Polyurea-melamin resin double-wall material cetane microcapsule and preparation method thereof

A technology of melamine resin and hexadecane, which is applied in the field of preparation of microcapsules of phase change materials, can solve the problems of insufficient density and strength of microcapsule wall materials, and achieve enhanced impermeability, smooth and dense surface, and thermal stability sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

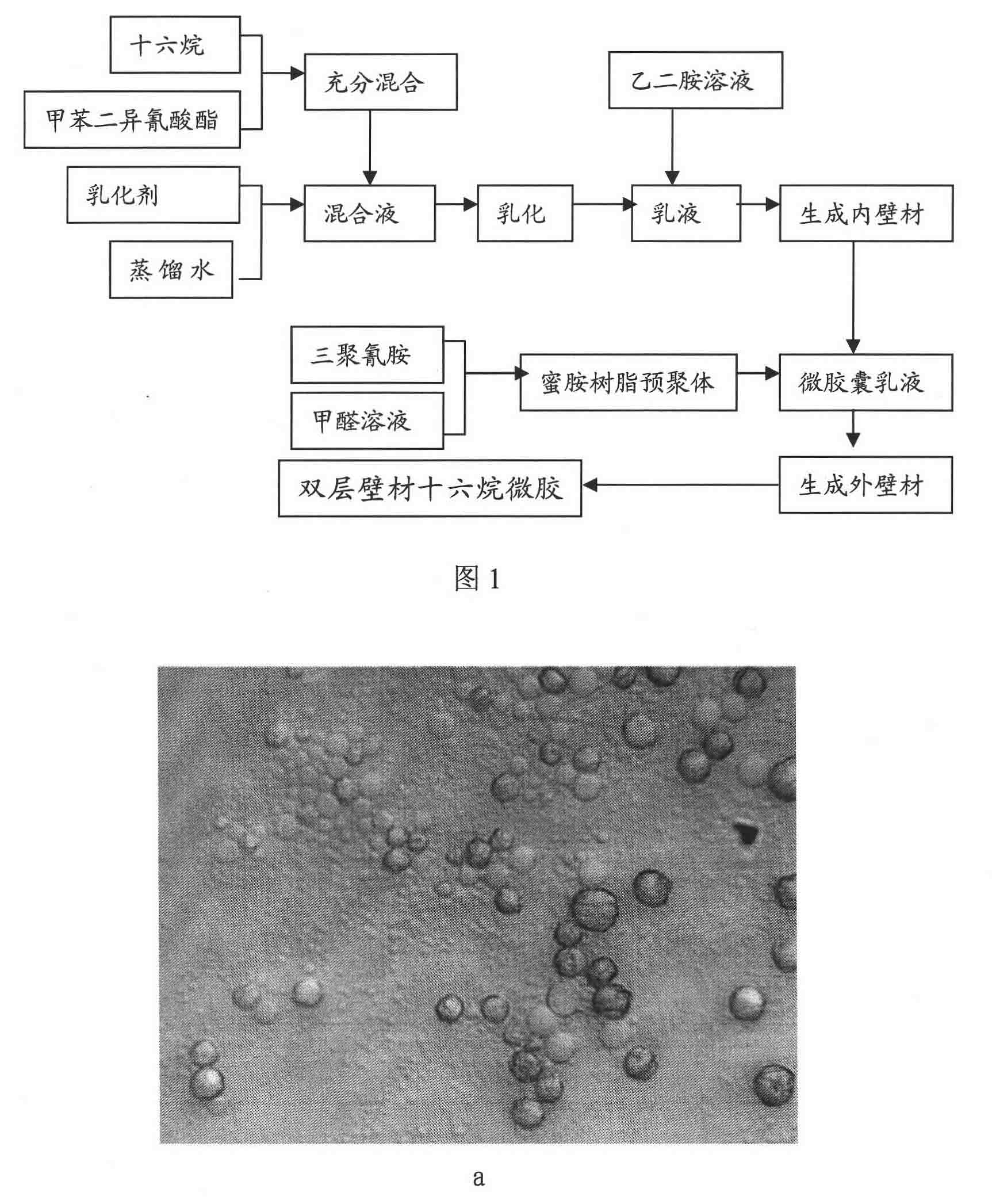

Method used

Image

Examples

Embodiment 1

[0041] Mix 10g of n-hexadecane and 1g of toluene-2,4-diisocyanate thoroughly and add them to a conical flask containing 70g of deionized water, 0.6g of sodium lauryl sulfate and 0.5g of OP emulsifier, at 50°C Next, emulsify on a high-shear emulsifier with a rotating speed of 10000r / min for 15min to make a hexadecane emulsion and move it into a 250ml three-necked bottle;

[0042] Prepare 1.5g of ethylenediamine into a 10%wt solution, and add it dropwise to the hexadecane emulsion at a rate of 0.4ml / min in a water bath at 50°C at a stirring speed of 300r / min. The reaction was carried out at ℃ for 2 hours to obtain hexadecane microcapsule suspension with a single-layer shell material.

[0043] Add 10g of melamine into a three-necked flask containing 20g of 37%wt formaldehyde solution and 40g of distilled water, adjust the pH to 8-9 with 10%wt triethanolamine, stir at 200r / min at 70°C until transparent and viscous liquid to obtain a melamine resin prepolymer.

[0044] At a stirr...

