Binder for secondary battery electrode, secondary battery electrode, and secondary battery

A secondary battery and adhesive technology, which is applied in the direction of battery electrodes, non-aqueous electrolyte battery electrodes, active material electrodes, etc., can solve the problems of hindering battery reaction, battery capacity, cycle characteristics and speed characteristics, and achieve heat reduction , internal resistance reduction, and the effect of improving adhesion persistence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

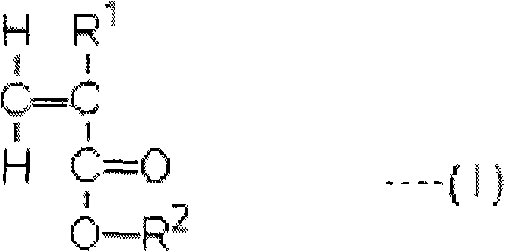

Method used

Image

Examples

Embodiment 1

[0130] 200 parts of toluene, 0.1 part of 2,2'-azobisisobutyronitrile, 40 parts of 2-(perfluorotetradecyl)ethyl acrylate (acrylic acid 2- (Pa-fulorotetrado desil) Echel), 60 parts of 2-ethylhexyl acrylate, nitrogen substitution was sufficiently carried out, and then heated at 80°C to start polymerization. After 5 hours, the reaction was terminated by cooling to obtain a toluene solution of the polymer. The weight average molecular weight of the above polymer was 120,000.

[0131] The above polymer solution was mixed with 3 times the weight of N-methylpyrrolidone, and the toluene was evaporated with an evaporator to obtain an N-methylpyrrolidone solution of the polymer. Using this polymer solution, an electrode paste and a battery were fabricated as described above. The evaluation results are shown in Table 1.

Embodiment 2

[0133] Use 10 parts of 2-(perfluorooctyl)ethyl acrylate instead of 2-(perfluorotetradecyl)ethyl acrylate, use 90 parts of butyl acrylate instead of 2-ethylhexyl acrylate, in addition to Polymerization was carried out under the same conditions as in Example 1 to obtain a toluene solution of the polymer. In addition, the weight average molecular weight of the said polymer was 200,000. Using the above polymer solution, the same experiment as in Example 1 was carried out. The results are shown in Table 1.

Embodiment 3

[0135] Use 10 parts of 2-(perfluorohexyl)ethyl acrylate instead of 2-(perfluorotetradecyl)ethyl acrylate, use 90 parts of 2-ethylhexyl acrylate instead of 60 parts of 2-ethylhexyl acrylate, except Otherwise, polymerization was carried out under the same conditions as in Example 1 to obtain a toluene solution of a polymer. In addition, the weight average molecular weight of the obtained polymer was 200,000. Using the polymer solution, the same experiment as in Example 1 was performed. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com