Ethane copolymer and preparation method and application thereof

A technology of ethylene copolymers and complexes, which is used in the production of peroxide cross-linked polyethylene pipes, the manufacture of ethylene copolymers, and the production of peroxide cross-linked polyethylene pipes. The effect of easy tuning and long oxidative induction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

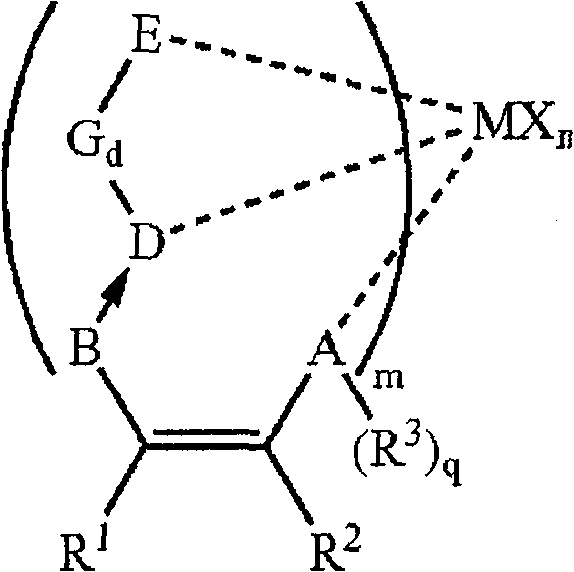

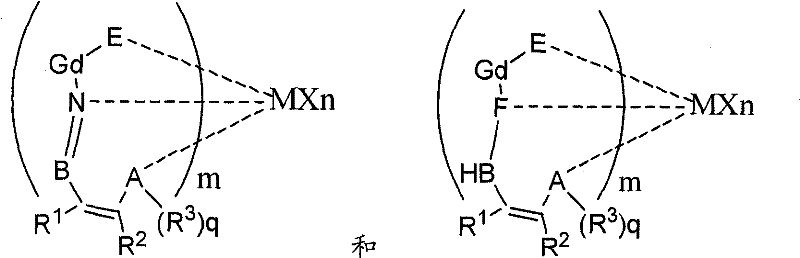

Method used

Image

Examples

preparation example Construction

[0061] In the preparation step of the magnesium compound solution, the alcohol may be selected from one or more of aliphatic alcohol, aromatic alcohol and alicyclic alcohol, and the alcohol may optionally be selected from an alkyl group, a halogen atom and an alkane Oxygen groups are substituted, among which fatty alcohols are preferred. For example, fatty alcohols such as methanol, ethanol, propanol, 2-propanol, butanol, pentanol, 2-methylpentanol, 2-ethylpentanol, 2-hexylbutanol, hexanol, and 2-ethylpentanol Hexanol, etc., among which ethanol, butanol and 2-ethylhexanol are preferred; Aromatic alcohols such as benzyl alcohol, phenethyl alcohol and methyl benzyl alcohol, etc., among which phenethyl alcohol is preferred; Cyclic alcohols such as cyclohexanol, cyclopentanol and cyclooctyl Alcohols and the like, among which cyclohexanol is preferred; alkyl-substituted alcohols such as methylcyclopentanol, ethylcyclopentanol, propylcyclopentanol, methylcyclohexanol, ethylcyclohexa...

Embodiment 1

[0281] Embodiment 1 (preparation embodiment of supported type non-metallocene catalyst)

Embodiment 1-1

[0283] The porous carrier adopts silica gel, the magnesium compound adopts anhydrous magnesium chloride, the alcohol adopts ethanol, and the chemical treatment agent adopts titanium tetrachloride.

[0284] The silica gel was continuously calcined at 600° C. under a nitrogen atmosphere for 4 hours to be thermally activated.

