Preparation method of nickel ferrite based magnetic loaded type titanium dioxide photo-catalyst

A technology of titanium dioxide and photocatalyst, which is applied in the field of preparation of nickel ferrite-based magnetically supported TiO2 photocatalyst powder, can solve the problems of non-dispersible powder, affect photocatalytic efficiency, and weaken recovery ability, and achieve simple and reliable equipment. control, easy scale production, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

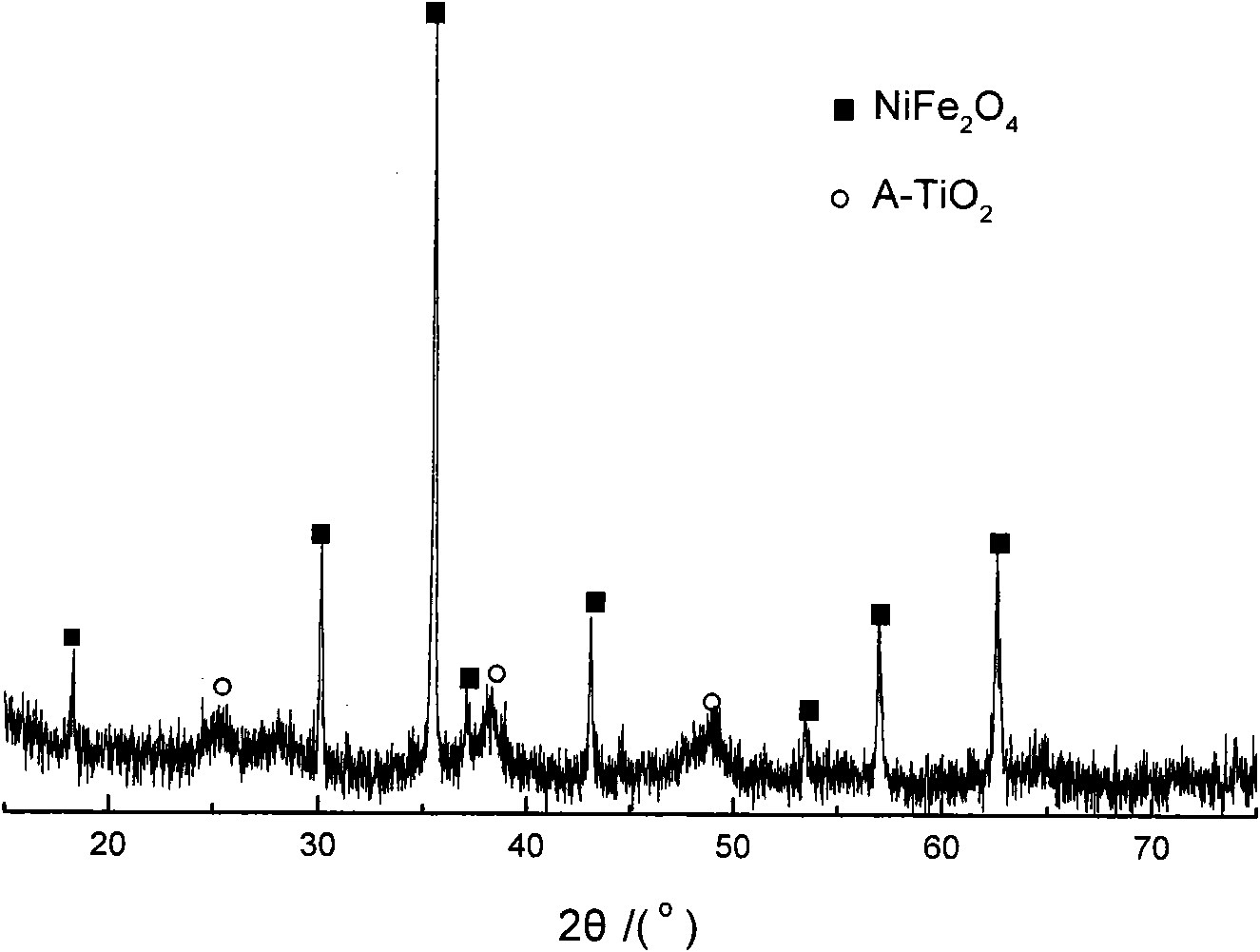

[0024] A preparation method of nickel ferrite-based magnetically supported titanium dioxide photocatalyst, the steps of the preparation process comprising:

[0025] (1) Prepare equal volumes of 0.5-1 mol / liter nickel sulfate solution, 1-2 mol / liter ferrous sulfate solution, and 3 times volume of 0.6-1.2 mol / liter oxalic acid solution. Use concentrated ammonia water to adjust the pH value of the nickel sulfate solution to 7-8, put it into a water bath, stir and heat at 45-55°C. Then quickly pour the oxalic acid solution and the ferrous sulfate solution into the nickel sulfate solution at the same time, and react at a constant temperature for 30 to 60 minutes to obtain a mixture of nickel oxalate and ferrous oxalate. Then the oxalate precipitate was washed and filtered, and dried at 80°C. The dried nickel-iron oxalate mixture is calcined in a muffle furnace at 650-900° C. for 1-2 hours to obtain micron-sized nickel ferrite powder.

