Method for preparing pressure sensor with nano SiC thin film

A pressure sensor and nanotechnology, applied in the field of pressure sensor preparation, can solve the problems of inability to obtain large-area uniform nano-SiC films, high temperature resistance of devices, poor radiation resistance, and device application limitations, and achieve high electron emission efficiency and low cost. Low, the effect of increasing stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

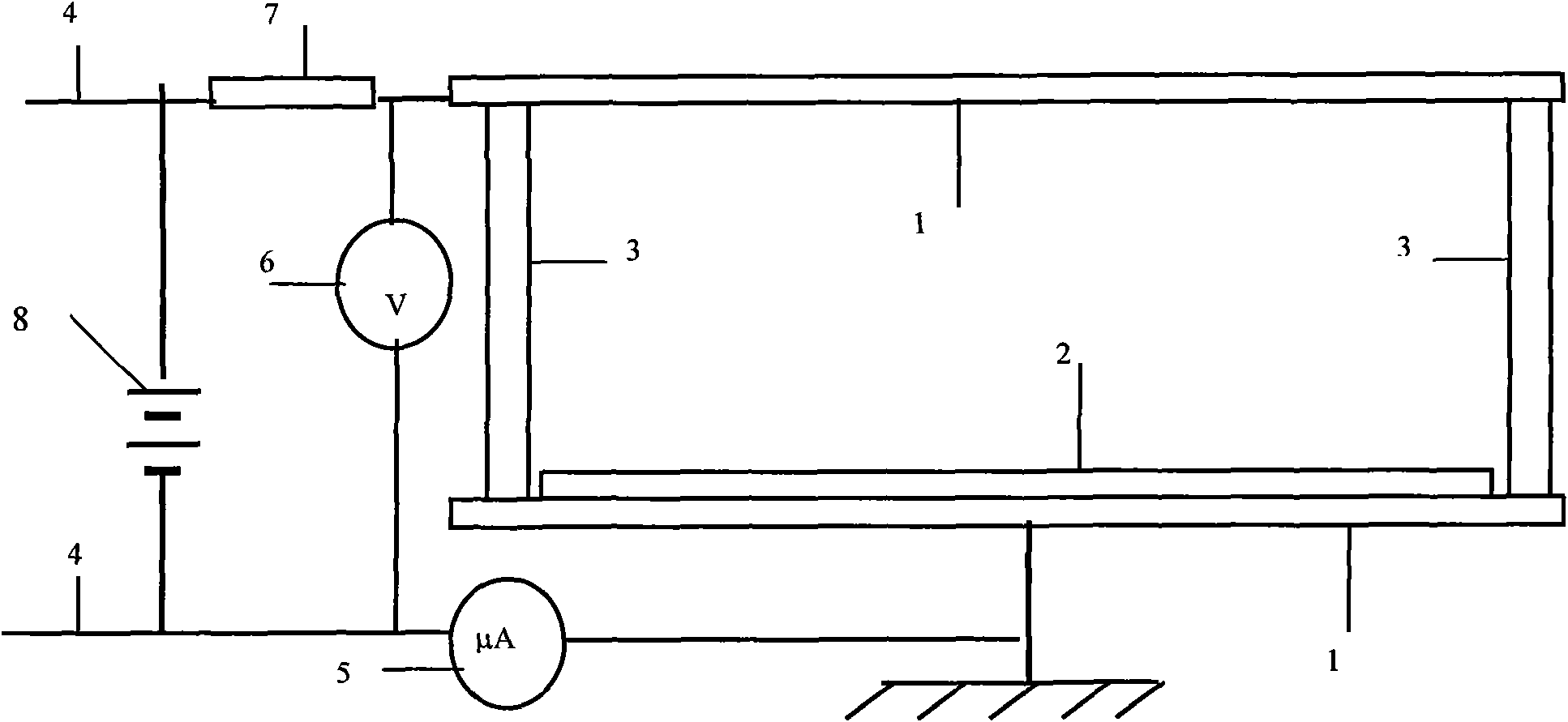

Image

Examples

Embodiment 1

[0027] A method for preparing a pressure sensor with a nano-SiC thin film, comprising the following steps:

[0028] a. Preparation of nano-SiC slurry

[0029] First, grind nano-SiC, nano-graphite, and ethyl cellulose respectively, and disperse their agglomerates, then mix nano-graphite, nano-SiC, and ethyl cellulose in a ratio of 4:7:8 by weight, and fully stir them evenly. Solute: Add the solute to the terpineol solvent at a weight ratio of 1:5, heat to 380K and stir thoroughly, ultrasonically disperse for 3 hours, then pass through a 400-mesh sieve, and finally cool naturally to room temperature to obtain a nano-SiC slurry for use.

[0030] b. Preparation of cathode emitter plate

[0031] First, a 350-mesh metal screen is selected, and the nano-SiC paste is screen-printed on a conductive glass plate (ie, a substrate), and then thermally sintered. During thermal sintering treatment, first raise the temperature to 325K and keep it for 25 minutes, then raise the temperature t...

Embodiment 2

[0038]A method for preparing a pressure sensor with a nano-SiC thin film, comprising the following steps:

[0039] a. Preparation of nano-SiC slurry

[0040] Grind nano-SiC, nano-graphite, and ethyl cellulose separately first, disperse their agglomerates, then mix nano-graphite, nano-SiC, and ethyl cellulose in a ratio of 4:7:8 by weight, stir well and use it as a solute, Add the solute to the terpineol solvent at a weight ratio of 1:6, heat to 370K and stir thoroughly, ultrasonically disperse for 4 hours, then pass through a 450 mesh sieve, and cool the nano-SiC slurry to room temperature naturally for use.

[0041] b. Preparation of cathode emitter plate

[0042] First, a 300-mesh metal screen is selected, and the nano-SiC paste is screen-printed on a copper plate (ie, a substrate), and then thermally sintered. During thermal sintering treatment, first raise the temperature to 325K and keep it for 30 minutes, then raise the temperature to 450K and keep it for 75 minutes, t...

Embodiment 3

[0049] A method for preparing a pressure sensor with a nano-SiC thin film, comprising the following steps:

[0050] a. Preparation of nano-SiC slurry

[0051] First, grind nano-SiC, nano-graphite, and ethyl cellulose respectively, and disperse their agglomerates, then mix nano-graphite, nano-SiC, and ethyl cellulose in a ratio of 4:7:8 by weight, and fully stir them evenly. Solute: Add the solute to the terpineol solvent at a weight ratio of 1:8, heat to 350K and stir thoroughly, ultrasonically disperse for 5 hours, then pass through a 400-mesh sieve, and finally cool naturally to room temperature to obtain a nano-SiC slurry for use.

[0052] b. Preparation of cathode emitter plate

[0053] First, select a 350-mesh polyester screen, screen-print the nano-SiC paste on a conductive glass plate (ie, the substrate), and then perform thermal sintering. During thermal sintering treatment, first raise the temperature to 325K and keep it for 30 minutes, then raise the temperature to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com