Thermopile infrared gas detector taking composite film as infrared absorption layer, and processing method of detector

An infrared absorption layer and gas detector technology, which is applied in the manufacture/processing of electrical radiation detectors, thermoelectric devices, and thermoelectric devices that only use the Peltier or Seebeck effect. problem, to achieve the effect of improving heat flux absorption, good flatness, and increasing duty cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

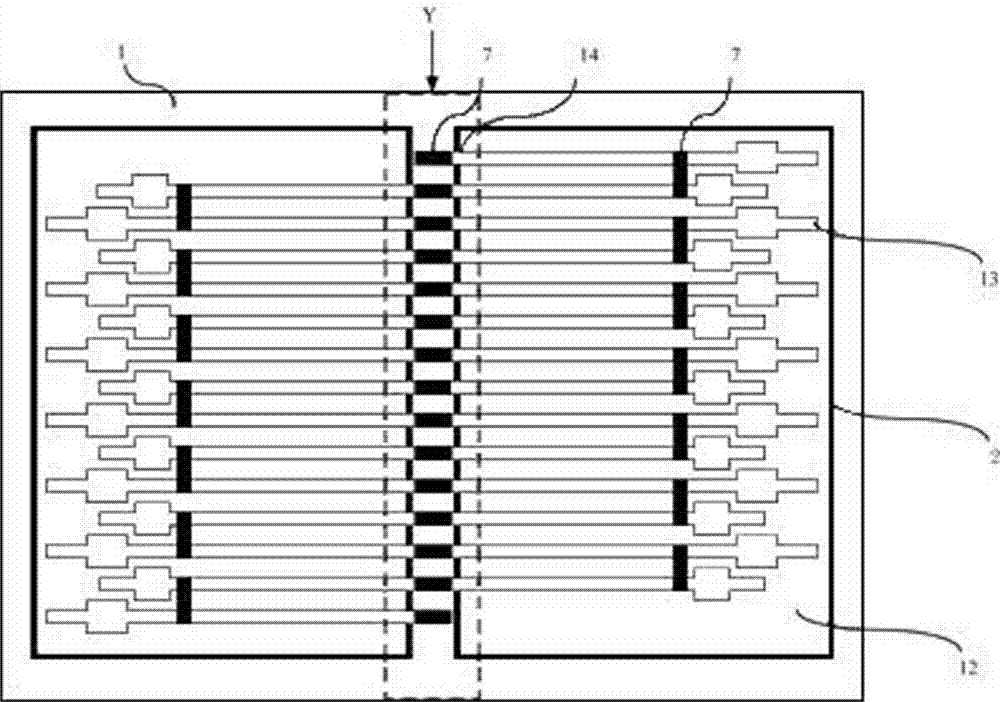

[0053] Embodiment 1: The main process steps include: selecting an SOI substrate as a device base, photoetching a square release hole, forming a closed isolation groove with the substrate, and controlling the range of dry release.

[0054] 1. LPCVD grows 5000? SiO2 as a dielectric support film, and LPCVD TEOS fills the isolation groove.

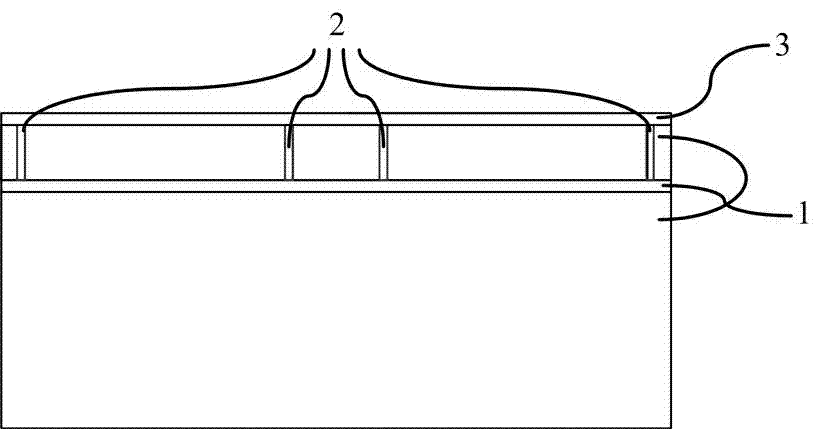

[0055] 2. LPCVD deposited 3000? POLY, ion implanted boron, dose 1.5E16cm-2, energy 50KeV.

[0056] 3. LPCVD deposited 1000? SiO2, LPCVD3000? POLY, ion implanted phosphorus, dose 1.5E16cm-2, energy 50KeV.

[0057] 4. Form the shape of P / N thermocouple strip by photolithography. The width of the thermocouple bar formed by photolithography in the Z-shaped structure is 3um, which can increase the effective heat conduction length and improve the thermoelectric conversion efficiency.

[0058] 5. Etch the top isolation layer of SiO2 by photolithography for 2000 ?, exposing the absorption region, pad and metal connection part.

[0059] 6. Preparati...

Embodiment 2

[0064] Example 2: The specific process steps are similar to Example 1, the main difference is that the junction between the cold end and the hot end of the N / P type thermocouple strip is not etched, and the connection between the cold end and the hot end of the thermocouple strip is made by metal connection. short circuit.

Embodiment 3

[0065] Example 3: The specific process steps are similar to Example 1, the main difference is that before releasing the polyimide, the window is etched on the absorbing layer film, which helps to reduce the release time, improve the release efficiency, and is more conducive to ensuring the suspension of the absorbing layer Film structure and maintaining film flatness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com