[0026] (2) Prepare a nickel ferrite suspensi...

Embodiment 1

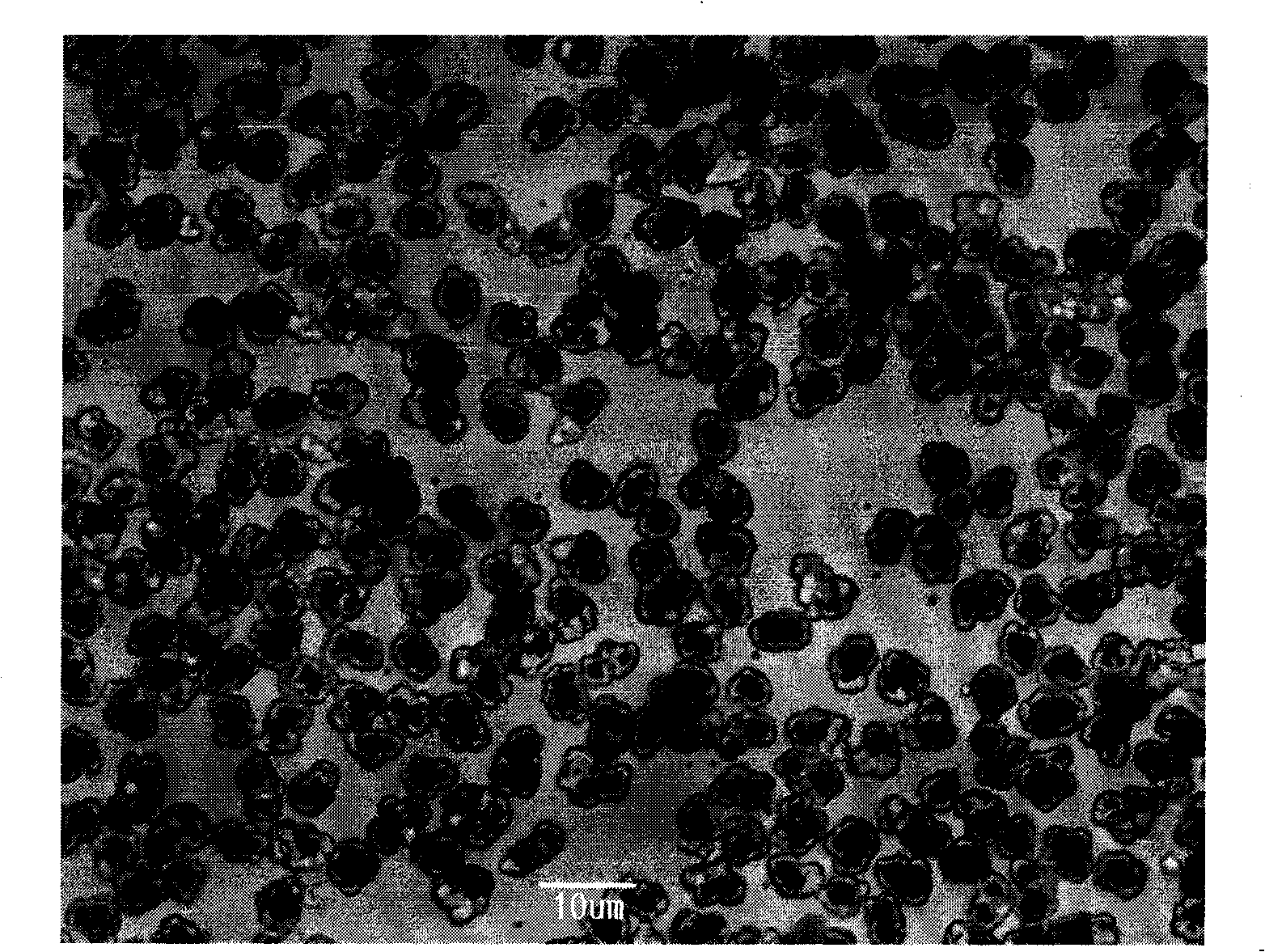

[0029] Nickel Ferrite-based Magnetically Supported Titanium Dioxide Composite Microsphere Photocatalyst with Core / Shell Mass Ratio 1:0.1

[0030] 1. Prepare 1 liter of 0.5 mol / liter nickel sulfate solution, 1 liter of 1 mol / liter ferrous sulfate solution, and 3 liters of 0.6 mol / liter oxalic acid solution. Adjust the pH value of the nickel sulfate solution to 7 with concentrated ammonia water, put it into a water bath, stir and heat at 45°C. Then quickly pour the oxalic acid solution and ferrous sulfate solution into the nickel sulfate solution at the same time, and react at a constant temperature for 60 minutes to obtain a mixture of nickel oxalate and ferrous oxalate. Then the oxalate precipitate was washed and filtered, and dried at 80°C. The dried nickel-iron oxalate mixture is calcined at 650° C. for 2 hours in a muffle furnace to obtain micron-sized nickel ferrite powder.

