La1-xNdxFeO3 nanocrystalline material and preparation method thereof

A nanocrystalline material, 3·nh2o technology, used in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of insufficient powder, limited application of perovskite composite oxides, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

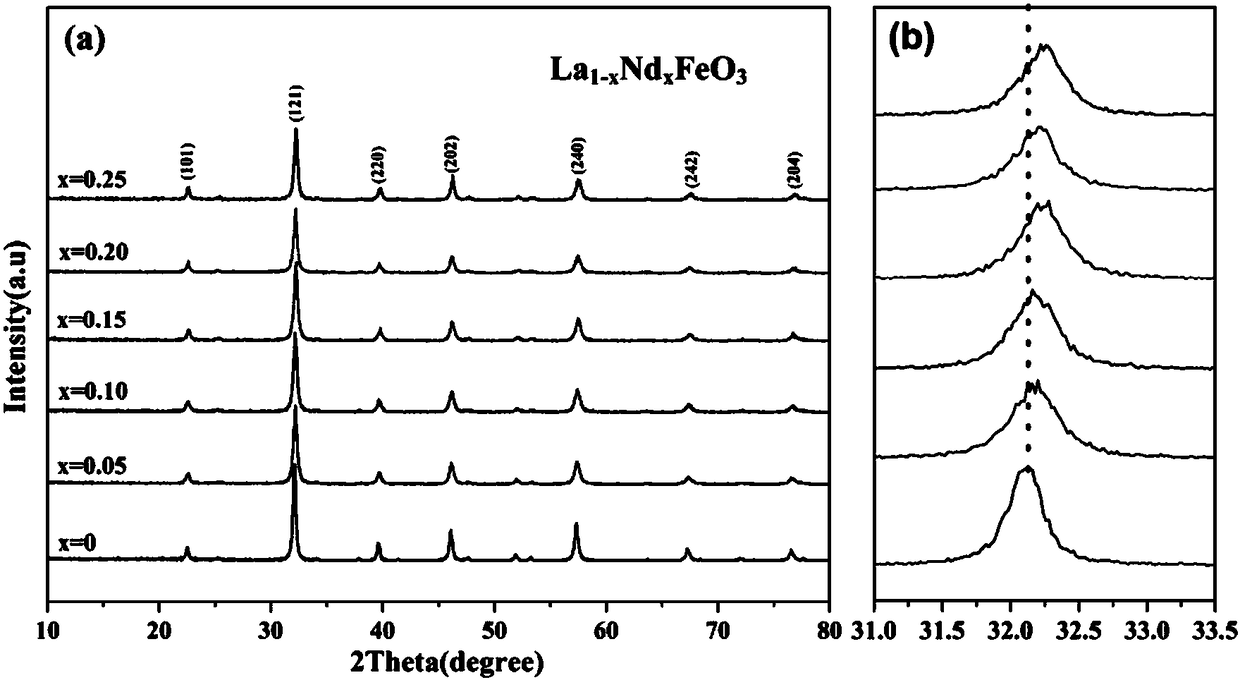

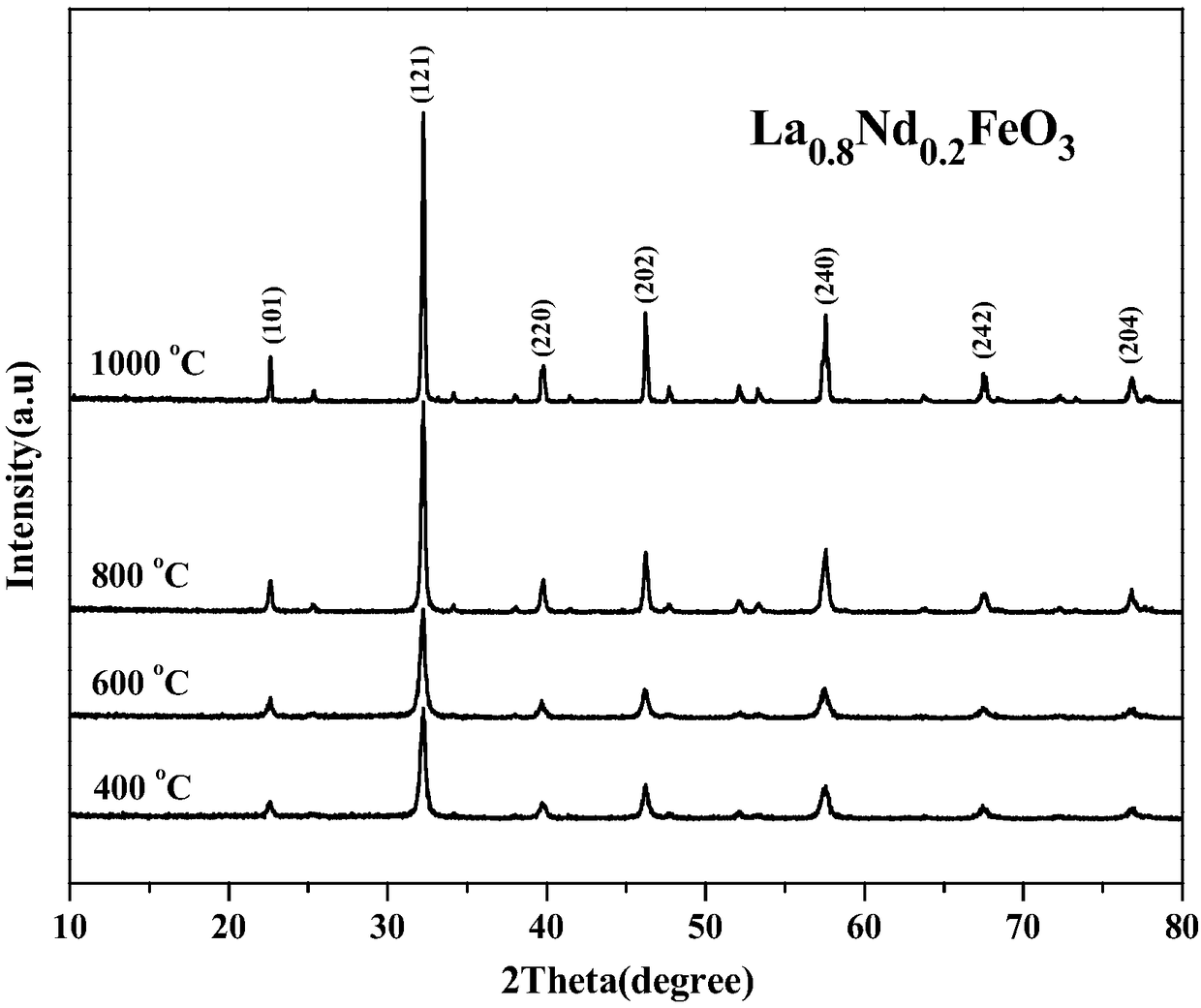

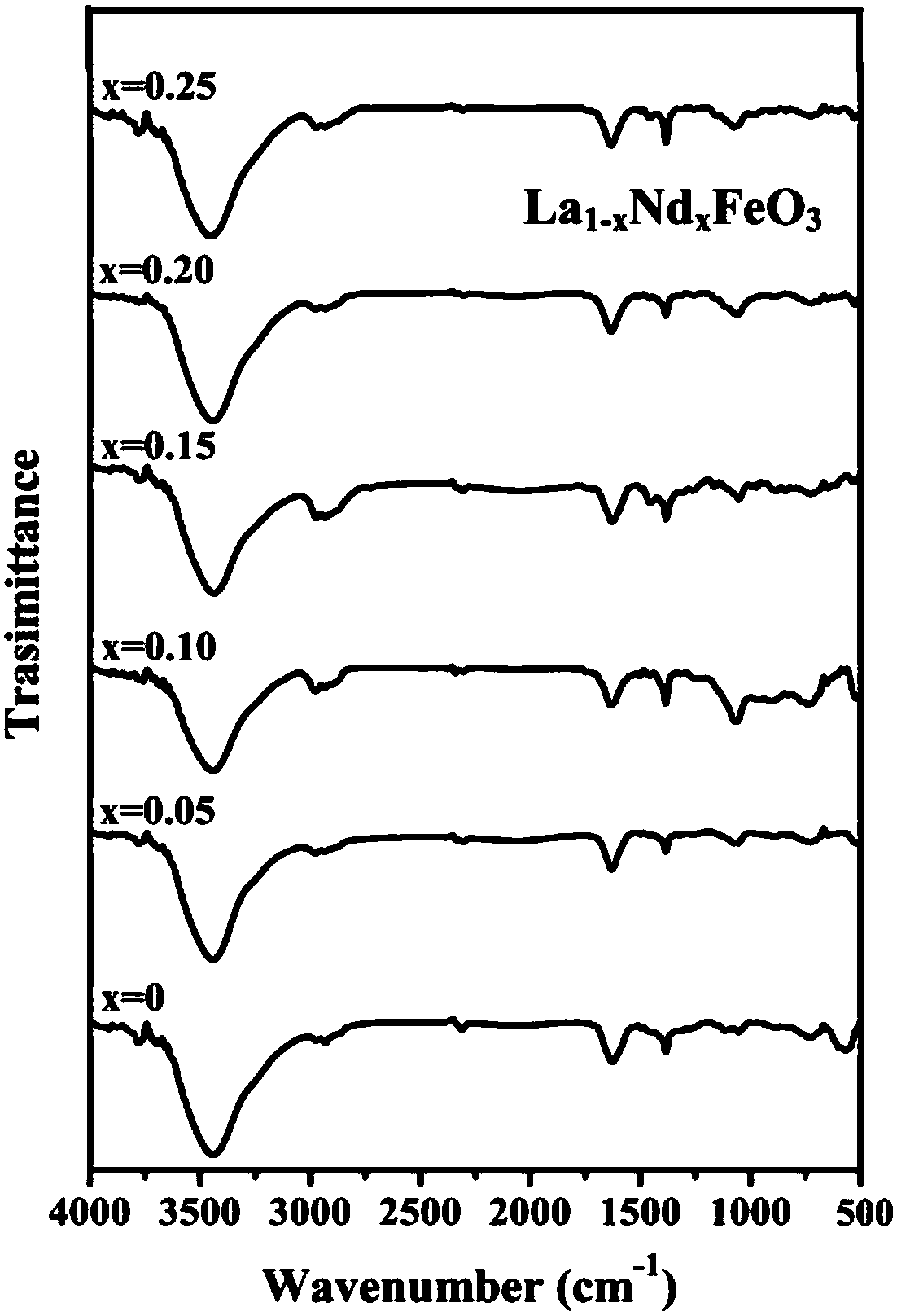

[0033] A kind of La provided by the invention 1-x Nd x FeO 3 The preparation method of nanocrystalline material comprises the following steps:

[0034] S1, dissolving citric acid in deionized water, stirring and dissolving completely to obtain a citric acid solution;

[0035] S2, weigh La(NO 3 ) 3 ·nH 2 O, Fe(NO 3 ) 3 9H 2 O, Nd(NO 3 ) 3 ·6H 2 O, added to the citric acid solution obtained in S1, wherein, La(NO 3 ) 3 ·nH 2 O, Fe(NO 3 ) 3 9H 2 O, Nd(NO 3 ) 3 ·6H 2 The molar ratio of O is (1-x):1:x, and the value range of x is 0.0 to 0.25, then add deionized water, stir and completely dissolve to obtain a perovskite oxide mixed solution;

