Thermo-electric converting materials, process for producing the same, and thermo-electric converting element

A technology of thermoelectric conversion materials and manufacturing methods, which is applied in the manufacture/processing of thermoelectric devices, junction lead-out materials of thermoelectric devices, chemical instruments and methods, etc. Use and other issues to achieve the effect of excellent durability, high stability and reliability, and durability without weathering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0225] The silicon residue discharged and generated during the dicing process of the semiconductor assembly of the semiconductor manufacturing company was filtered and separated using a recovery device (manufactured by Sanyo Electric Co., Ltd., Aquacro-Za) and a filter press (manufactured by Parker Engineering Co., Ltd.), and the silicon concentration was obtained. As a result of analysis, the grade (3) silicon residue with a water content of 95% by mass and a water content of 5% by mass was confirmed to contain a B concentration of 100 ppm and a P concentration of 1000 ppm.

[0226] Then, transfer to the dehydration treatment step in the purification and refining step, after throwing the above-mentioned (3) grade silicon residue into a commercially available electric furnace, while supplying argon gas containing 5 vol % hydrogen at a flow rate of 3000 l / min, in the atmosphere The temperature was set at 250° C., and heat treatment was performed for 3 hours to remove moisture. ...

Embodiment 2

[0246] Filter and separate silicon residues discharged and generated during wafer processing (mirror grinding and back grinding processes) at semiconductor manufacturing companies to obtain residues with a silicon concentration of 92% by mass and a moisture content of 8% by mass, and confirm the analysis results , is a grade (2) silicon residue with a B concentration of 6 ppm and a P concentration of 70 ppm.

[0247] A sintered body (undoped) was obtained in the same manner as in Example 1 except that the obtained silicon residue was used and a sintering pressure of 30 MPa was used.

[0248] The obtained sintered body was analyzed in the same manner as in Example 1, and as a result, it contained 90 ppm of Al-derived 2 o 3 Al, 240ppm As, 8ppm P, and 4ppm B are used to make crucibles.

[0249] The density of the obtained sintered body was 99% of the theoretical density.

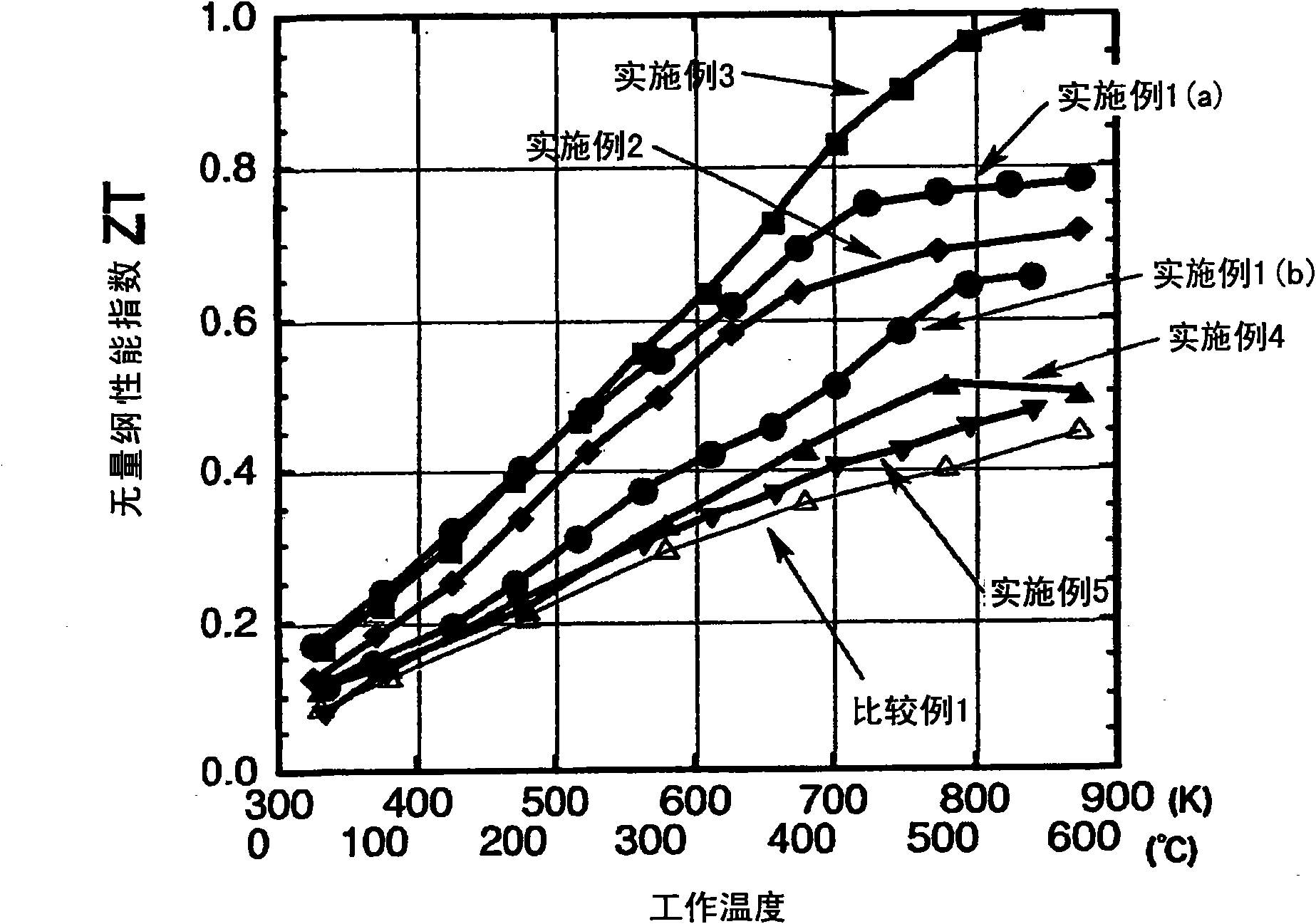

[0250] Using the obtained sintered body, the dimensionless performance index ZT was calculated in the sam...

Embodiment 3

[0253] The silicon residues discharged and generated during wafer processing (mirror grinding and back grinding processes) in semiconductor manufacturing companies were filtered and separated to obtain residues with a silicon concentration of 92% by mass and a water content of 8% by mass. Analysis results It was confirmed that it was a grade (2) silicon residue with a B concentration of 6 ppm and a P concentration of 70 ppm.

[0254] Then, transfer to the dehydration treatment step in the purification step, use a commercially available electric furnace, while supplying argon gas containing 5 volume % hydrogen at 3000 l / min, set the temperature at 250° C. in the atmosphere, and heat-treat the silicon residue for 3 hours, the moisture was removed.

[0255] Thereafter, transfer to the silicon oxide removal step in the purification and refining step, the above-mentioned silicon residue that has been dehydrated is fed in the same above-mentioned electric furnace while supplying arg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com