Method for preparing needle coke by coal-tar asphalt

A technology of coal tar pitch and needle coke, which is applied in the field of organic compound coal tar pitch to prepare carbon material needle coke, which can solve the problems of unclear mechanism of distillate action, failure to use ultra-high power electrodes, and staying in perceptual knowledge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

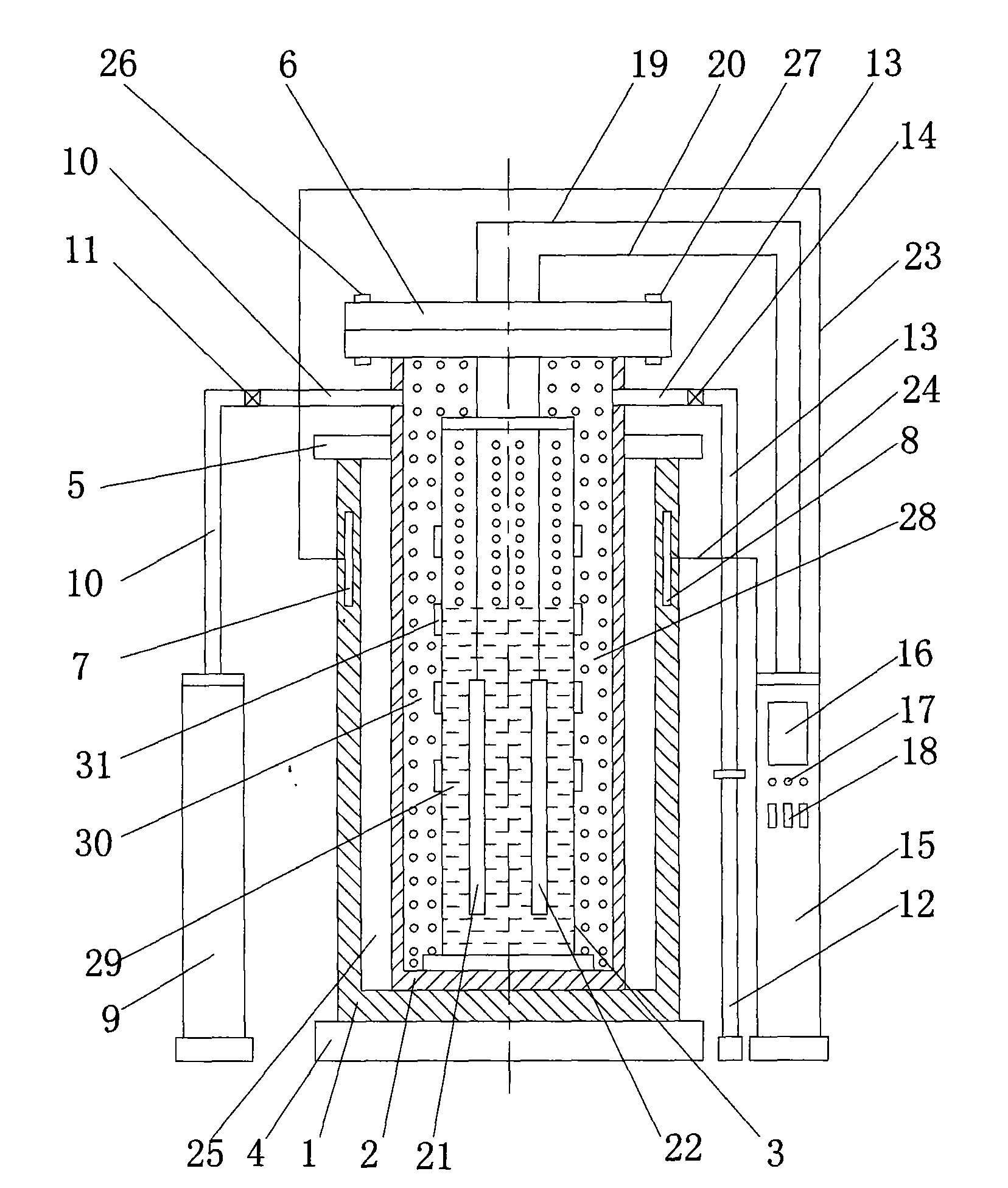

[0069] The present invention will be further described below in conjunction with accompanying drawing:

[0070] figure 1 As shown, it is the state diagram of needle coke induced by magnetic field. A reaction kettle is placed in a high-temperature heating furnace, a glass test tube is placed in the reaction kettle, and a coil made of enamelled copper wire is wound outside the glass test tube. DC power supply connection, the DC power supply voltage is 20V, the current is 11A, the reaction kettle is sealed by a sealing cover, and the vacuum pump is used to extract the vacuum in the reaction kettle, the vacuum degree is 3325Pa, and then the nitrogen gas is input from the nitrogen bottle, and the nitrogen input flow rate is 50cm 3 / min, the pressure value is kept at 3×10 after inputting nitrogen 5 Pa; the coal tar pitch melt is oriented at the bottom of the glass test tube under the action of the magnetic field generated when the coil is energized, thereby forming ordered needle c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com