SiO2 nanoscale porous material with aerogel property prepared by microwave reaction and preparation method thereof

A porous material, microwave reaction technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of high manufacturing cost and low strength, and achieve the effect of reducing production cost, large specific surface area, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

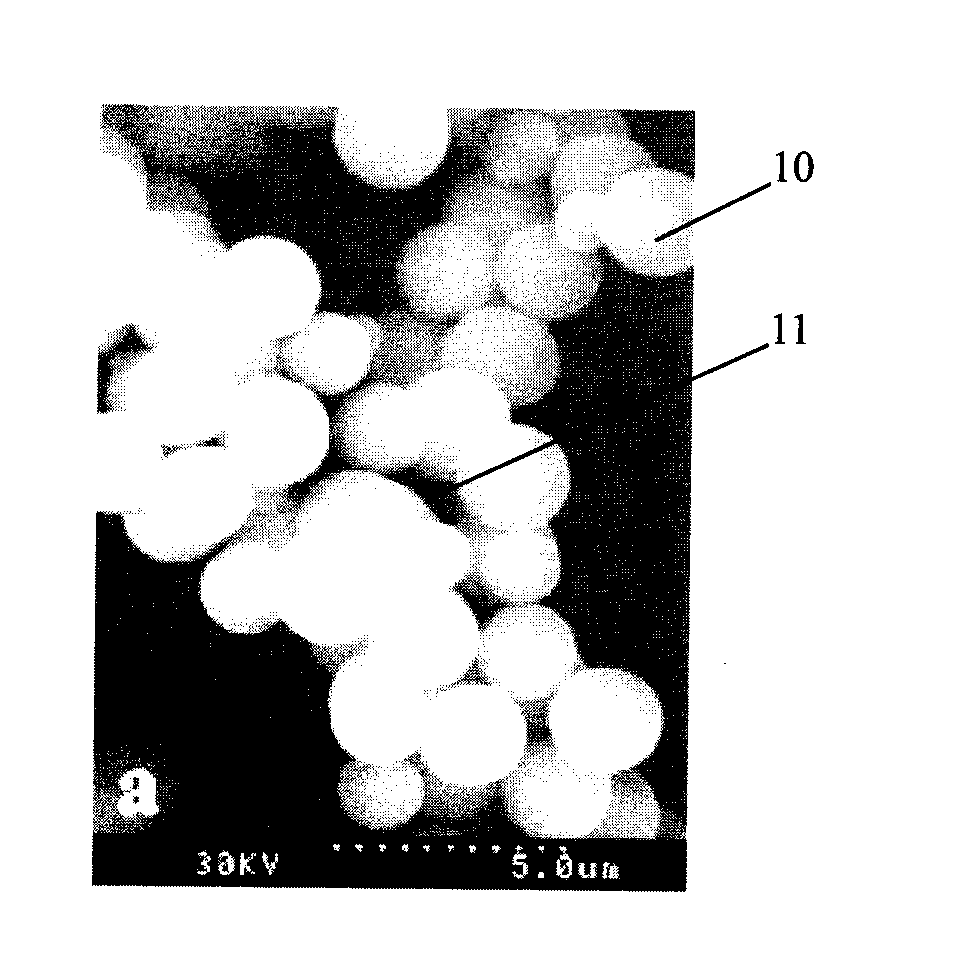

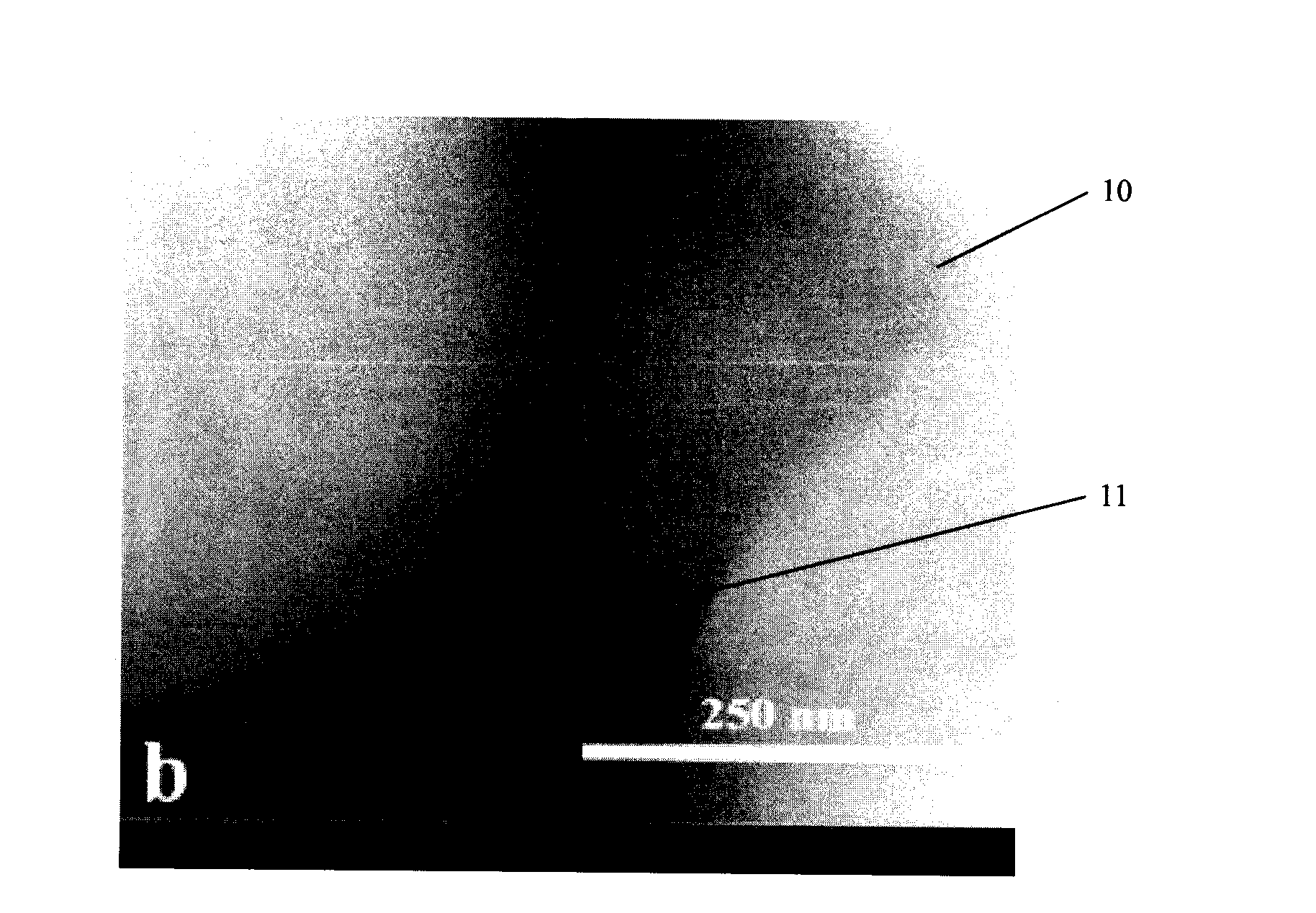

[0038] Example 1: SiO with airgel properties prepared by microwave irradiation of silica sol 2 nanoporous materials

[0039] According to the technical scheme of the present invention, organic siloxane, organic solvent, water, and acid catalyst are used as raw materials to manufacture the microwave-reactive SiO with airgel properties of the present invention. 2 nanoporous materials. in:

[0040] Organosiloxane is selected from: methyl orthosilicate (Tetramethoxysilane), orthosilicate ethyl (Tetraethoxysilane), methyltriethoxysilane (Methyltriethoxysilane), methyltrimethoxysilane (Methyltrimethoxysilane), dimethyldimethoxysilane Dimethyldiethoxysilane, Aminopropyltriethoxysilane, N-octyltriethoxysilane, Polydimethylsiloxane Polydiethoxysilane Oxane (Polydiethoxysiloxane), polyethoxysilane (Polyethoxydisiloxane), perfluoroalkylsiloxane (Perfluoroaklysilane), etc.

[0041] The organic solvent is selected from lower alcohols such as methanol, ethanol, propanol, butanol, or n-h...

Embodiment 2

[0054] Example 2: SiO with airgel properties prepared by synchronous reflection of mixing and microwave irradiation 2 nanoporous materials