[0285] Weigh 5g of anhydrous magnesium chloride, add 15ml of tetrahydrofuran and 12.5ml of absolute ethanol, heat to 60°C until completely dissolved, add 10g of heat-activated silica gel while it is hot, stir evenly, and after standing for 12 hours, heat evenly to 90°C Vacuum dried to obtain 18.5 g composite carrier.

[0286] Weigh 8g of composite carrier, add 76ml of hexane, add 4.0ml of titanium tetrachloride dropwise over 30 minutes under stirring conditions, stir and react at 60°C for 4 hours, filter, wash with hexane twice, and use 60ml of hexane each time , and vacuum-dried at 25°C to obtain a modified composite carrier.

[0287] Weigh 0.75g struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

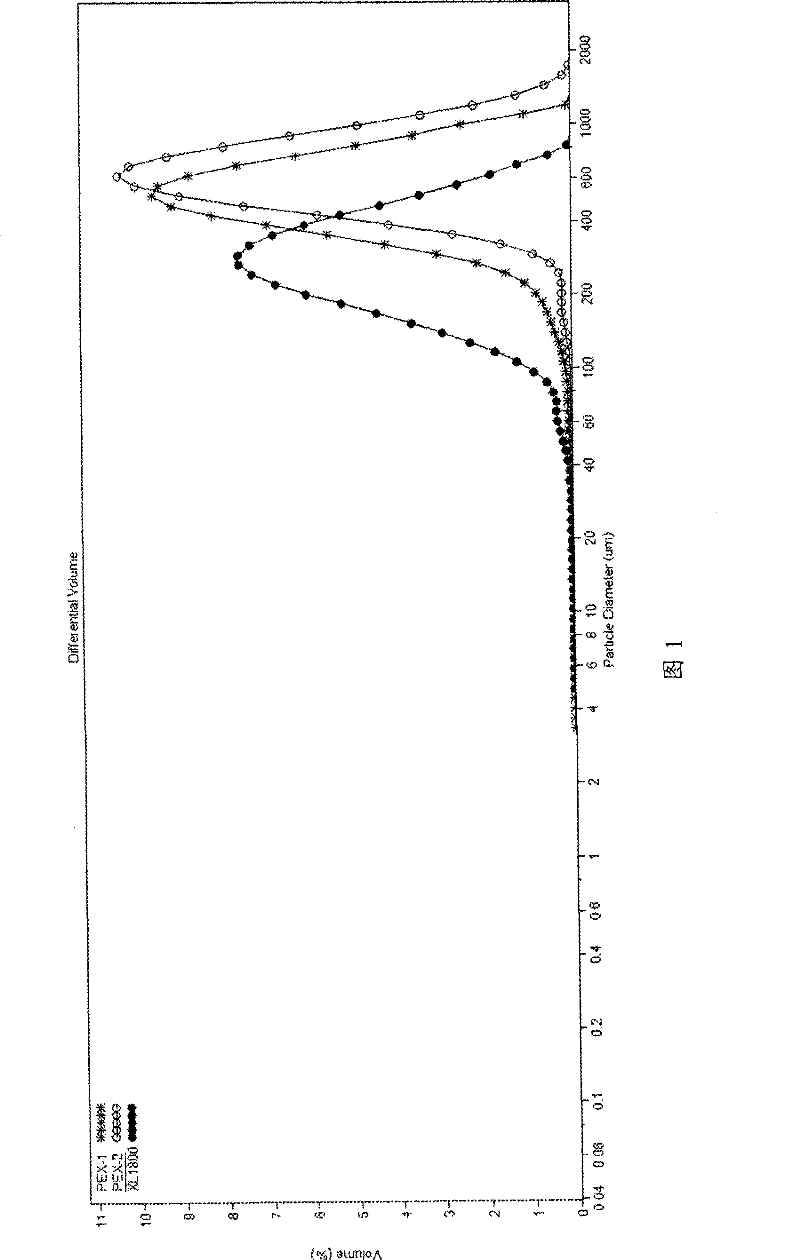

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com