Biomass gasification fired boiler

A biomass and boiler technology, applied in the field of boilers, can solve the problems of low thermal efficiency of boilers, poor combustion stability, and high concentration of smoke and dust emissions, and achieve the effects of reducing labor intensity, scientific feeding and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

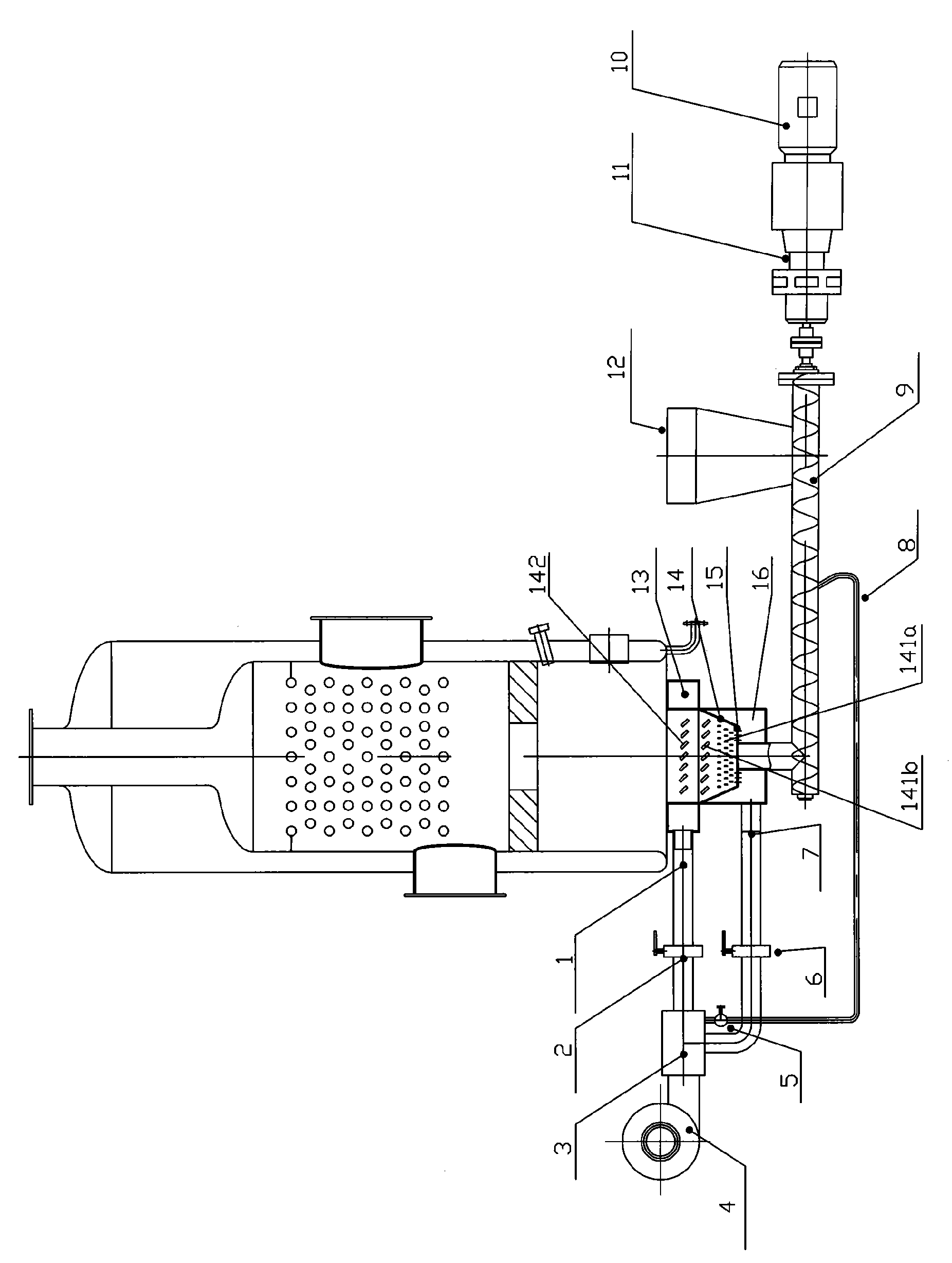

[0034] A biomass gasification combustion boiler with a boiler output of 300kg / h, such as figure 1 As shown, it includes a furnace body, a blower, an air duct, a feeding device and a biomass burning device, and is characterized in that:

