Enzyme bioelectrochemical sensing chip and preparation method thereof

A bioelectrochemical and sensor chip technology, applied in the field of enzyme bioelectrochemical sensor chip, the preparation of the biosensor chip, can solve the problems of increasing the difficulty and cost of biosensor chip manufacturing, and achieve rapid electron transfer, Improve detection sensitivity and good interception effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

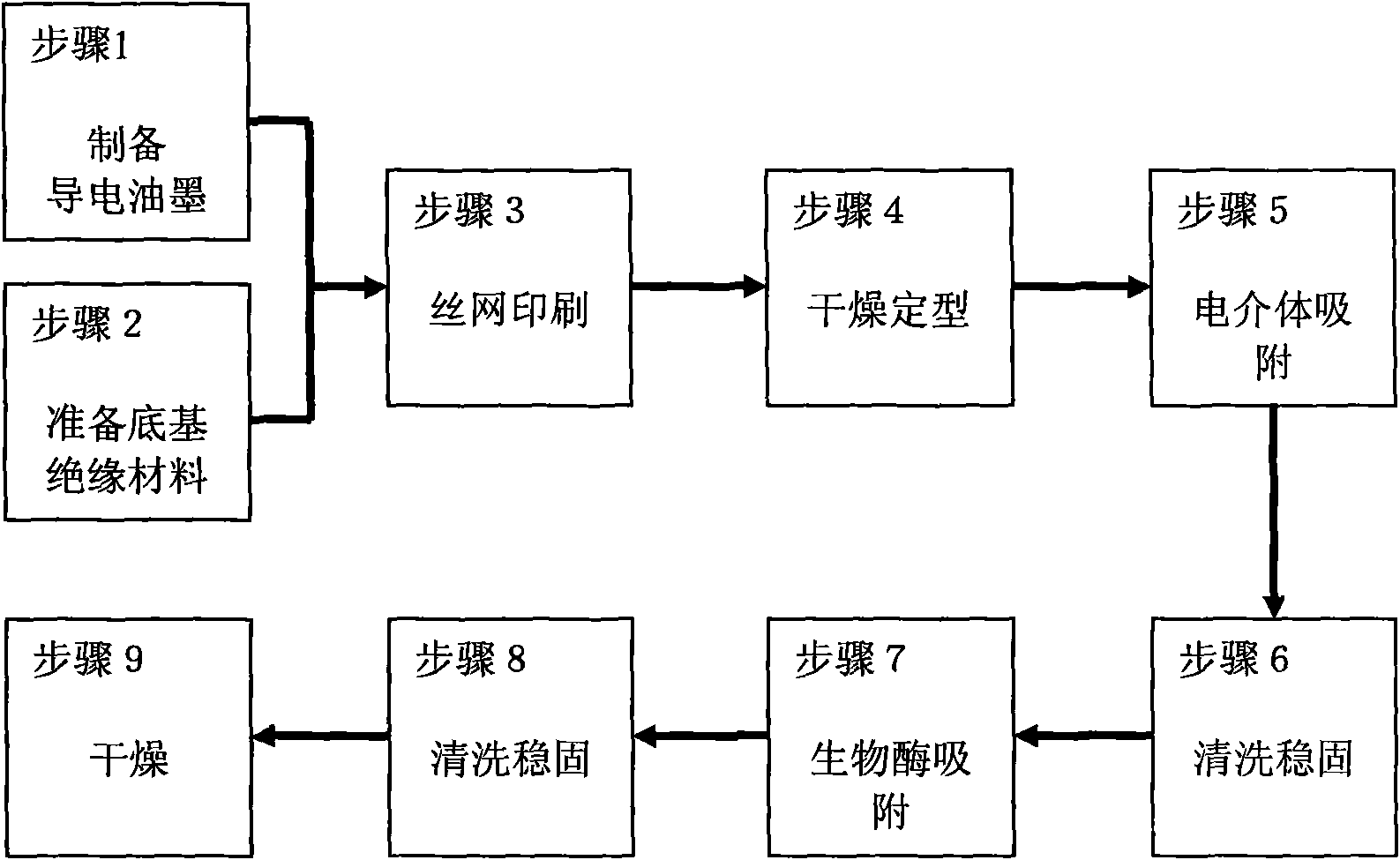

Method used

Image

Examples

Embodiment 1

[0067] Example 1 Preparation of Micro / Nano Porous Biosensor Chip Working Electrode 1

[0068] The conductive ink used in this embodiment is carbon ink. The formula and ratio of carbon ink are listed in Table 1.

[0069] Table 1

[0070] Material

weight percentage

Carboxyl-containing linear polymer A (hydrolyzed styrene and horse

Anhydride-based copolymer) 35%-45% aqueous solution

45-65

carbon black particles

10-15

Graphite particles

15-20

Tween80 (Tween 80) dispersant

2-10

water

0-10

[0071] The carbon ink prepared according to the formula and ratio in Table 1 was screen printed and dried to form a micro-nano porous conductive layer attached to the surface of the polyester base insulating sheet. Its thickness is 5-50 microns. The drying temperature and time are 55-125° C. and 5-30 minutes, respectively.

[0072] The polymer dielectric is obtained by reacting vinylferrocene carbox...

