Beam shaping illumination system of semiconductor laser array

A laser array and beam shaping technology, applied in semiconductor laser devices, semiconductor devices of light-emitting elements, laser devices, etc., can solve the problems of difficult integration, high production cost, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

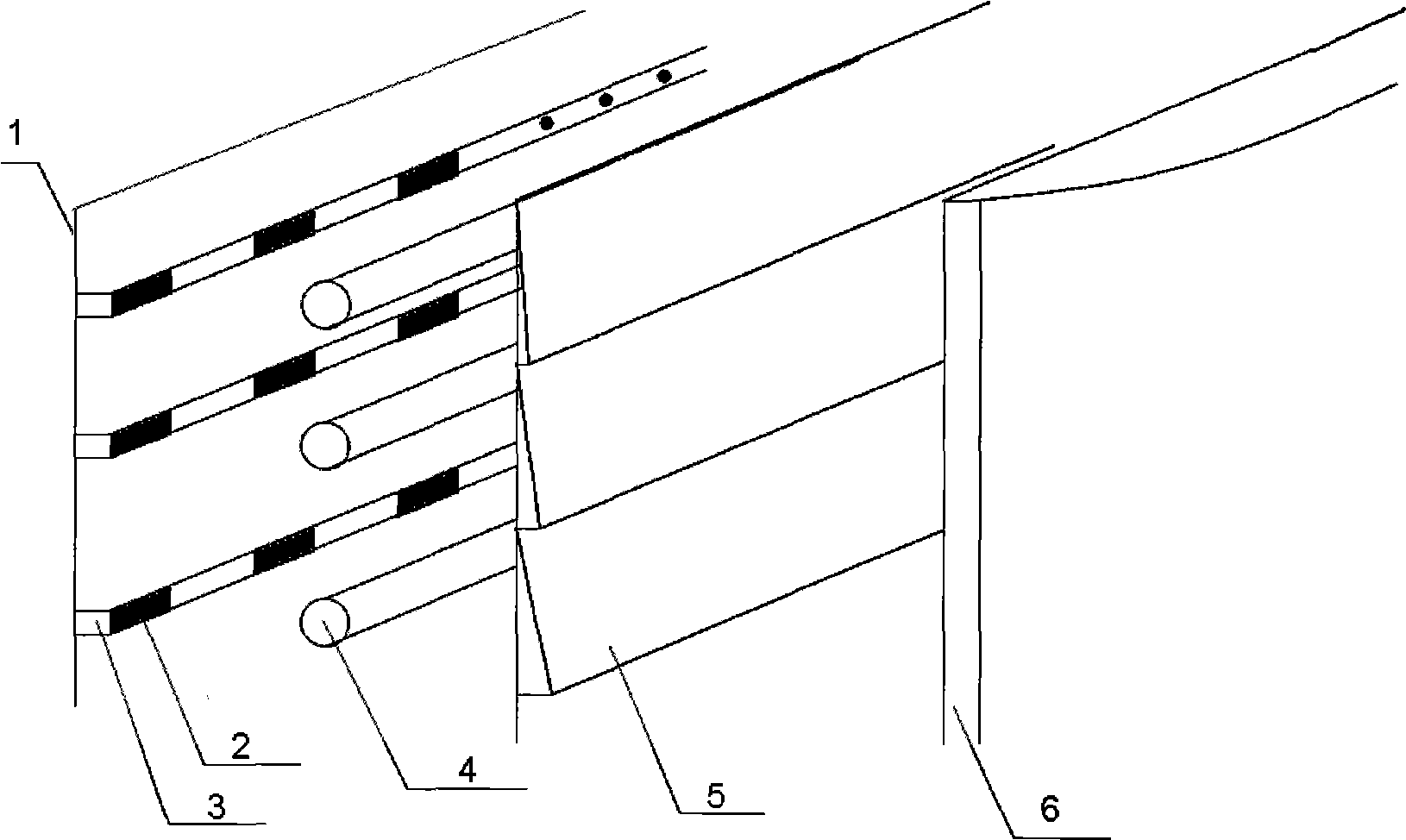

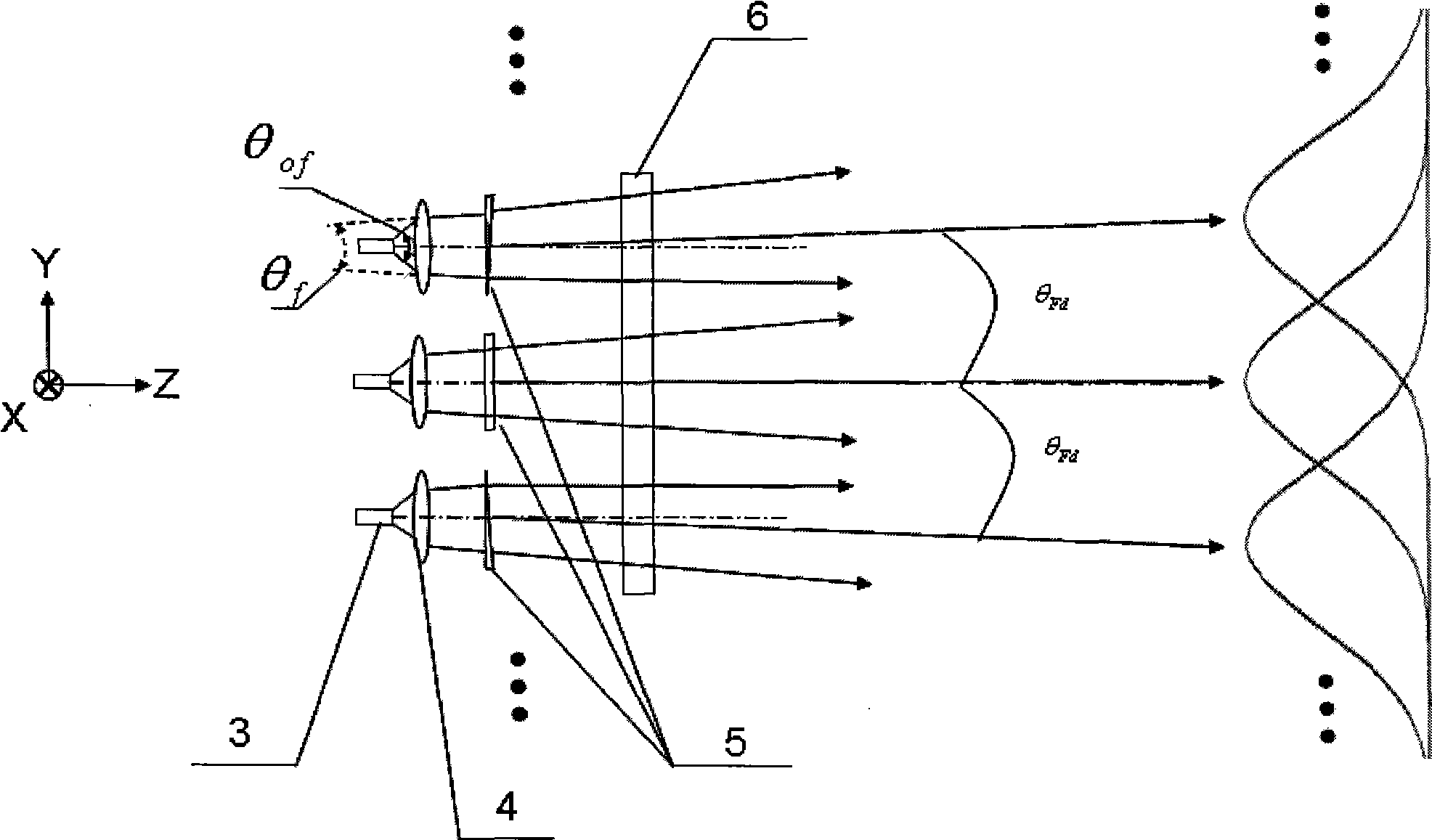

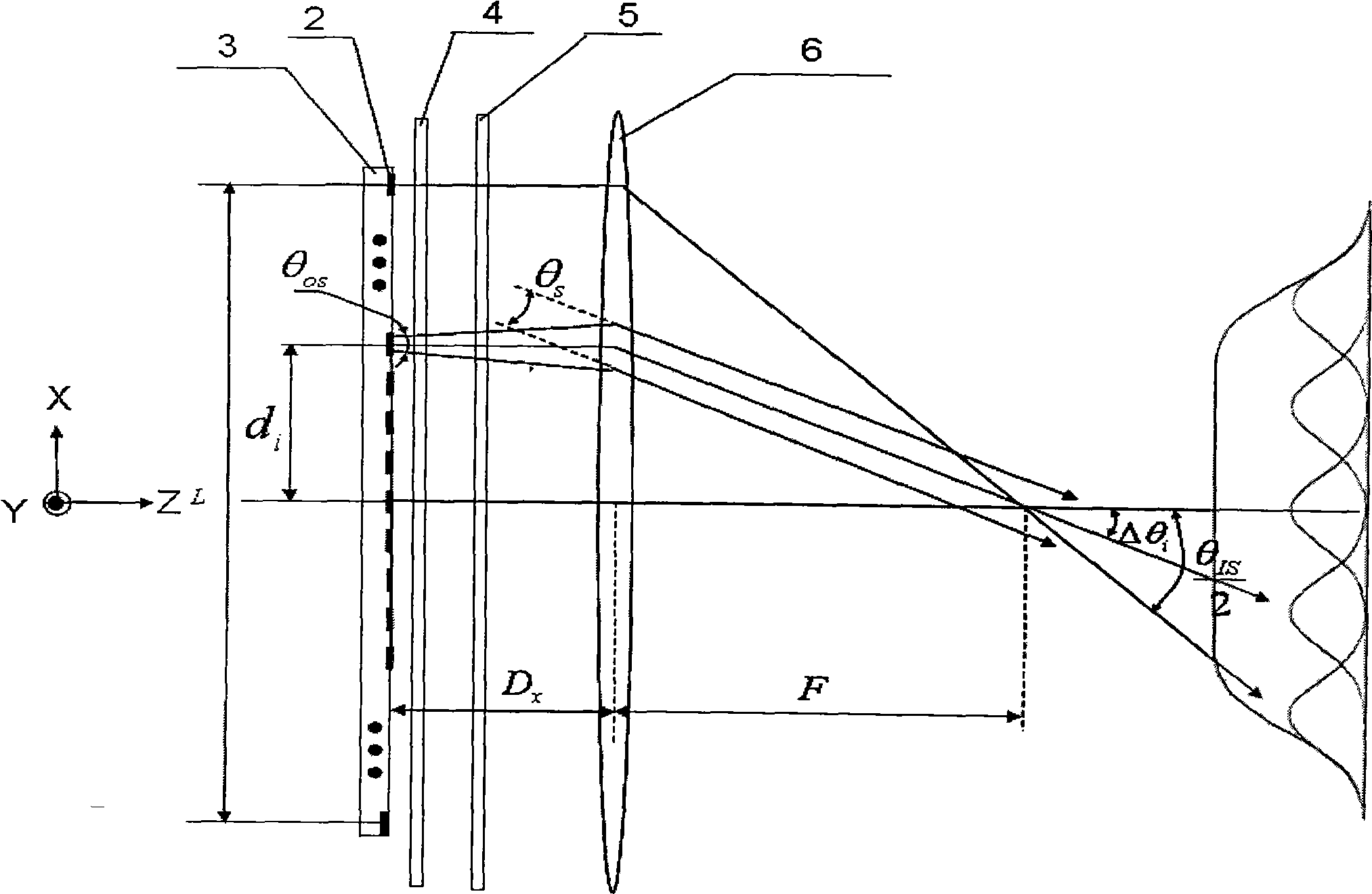

[0059] exist figure 1 Among them, the semiconductor laser two-dimensional array 1, the microcylindrical lens array 4, the optical wedge array 5, and the cylindrical lens 6 are arranged in sequence along the laser propagation direction, wherein each microcylindrical lens busbar of the microcylindrical lens array 4 is connected to the semiconductor laser The line direction of the line array 3 is parallel and arranged in one-to-one alignment, the unit optical wedges in the wedge