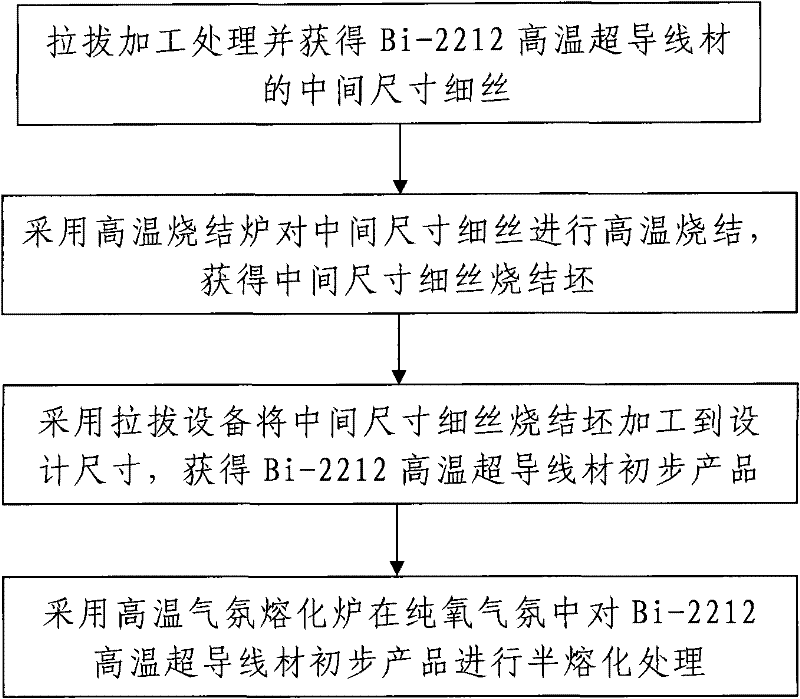

[0023] Such as figure 1 Shown, the preparation method of a kind of Bi-2212 high temperature superconducting wire of the present invention comprises the following steps:

[0024] Step 1, drawing processing and obtaining intermediate-sized filaments of the Bi-2212 high temperature superconducting wire rod, the drawing processing process is as follows:

[0025] 101. Fill the pure silver tube with Bi-2212 superconducting powder until it is full, and close the two ends of the pure silver tube with metal plugs to make a composite;

[0026] 102. Use drawing equipment to draw the primary complex into filaments 1 with a diameter of Φ1.5-2.2 mm, and then use cutting equipment to cut the filaments into 55-91 segments on average, and then cut the filaments into 55-91 segments. The cut filaments of 55-91 segments are arranged in a regular hexagonal arrangement and assembled into a pure silver tube to obtain a secondary composite with 55-91 cores; the inner diameter of the pure silver tube...

Embodiment 1

[0032] In this embodiment, when preparing the Bi-2212 high temperature superconducting wire, the preparation process includes the following steps:

[0033] Step 1, drawing processing and obtaining intermediate-sized filaments of the Bi-2212 high temperature superconducting wire rod, the drawing processing process is as follows:

[0034] 101. Fill the pure silver tube with Bi-2212 superconducting powder until it is full, and close the two ends of the pure silver tube with metal plugs to make a composite;

[0035]102. Use drawing equipment to draw the primary complex into filaments 1 with a diameter of Φ1.92 mm, and then use cutting equipment to cut the filaments into 61 segments on average, and then cut the 61 segments The filaments are arranged in a regular hexagonal arrangement and assembled into a pure silver tube to obtain a 61-core secondary composite; the inner diameter of the pure silver tube corresponds to the size of the regular hexagonal structure formed by an arrange...

Embodiment 2

[0041] In this embodiment, the difference from Embodiment 1 is that in step 102, drawing equipment is used to draw the primary composite body into a filament with a diameter of Φ1.94mm, and secondly, a cutting device is used to cut the filament into a Cut into 55 segments on average, and then arrange the 55 segments of filaments according to the regular hexagonal arrangement and assemble them into the pure silver tube to obtain a 55-core secondary composite; The dimensions of the regular hexagonal structure composed of filaments correspond to each other;

[0042] In step 103, drawing equipment is used to draw the 55-core secondary complex into filaments 2 with a diameter of Φ5mm, and then cutting equipment is used to cut the filaments 2 into 7 sections on average, and then the 7 sections cut into The two filaments are arranged in a regular hexagonal arrangement and assembled into the AgMn alloy tube to obtain a tertiary composite with 385 cores; the inner diameter of the AgMn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com