[0031] 2. Prepare a nickel ferrite suspension with a concentration of 50 grams per liter with de...

Embodiment 2

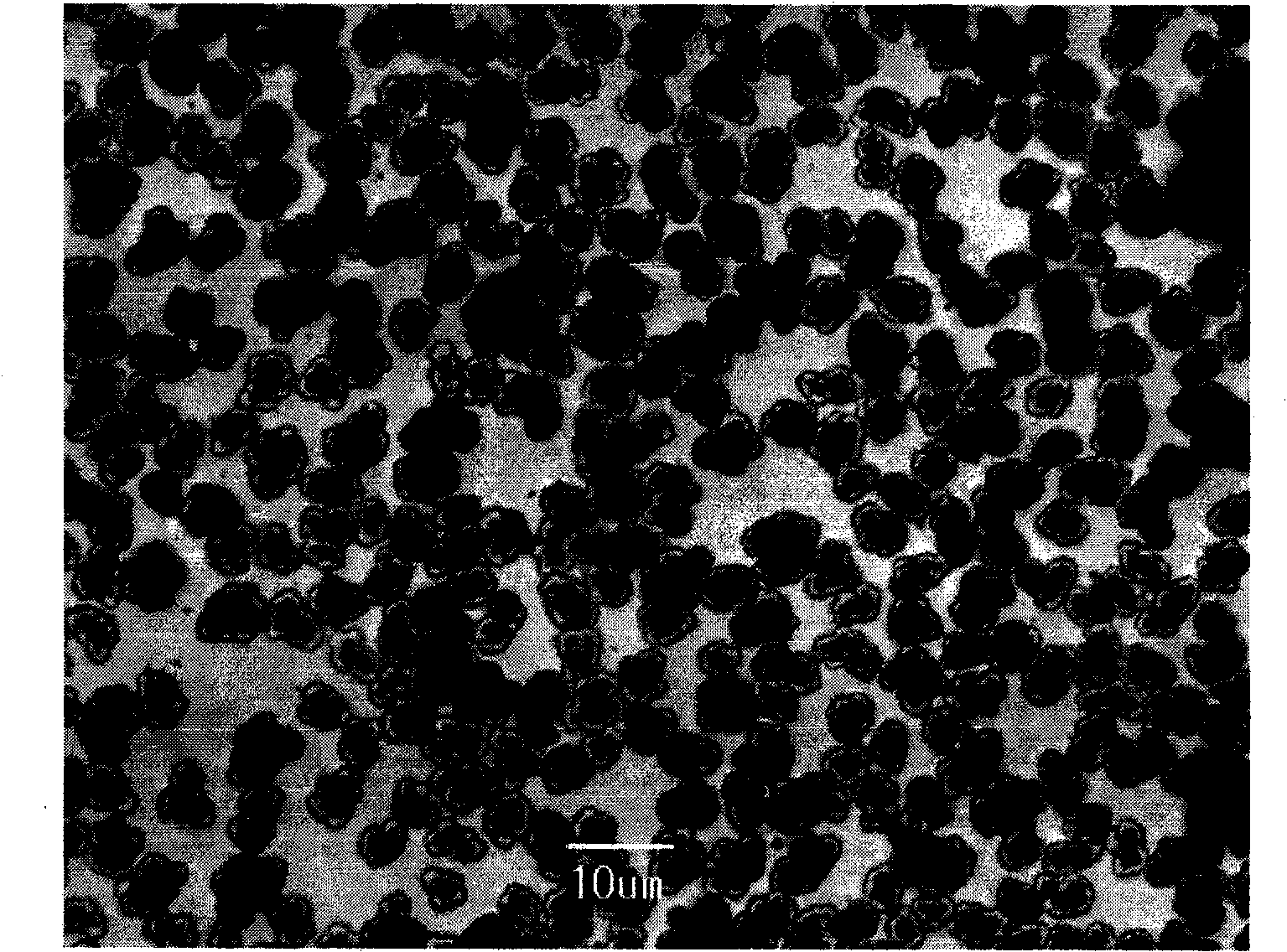

[0034] Nickel Ferrite-based Magnetically Supported Titanium Dioxide Composite Microsphere Photocatalyst with Core / Shell Mass Ratio 1:0.15

[0035] 1. Prepare 1 liter of 0.8 mol / liter nickel sulfate solution, 1 liter of 1.6 mol / liter ferrous sulfate solution, and 3 liters of 0.96 mol / liter oxalic acid solution. Adjust the pH value of the nickel sulfate solution to 7.5 with concentrated ammonia water, put it into a water bath, stir and heat at 55°C. Then quickly pour the oxalic acid solution and the ferrous sulfate solution into the nickel sulfate solution at the same time, and react at a constant temperature for 30 minutes to obtain a mixture of nickel oxalate and ferrous oxalate. Then the oxalate precipitate was washed and filtered, and dried at 80°C. The dried nickel-iron oxalate mixture is calcined in a muffle furnace at 900° C. for 1 hour to obtain micron-sized nickel ferrite powder.

[0036] 2. Prepare a nickel ferrite suspension with a concentration of 100 grams per lit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com