Application of sodium butyl

A technology of sodium butyrate and minimum inhibitory concentration, used in the field of feed mildew inhibitor and mildew inhibitor, can solve the problems of good light resistance and heat resistance, low effective use concentration, unclear inhibitory concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

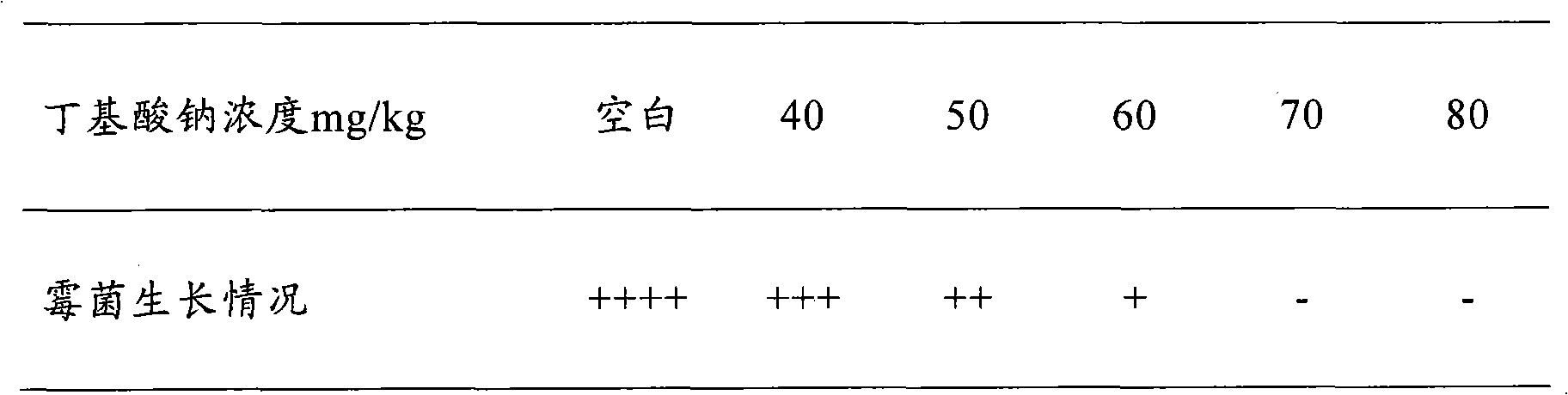

[0023] Embodiment 1 Sodium butyrate measures the minimum inhibitory solubility (MIC) of mold in feed

[0024] 1.1 Preparation of mold spore suspension

[0025] Weigh 25g of chicken feed with mold, which is purchased from the Feed Processing Laboratory of Nanjing Agricultural University, Animal Science and Technology College, put into a conical flask containing 250ml of sterilized normal saline, vibrate on a shaker for 30min, and use a 10ml pipette to Dilute 10ml of the above-mentioned physiological saline with mold at 1:10 in a 25ml test tube, and blow and suck repeatedly 50 times with an ear wash ball and a 1ml pipette to disperse the mold spores. Take 1ml of the dilution with mold and add 9ml of physiological saline, and mix thoroughly to obtain a dilution of 1:100 with mold. Take 1ml of the 1:100 dilution with mold, add it to 100ml of sterilized saline, and mix thoroughly to obtain a 1:10000 dilution with mold (this dilution contains approximately 100 mold colonies per ml)...

Embodiment 2

[0033] The inhibitory effect of embodiment 2 sodium butylate to six different molds

[0034] Six kinds of standard experimental bacteria: Aspergillus flavus, Aspergillus fumigatus, Penicillium solanum, Penicillium inmanica, Fusarium moniliforme and Fusarium graminearum were purchased from China General Microbiology Collection Center.

[0035] 1.1 Strain recovery culture

[0036] Use a sterile pipette to draw 0.3-0.4ml of a suitable liquid medium glucose-peptone soup, drop it into an ampoule tube with the corresponding strain, and shake gently to dissolve the freeze-dried bacteria into a suspension; take about 0.2ml of bacteria Somatic suspension, transplanted on the designated agar slant / plate medium, cultured for 5 days.

[0037] 1.2 Plate preparation

[0038] Take 0.1g, 0.125g, 0.15g, 0.175g, and 0.2g of sodium butylate respectively in a 250ml sterilized Erlenmeyer flask, add 100ml of sterilized normal saline, place the shaker for 30min, take it off, and put it in an elect...

Embodiment 3

[0041] The influence of embodiment 3pH value on inhibitory effect of sodium butylate

[0042] 1.1 Preparation of media with different pH values

[0043] Adjust the pH of the culture medium (species) to 5.5 and 7.5 with 0.1 mol / L sodium hydroxide.

[0044]1.2 Preparation of plates: take 0.1g, 0.125g, 0.15g, 0.175g, 0.2g, 0.225g, 0.25g, 0.275g of sodium butylate (Jiangsu Tiancheng Biochemical Products Co., Ltd. g, 0.3g, 0.325g, and 0.35g are placed in a 250ml sterilized Erlenmeyer flask, add 100ml of sterilized normal saline, put it on the shaker for 30min, take it off, put it on an electric furnace and heat it to about 50°C for 3-5min , to fully dissolve sodium butyrate, add 1ml each to a sterile petri dish, pour 19ml of each pH medium sterilized at about 45°C, mix well and wait for it to solidify, the final concentration is: 40mg / kg, 50mg / kg kg, 60mg / kg, 62mg / kg, 88mg / kg, 90mg / kg, 100mg / kg, 110mg / kg, 120mg / kg, 130mg / kg, 140mg / kg. A control group of each pH value was set up,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com