Wearable ultrahigh molecular weight polyethylene tubular product and preparation method thereof

A technology of ultra-high molecular weight, polyethylene pipes, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of low thermal deformation temperature, low mechanical strength, poor high temperature resistance, etc., and achieve chemical stability High resistance, good non-adhesion, excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 A kind of manufacturing method of wear-resistant ultra-high molecular weight polyethylene pipe of the present invention,

[0041] Including the following steps:

[0042] a. mix

[0043] Accurately weigh 95.35 parts by weight of ultra-high molecular weight polyethylene with a viscosity-average molecular weight of 2.8 million, 4.5 parts by weight of polyethylene wax with a molecular weight of 1500, and 0.15 parts by weight of carbon black, mix well, and set aside;

[0044] b. Extrusion molding

[0045] Using a single-screw extrusion system, under the pressure of 30MPa, continuous extrusion molding is used to produce wear-resistant ultra-high molecular weight polyethylene pipes.

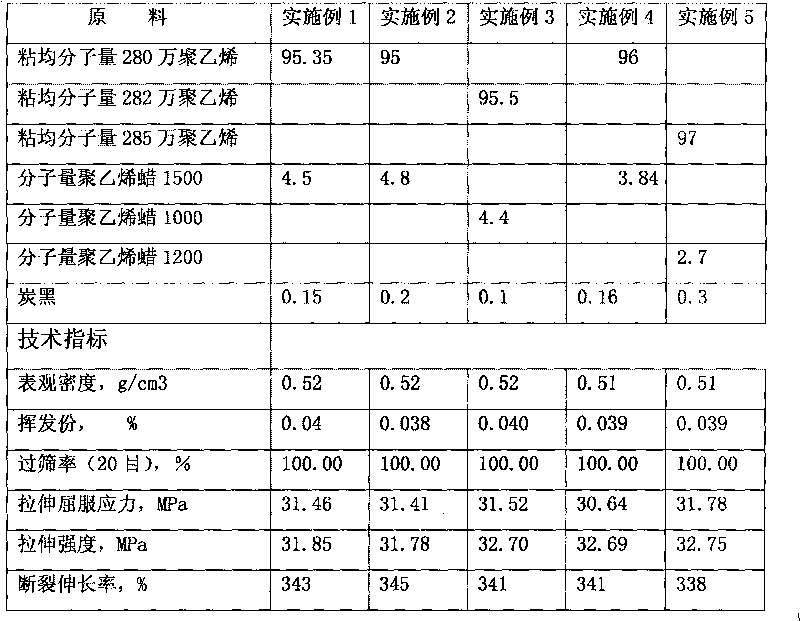

[0046] Examples 2-7 According to the method and steps of Example 1, the wear-resistant ultra-high molecular weight polyethylene pipe of the present invention was manufactured using the formula in Table 1 in parts by weight of raw materials.

[0047] Table 1

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com