Multi-layer composite passivation layer structure of bipolar circuit and its production process

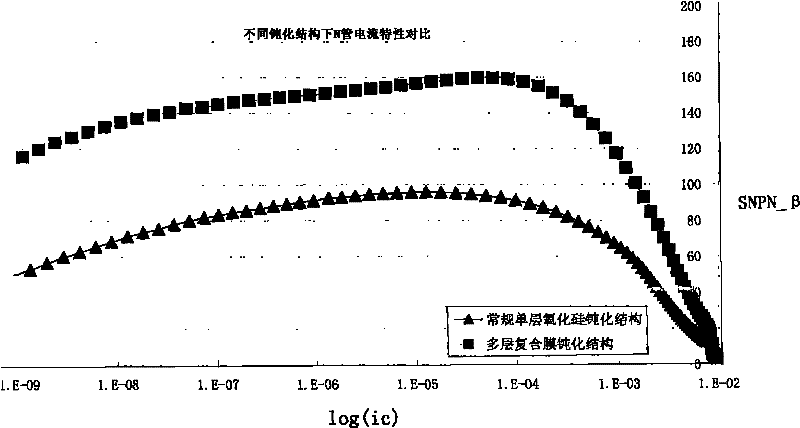

A multi-layer composite and generation process technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of limited application, poor photoelectric performance, and poor step coverage ability, so as to improve the small current amplification factor and avoid stress migration , improve the effect of linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

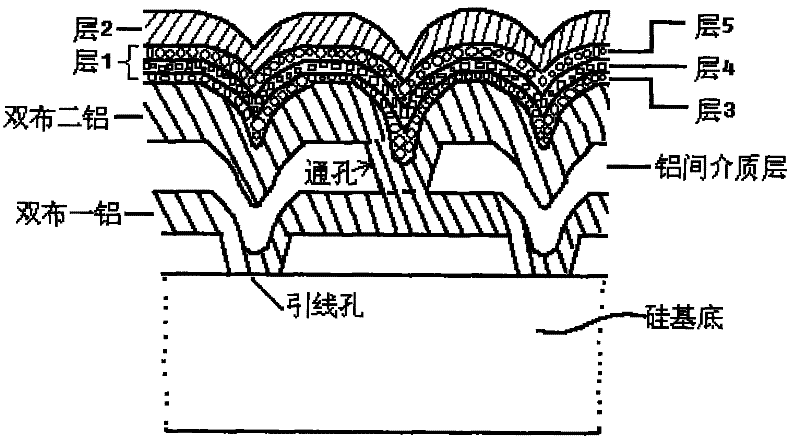

[0019] The content of the present invention will be further described below with reference to the accompanying drawings and taking a photoelectric conversion integrated circuit as an embodiment.

[0020] The multilayer composite passivation film structure of Bipolar circuit, such as figure 1 As shown, it includes a bottom silicon oxide thin film layer (1) deposited on the silicon substrate surface and a silicon nitride thin film layer (2) deposited on the silicon oxide thin film layer (1), and the silicon oxide thin film layer ( 1) is mixed with a certain proportion of phosphine, and the proportion of phosphine in the silicon oxide film layer is 3% to 5%, and the silicon oxide film layer (1) is followed by an undoped silicon dioxide layer (3), doped impurity phosphosilicate glass layer (4), non-doped silicon dioxide layer (5), the silicon substrate surface has double cloth-aluminum, aluminum interlayer dielectric layer, double cloth two aluminum. Among them, the silicon nitri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com