Applique antibacterial ceramic cutter

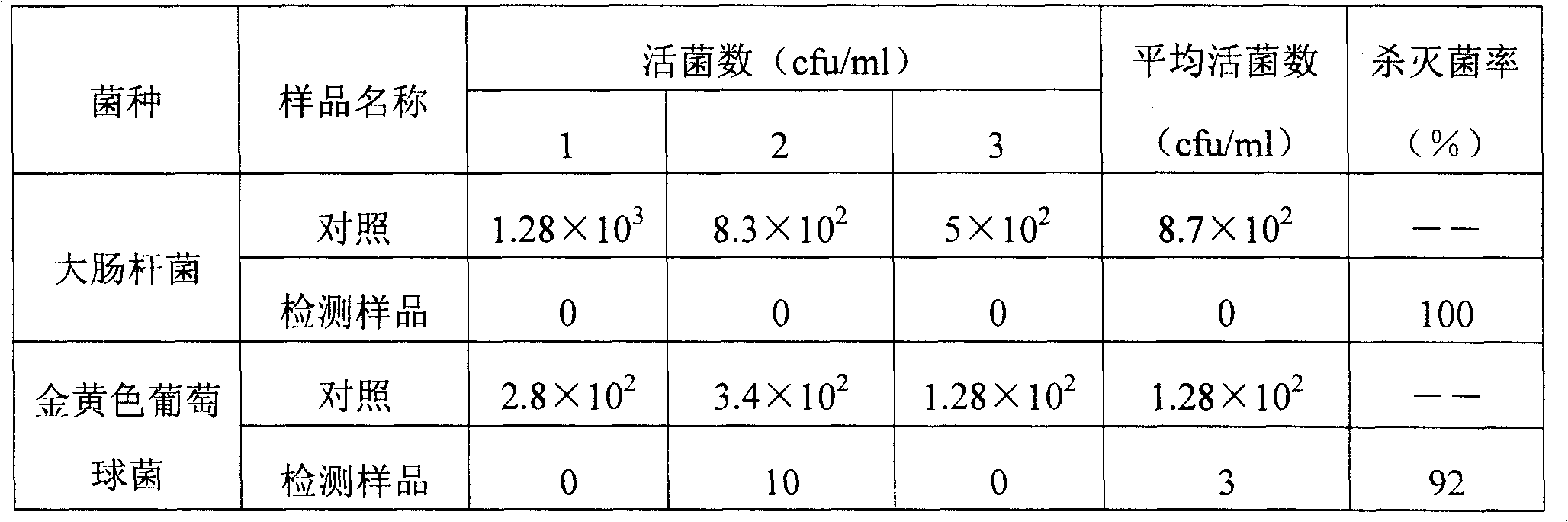

A technology of antibacterial ceramics and knives, applied in the field of decal antibacterial ceramic tableware and its manufacturing method, can solve problems affecting safety, precious metal silver, discoloration, etc., and achieve easy identification and excellent antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0036] Embodiment 1-4: Antibacterial self-cleaning ceramic glaze is formulated according to the method of prior art by the raw material of following percentage by weight: unit: Kg

[0037] Example 1

Example 2

Example 3

Example 4

20

15

15

15

20

20

40

20

14

10

15

10

6

10

6

6

barium carbonate

3

7

3

3

[0038] Sodium carbonate

2

5

2

2

4

5

4

4

3

0

0

6

Zinc oxide

20

10

10

20

Titanium oxide

0

1

0

2

strontium carbonate

2

5

1

1

lithium carbonate

1

2

0

4

cooked talc

1

3

2

1

Aluminum oxide ...

Embodiment 5

[0041] Embodiment 5: preparation method (isostatic pressing molding)

[0042] 1) Selection of raw materials: the tool base material is selected from ultrafine zirconia powder, and the antibacterial glaze is selected from any one of the ingredients in Examples 1-4;

[0043] 2) Abrasives: Add appropriate amount of water to the superfine zirconia powder, wet fine grinding for 1-2 hours, and spray granulation;

[0044] 3) Forming and drying: isostatic pressing at 150-200 MPa, drying under natural conditions or forced drying with circulating hot air;

[0045] 4) Applying floral glaze: According to the tips of the existing technology, silk screen printing and other methods can be used to apply floral glaze, and the design and color can be carried out according to the requirements of customers or printed with the manufacturer's logo;

[0046] 5) Firing: the high temperature of the firing is 1100-1200°C;

[0047] 8) Post-processing.

Embodiment 6

[0048] Embodiment 6: preparation method (grouting molding)

[0049] Prepare mud after abrasives, pressure grouting, multi-stage grouting can also be used for larger cutters, and the others are basically the same as in embodiment 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com