array 5 are aligned and arranged in a one-to-one alignment with the semiconductor laser line array 3, and the busbar of the cylindrical lens 6 is perpendicular to the semiconductor laser line array 3 and The optical axis of the cylindrical lens 6 coincides with the mid-perpendicular line of the semiconductor laser bar array 3 . Take a 900W 808nm semiconductor laser stack array (stack) to form a 10-degree x 10-degree lighting system as an example. The semiconductor laser two-dimensional array 1 is a 900W 8...

Embodiment 2

[0061] exist figure 1 For the two-dimensional array of semiconductor lasers 1, the semiconductor laser unit 2, the semiconductor laser line array 3, the microcylindrical lens array 5, and the optical wedge array 6 Figure 5 , Figure 6 The semiconductor laser line array 7 and the geometrical surface base 8 with fast-axis divergence compressed micro-cylindrical lenses shown in . Take the 800W 808nm semiconductor laser stack array (stack) to form a 10-degree x 10-degree lighting system as an example, wherein the geometric surface base 8 can be as follows Figure 5 As shown, a convex cylindrical surface or a concave cylindrical surface equal to the fast axis field of view angle of 10 degrees, the semiconductor laser line array 7 with the fast axis divergence angle compressed microcylindrical lens is placed on the convex cylindrical surface or the concave cylindrical surface at equal intervals on, it can also be as Figure 6 The angle between the normals of two adjacent planes ...

Embodiment 3

[0063] Such as Figure 7 As shown, it is an integrated extension of the original system. A plurality of integral lighting system units 9 with the same lighting field of view angle are integrated and used as an array of units to increase the total power of the far-field lighting system and enhance uniformity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com