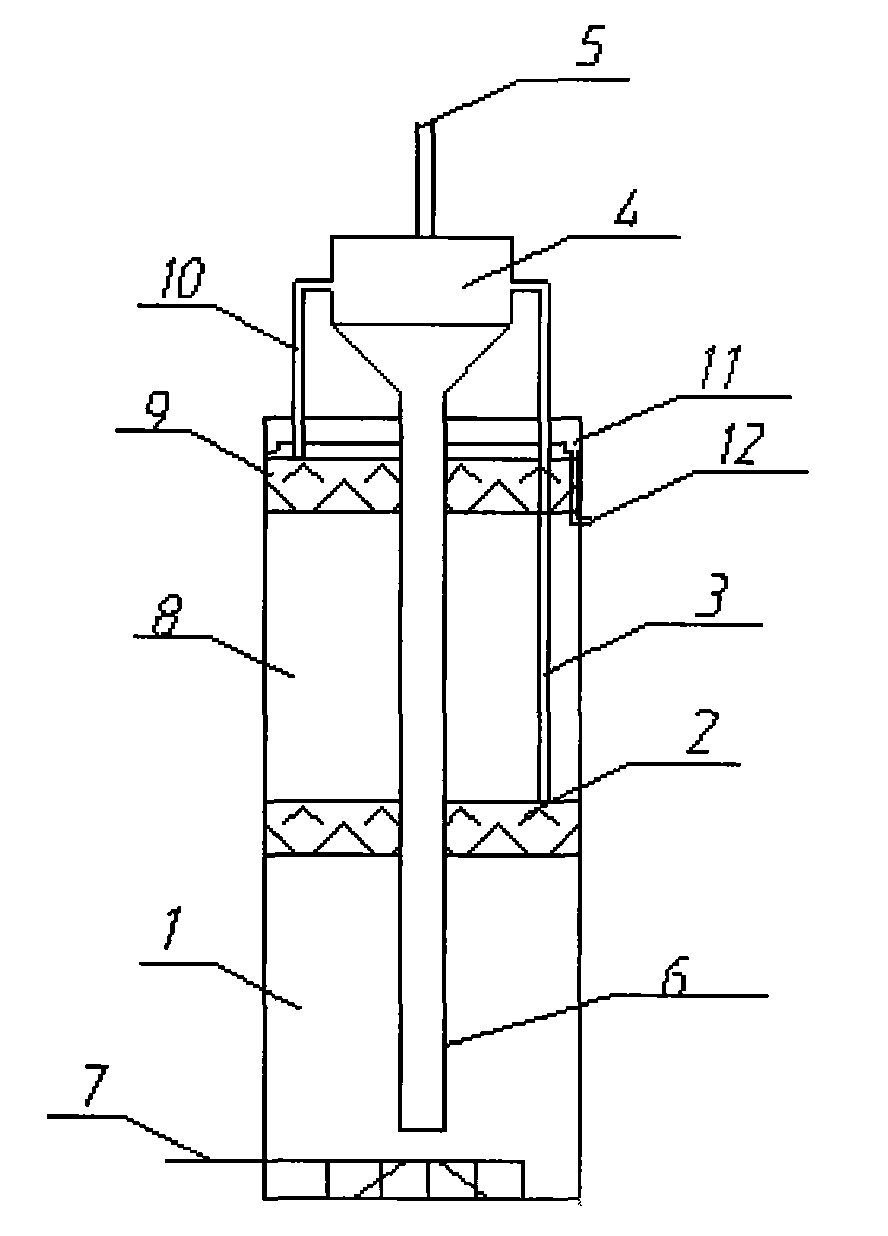

Biogas-lift reinforced anaerobic reactor and application thereof

An anaerobic reactor and anaerobic reaction technology, applied to gas production bioreactors, biochemical instruments, anaerobic digestion, etc., can solve the problems of reduced processing efficiency, deterioration of mass transfer process, small stirring effect, etc., to achieve removal The effect of increasing the efficiency, improving the efficiency of sewage treatment, and saving land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Before the actual operation, the anaerobic reactor should first be inoculated with sludge. The volume of the sludge is about 1 / 2 of the volume of the reactor. Gradually increase the load of the reactor according to the gradient to domesticate the sludge, that is, start the reactor. Control the inlet water temperature at 30°C to 35°C, and the entire start-up process will take about 30 days.

[0024] After the start-up of the reactor, start to feed water continuously, adjust the pH of the feed water to 6.5-8.0, and inject the water into the pretreatment system by the water pump, and then into the anaerobic reactor by the water pump. The circulation flow rate should be determined according to the quality of the effluent water to control the loss of sludge The rate is 10‰, anaerobic fermentation is carried out under the condition of medium temperature (30℃~35℃), the influent COD is about 40000mg / L, the effluent is 5000~6000mg / L, and the COD removal rate of the anaerobic reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com