Preparation method of ferrite magnetic film

A magnetic thin film and ferrite technology, which is applied in the field of preparation of spinel ferrite thin film, can solve the problems of Curie temperature and magnetocrystalline anisotropy constant reduction, consumption of too much reaction solution, low resonance frequency, etc. , to achieve the effect of simple preparation method, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1. Preparation of active substrate

[0017] Cut the glass into a substrate with a size of 12mm×24mm×0.5mm, and plate Ag on the glass substrate as follows:

[0018] a. Ultrasonic cleaning the glass substrate in distilled water, alcohol, and acetone solutions to remove impurities and oil stains on the surface;

[0019] b. Immerse the cleaned substrate into 5-10g / l SnCl at room temperature 2 In the sensitizing solution mixed with 0.08M hydrochloric acid, soak for 0.5 to 5 minutes;

[0020] c. After taking it out, immerse it in distilled water for about 2 to 20 seconds;

[0021] d. Then take it out, and then immerse the glass substrate in 1-10g / l normal temperature AgNO 3 In the activated water solution, soak for 1 to 6 minutes;

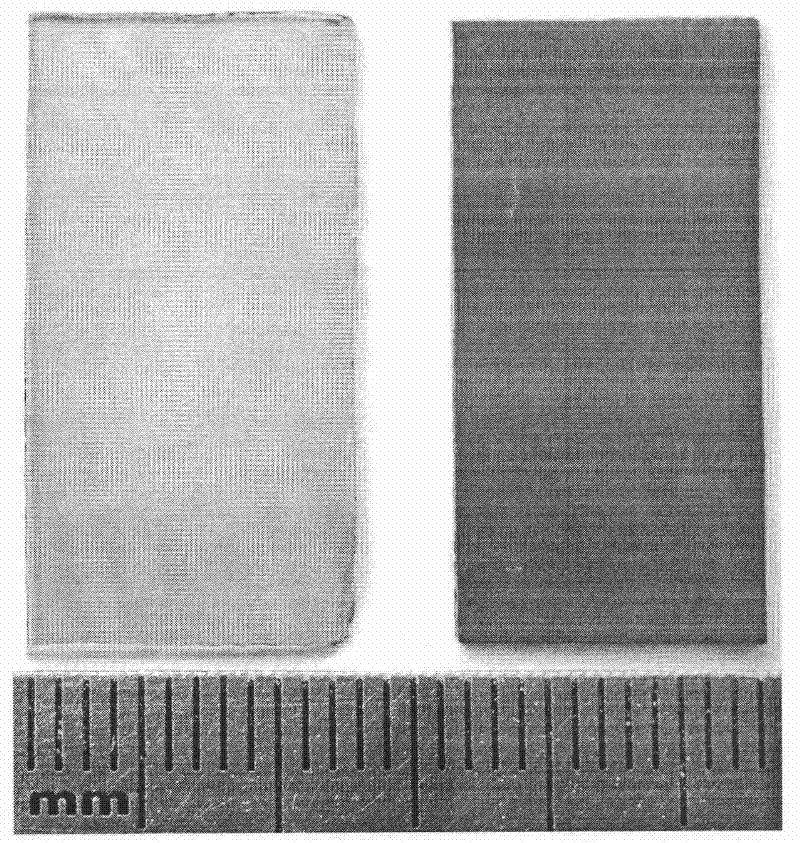

[0022] e. Repeat steps b-d several times until the glass substrate material changes from bright and transparent to brown, indicating that the activation is successful.

[0023] It should be noted that: (1) when configuring the sensitizing sol...

Embodiment 2

[0027] The preparation of the Ag-coated glass substrate was the same as in Example 1.

[0028] Configured with 15mM Fe(NO 3 ) 3 , 0.4mM Zn(NO 3 ) 2 Mix 50ml of the solution with 30mM DMAB, place it in a water bath at 80°C, and react for 1 hour to form a component of Zn 0.41 Fe 2.59 o 4 ferrite film. This thin film had a coercive force of 45 Oe and a saturation magnetization of 447 emu / cc.

[0029] Near this composition point, the film has the maximum saturation magnetization, regardless of the increase or decrease of Zn content, the saturation magnetization will decrease, but the coercive force will only gradually decrease with the increase of Zn content.

Embodiment 3

[0031]The preparation of the Ag-coated glass substrate was the same as in Example 1.

[0032] Configured with 10mM Fe(NO 3 ) 3 , 0.8mM Co(NO 3 ) 2 Mix 50ml of solution with 30mM DMAB, put it in a water bath at 80°C, and react for 1 hour to produce a hard ferrite film with a coercive force of 443Oe.

[0033] Strongly anisotropic Co 2+ The addition of ions can rapidly increase the coercive force of the ferrite film, and the film transitions from a soft magnetic material to a hard magnetic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com