[0036] S3, adding ammonia water to the perovskite oxide mixed solution obtained in S2, and stirring until pH = 6.9-7.1, to obtain a dark green and clear reaction solution;

[0037] S4, placing the reaction solution obtained in S3 in a water bath at 40-80°C, stirring for 2-5 hours to obtain a wet gel, stopping stirring, stan...

Embodiment 1

[0041] A La 1-x Nd x FeO 3 (x=0.05) the preparation method of nanocrystalline material, concrete steps are as follows:

[0042] S1, take 0.04mol of citric acid and dissolve it in 20ml of deionized water, stir and dissolve completely to obtain a colorless, transparent and clear citric acid solution;

[0043] S2, weigh 0.019mol of La(NO 3 ) 3 ·nH 2 O, 0.02mol of Fe(NO 3 ) 3 9H 2 O, 0.001mol of Nd(NO 3 ) 3 ·6H 2 O was added to the citric acid solution obtained in S1, then 30ml of deionized water was added, and after stirring to dissolve completely, a deep wine red clear perovskite oxide mixed solution was obtained;

[0044] S3, add ammonia water to the perovskite oxide mixed solution obtained in S2, stir until the solution pH=7 is measured by a precision pH meter, and a dark green clear reaction solution (about 60-70 ml) is obtained, and the concentration of the ammonia water is 25 ~28g / 100g;

[0045] S4, put the reaction solution obtained in S3 in a 60°C water bath,...

Embodiment 2

[0048] A La 1-x Nd x FeO 3 (x=0.10) the preparation method of nanocrystalline material, concrete steps are as follows:

[0049] S1, take 0.04mol of citric acid and dissolve it in 20ml of deionized water, stir and dissolve completely to obtain a colorless, transparent and clear citric acid solution;

[0050] S2, weigh 0.018mol of La(NO 3 ) 3 ·nH 2 O, 0.02mol of Fe(NO 3 ) 3 9H 2 O, 0.002mol of Nd(NO 3 ) 3 ·6H 2 O was added to the citric acid solution obtained in S1, then 30ml of deionized water was added, and after stirring to dissolve completely, a deep wine red clear perovskite oxide mixed solution was obtained;

[0051] S3, add ammonia water to the perovskite oxide mixed solution obtained in S2, stir until the solution pH=7 is measured by a precision pH meter, and a dark green clear reaction solution (about 60-70 ml) is obtained, and the concentration of the ammonia water is 25 ~28g / 100g;

[0052] S4, put the reaction solution obtained in S3 in a 60°C water bath,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com