Embodiment 2

[0075] Example 2 Testing of Working Electrode 1 of Micro / Nano Porous Biosensor Chip

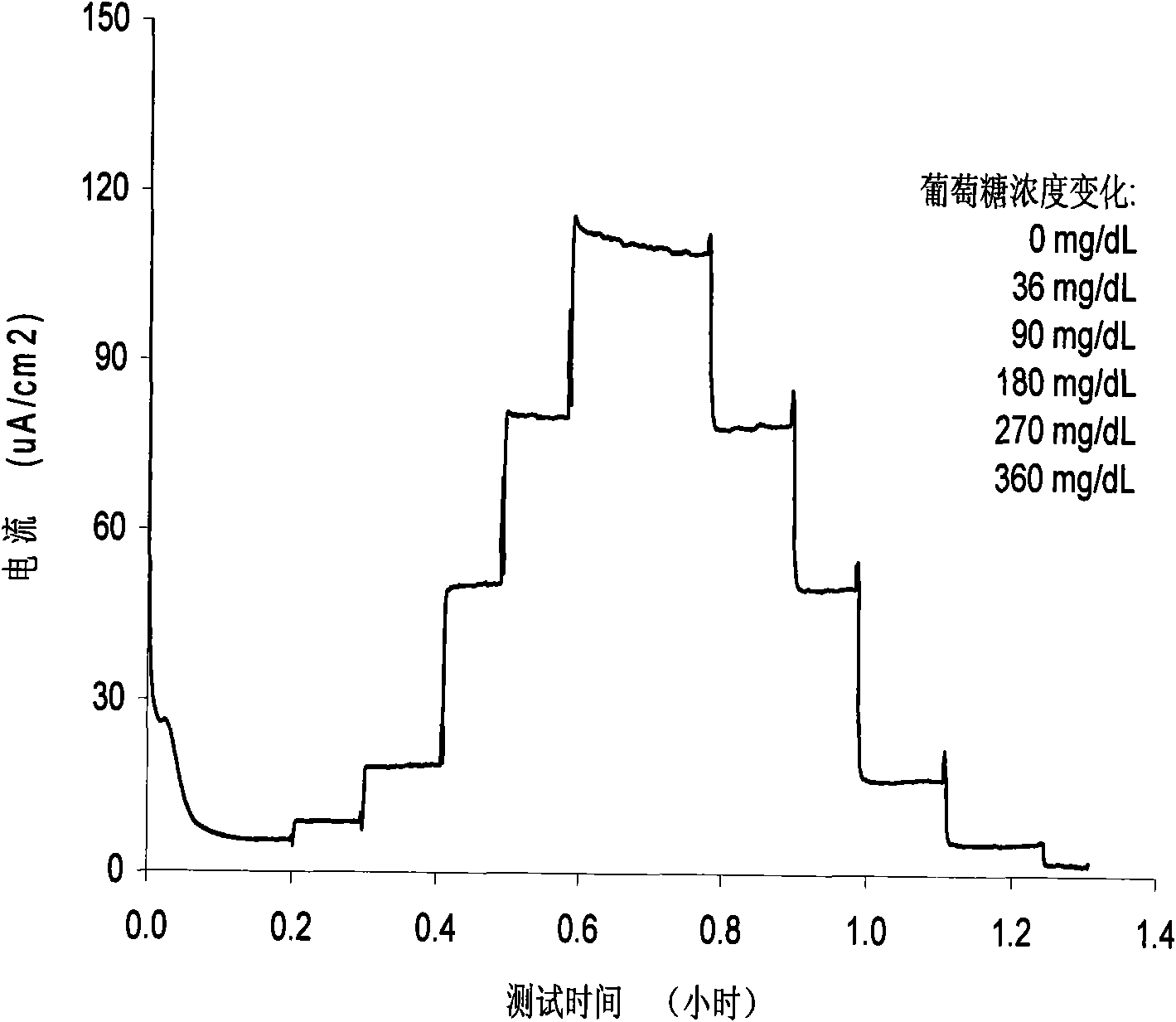

[0076] The biosensor chip was composed of the working electrode 1 of the biosensor chip prepared in Example 1 and an Ag / AgCl reference electrode prepared by screen printing. The test of the glucose response current is to use a stabilized potentiometer connected with a computer to maintain a stable potential of 0.4 volts. The two electrodes are fixed side by side in a small flow cell with an inlet and outlet. PBS with different glucose concentrations (pH 7.4) continuously flows over the surfaces of the two electrodes at a flow rate of 10-15 cm / min, and continuously records the changes of the biosensor chip to glucose and its concentration. The glucose concentration was regularly calibrated with YSI (YSI company, YellowSprings blood glucose analyzer).

[0077] image 3 Display test results: the response current of the sensor chip varies with the concentration of glucose in PBS.

Embodiment 3

[0078] Example 3 Preparation of Micro / Nano Porous Biosensor Chip Working Electrode 2

[0079] Except for the materials used, the preparation process and method of the working electrode 2 of the micro-nano porous biosensor chip are the same as those in Example 1.

[0080] The polymer dielectric here is composed of ethylene ferrocene (vinylferrocene), methacrylic acid-2-diethylamine ethyl ester (2-(diethylammonia)ethyl methacrylate) and methacrylic acid-2-hydroxyethyl ester (2-(hydroxyethyl)methacrylate) is formed by free radical copolymerization. See reference 12 of this patent for details. The biological enzyme is glucose dehydrogenase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com