Method for microwave chemical modification treatment of wool

A technology of microwave chemistry and treatment method, applied in the field of microwave chemical modification treatment of wool, can solve the problems of high energy consumption, yellowing of fibers, environmental pollution, etc., and achieve the effects of preventing environmental pollution, improving dyeing performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The microwave urea modification treatment method for wool comprises the steps of: soaking the wool in a finishing solution containing 200g / L urea for 20 minutes, two dipping and two rolling, the excess rate is 70%, and then putting the wool fabric in a microwave device for irradiating for 1 minute , with a microwave power of 300W, fully washed in hot water at 50°C, washed in cold water, and finally dried.

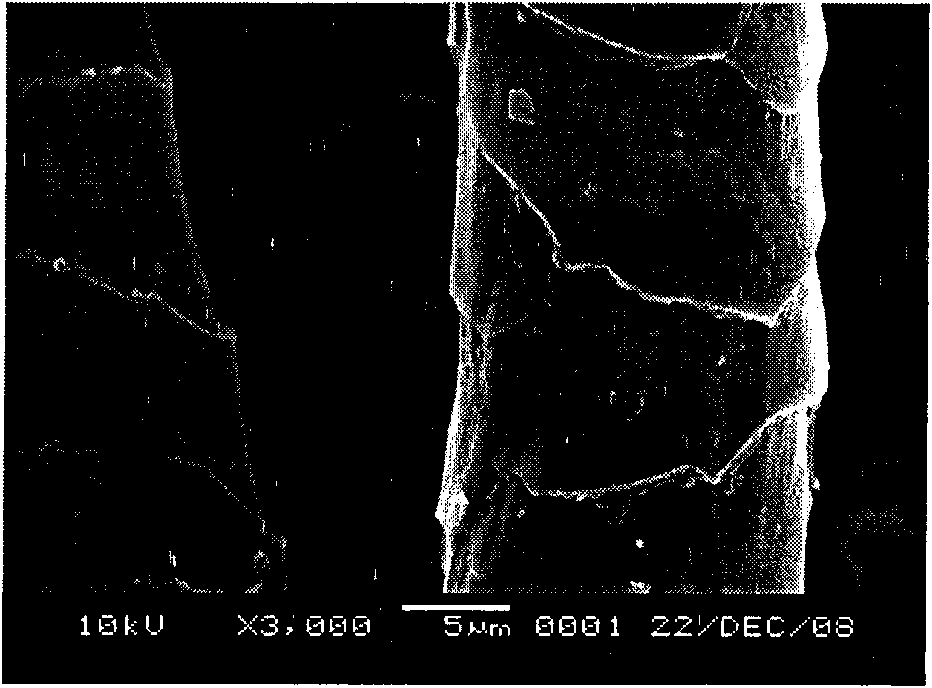

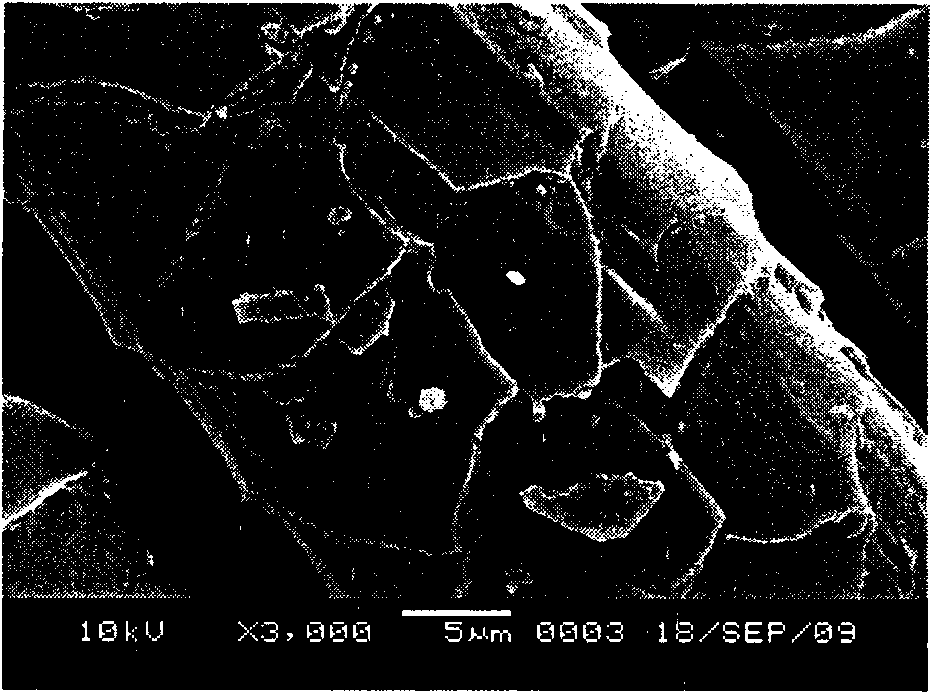

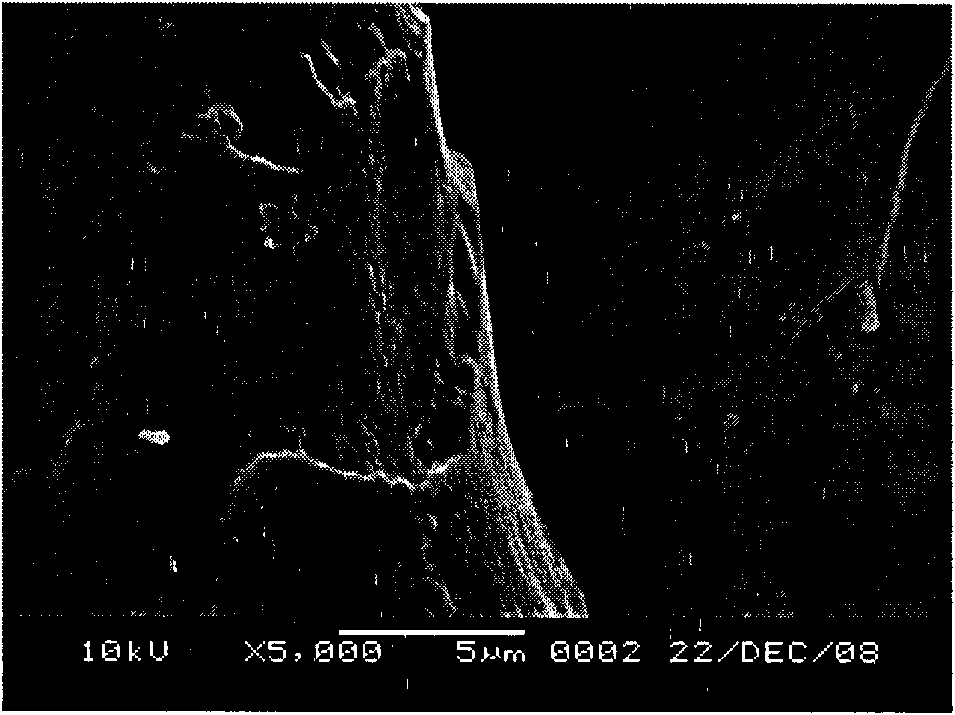

[0028] Microwave / urea treatment increased the roughness of the wool fiber surface by SEM photos after modification treatment.

Embodiment 2

[0030] The microwave ammonia salt modification treatment method of wool comprises the steps of: soaking the wool in a finishing solution containing 0.4mol / L ammonia water and 8g / L sodium chloride for 20 minutes, two dipping and two rolling, the excess rate is 70%, and then Put the woolen fabric into a microwave device for 3 minutes and irradiate it with a microwave power of 300W, fully wash it in hot water at 50°C, wash it in cold water, and finally dry it.

Embodiment 3

[0032] The microwave hydrogen peroxide modification treatment method of wool comprises the steps of: soaking the wool in a finishing solution containing 30ml / L hydrogen peroxide, 0.7% sodium silicate and 0.2% anhydrous sodium carbonate for 20 minutes, two dipping and two rolling, and the excess rate is 70% %, and then put the wool fabric into a microwave device for 3 minutes of irradiation, the microwave power is 700W, fully washed in hot water at 50°C, washed in cold water, and finally dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com