Embodiment 2

[0046] After fully mixing 10g n-hexadecane and 1.5g toluene-2,4-diisocyanate, add it to the conical flask filled with 70g deionized water, 0.5g sodium lauryl sulfate and 0.5g OP emulsifier, 50 Emulsify on a high-shear emulsifier at a speed of 8000r / min for 10min at ℃ to make a hexadecane emulsion and transfer it into a 250ml three-necked bottle;

[0047] Prepare 2.0g of ethylenediamine into a 10%wt solution, and add it dropwise to the hexadecane emulsion at a rate of 0.3ml / min in a water bath at 50°C at a stirring speed of 400r / min. The reaction was carried out at ℃ for 2 hours to obtain a suspension of hexadecane microcapsules with a single-layer polyurea shell material.

[0048] Add 10g of melamine into a three-necked flask containing 20g of 37%wt formaldehyde solution and 40g of distilled water, adjust the pH to 8-9 with 10%wt triethanolamine, stir at 100r / min at 70°C until transparent and viscous liquid to obtain a melamine resin prepolymer.

[0049] At a stirring speed ...

Embodiment 3

[0051] After fully mixing 10g n-hexadecane and 1.3g toluene-2,4-diisocyanate, add in the conical flask filled with 70g deionized water, 0.55g sodium lauryl sulfate and 0.45g OP emulsifier, 50 Emulsify on a high-shear emulsifier at a speed of 9000r / min for 12 minutes at ℃ to make a hexadecane emulsion and transfer it into a 250ml three-necked bottle;

[0052] Prepare 1.7g of ethylenediamine into a 10%wt solution, and add it dropwise to the hexadecane emulsion at a rate of 0.3ml / min in a water bath at 50°C at a stirring speed of 350r / min. The reaction was carried out at ℃ for 2 hours to obtain hexadecane microcapsule suspension with a single-layer shell material.

[0053] Add 10g of melamine into a three-necked flask containing 20g of 37%wt formaldehyde solution and 40g of distilled water, adjust the pH to 8-9 with 10%wt triethanolamine, stir at 100r / min at 70°C until transparent and viscous liquid to obtain a melamine resin prepolymer.

[0054] At a stirring speed of 220r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

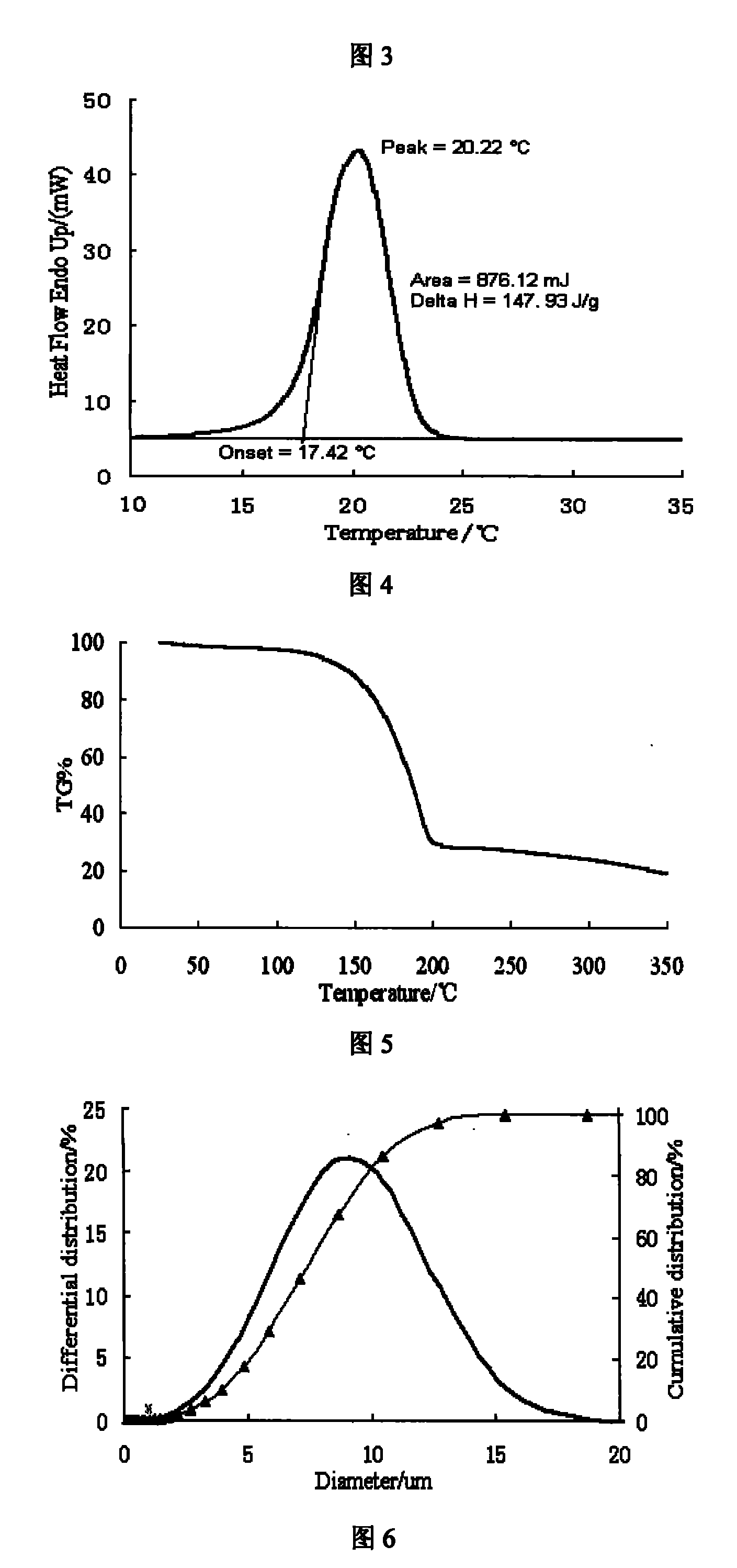

| phase transition enthalpy | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com