[0055] This example is basically the same as Example 1, except that the four components of organosiloxane, organic solvent, water, and acid catalyst are stirred and mixed in a microwave reactor while irradiating with microwaves, and after the reaction The silica sol irradiated by microwave is obtained directly. A base catalyst is added to obtain a silica wet gel. Then aging with absolute ethanol for 24 hours, and drying at normal pressure to obtain a transparent massive solid, that is, the SiO with airgel properties prepared by the microwave reaction of the present invention. 2 nanoporous materials.

[0056] Specifically, tetraethyl orthosilicate, ethanol, and water should be mixed according to a molar ratio of 1:4:4, and an appropriate amount of hydrochloric acid is added to adjust the pH value of the mixed solution to pH = 4.6, and t...

Embodiment 3

[0059] Embodiment 3: Effect of Microwave Irradiation Process on Specific Surface Area

[0060]The technical solution of this embodiment is basically the same as that of Embodiment 1, except that the parameters of the microwave irradiation process are different. The main raw material is Tetraethoxysilane for organosiloxane, ethanol for organic solvent, sulfuric acid for acid catalyst, and distilled water for water. See Table 1 for the specific ratio of "organosiloxane:organic solvent:water" of the components of the ingredients. Add an appropriate amount of sulfuric acid to adjust the pH of the mixture to pH=5. The total volume of the mixed solution is 150ml, and the power of the microwave reactor is set at 300W. The experimental results are shown in Table 1. The results of this experiment show that different microwave irradiation processes have obtained SiO with airgel characteristics prepared by the microwave reaction of the present invention with different specific surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com