Precise polishing cloth and preparation method thereof

A precision polishing, cloth-based technology, applied in the field of precision polishing cloth, can solve the problems affecting the product yield, scratches on glass substrates, low grinding efficiency, etc., and achieves the effect of satisfying the yield, avoiding scratches and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

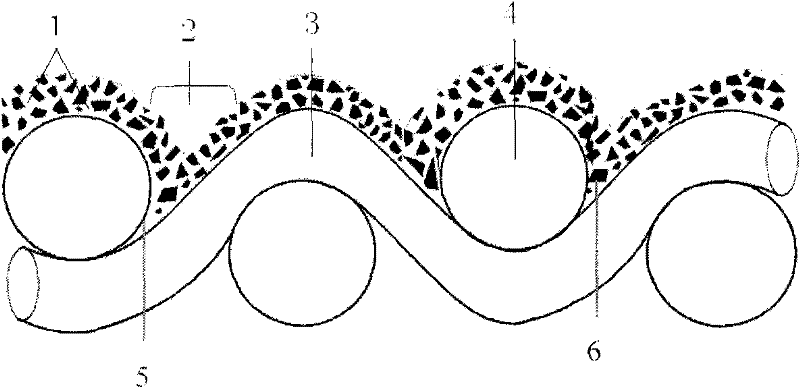

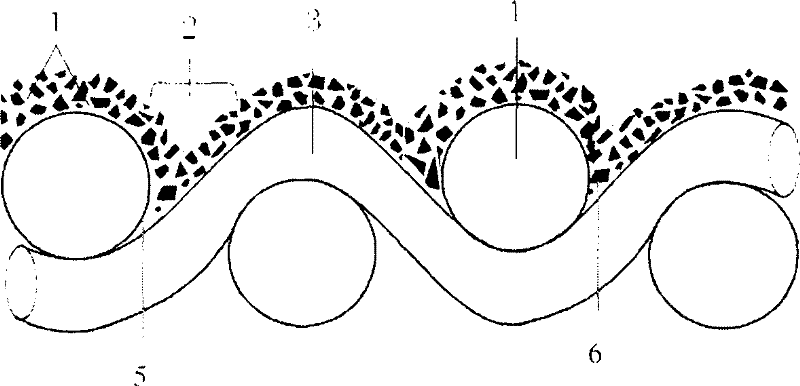

[0021] The preparation method of the precision polishing cloth comprises the following steps: uniformly mixing the abrasive fine powder with an adhesive and a solvent, and then adding a curing agent to prepare an abrasive slurry; coating the abrasive slurry on the surface of the cloth base; and then curing to form an abrasive slurry. coating.

[0022] Among them, the median particle size of the ground powder is 0.1-20 microns; the adhesive refers to: phenolic resin, polyurethane resin, alkyd resin, epoxy resin, acrylate resin, polyvinyl alcohol, carboxymethyl cellulose, urea- One or a mixture of formaldehyde resin, polyether resin, polyester resin; solvent refers to: ethyl acetate, ether, petroleum ether, toluene, methanol, ethanol, isopropanol, butanone, cyclohexanone , chloroform, tetrahydrofuran in one or more of the mixture, in addition to the above-mentioned organic solvents, the solvent can also be water; curing agent refers to polyisocyanate, polyamide, acid anhydride, ...

Embodiment 1

[0024] In the slurry tank, add 200g of alumina micropowder with a median particle size of 6 microns, 4000g of polyester resin with a solid content of 50%, 3000g of mixed solvent (containing ethyl acetate, toluene, butanone), and 20g of antistatic agent in the slurry tank , 20g dispersant, high-speed stirring and dispersing for 10 minutes, then add 5000g polyisocyanate curing agent (Shanghai Xinguang Chemical Factory), stir evenly to prepare abrasive slurry, apply the abrasive slurry on the surface of the cloth base, and cure it at 130°C for 24 Hour.

Embodiment 2

[0026] In the slurry tank, add 200g of alumina micropowder with a median particle size of 6 microns, 3000g of polyester resin with a solid content of 40%, 3000g of mixed solvent (containing ethyl acetate, toluene, butanone), and 30g of antistatic agent in the slurry tank , 30g dispersant, high-speed stirring and dispersing for 10 minutes, then add 4000g polyisocyanate curing agent (Shanghai Xinguang Chemical Factory), stir evenly to prepare grinding slurry, apply the slurry on the surface of the cloth base, and cure at 130°C for 30 hours .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com