[0035] The air duct includes: a primary air duct 1 and a secondary air duct 7, and a butterfly valve 3 and a butterfly valve 6 are installed respectively; the blower 4 is connected to the primary air duct 1 and the secondary air duct 7 through a tee 3;

[0036] Described biomass burning device comprises:

[0037] The primary air box 16 is located at the bottom of the combustion device, and its central position is connected with the feeding device, and is connected with the primary air pipe 7 through the primary air inlet at the lower part of the side wall;

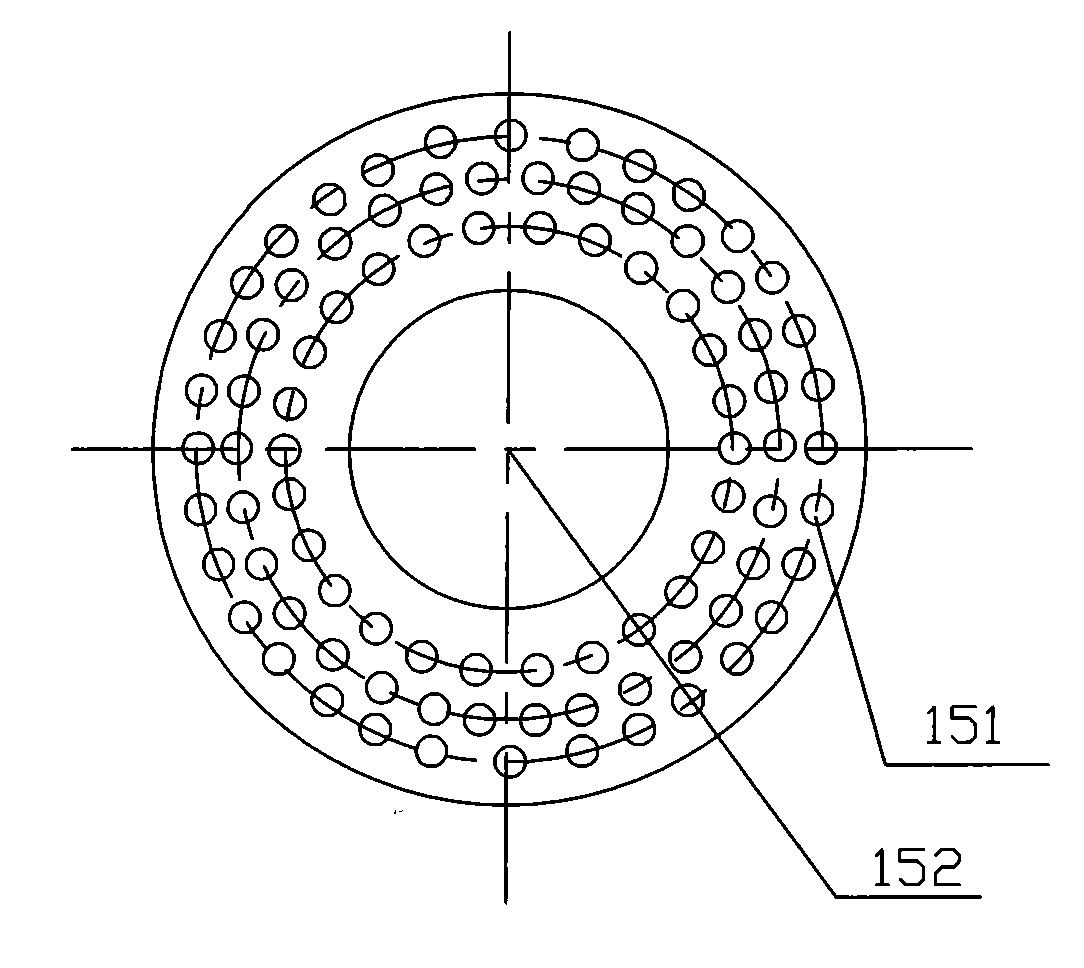

[0038] The secondary air duct 13 is an annular air duct located at the top of the combustion device, and is connected tangentially to the secondary air duct 1 through the secondary air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com