Omeprazole sodium freeze-dried lipidosome preparation and preparation method thereof

A technology of omeprazole sodium and liposome preparation, which is applied in the field of freeze-dried liposome preparation of omeprazole sodium and its preparation, can solve problems such as poor stability, achieve stable product quality, improve therapeutic index, The effect of convenient clinical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

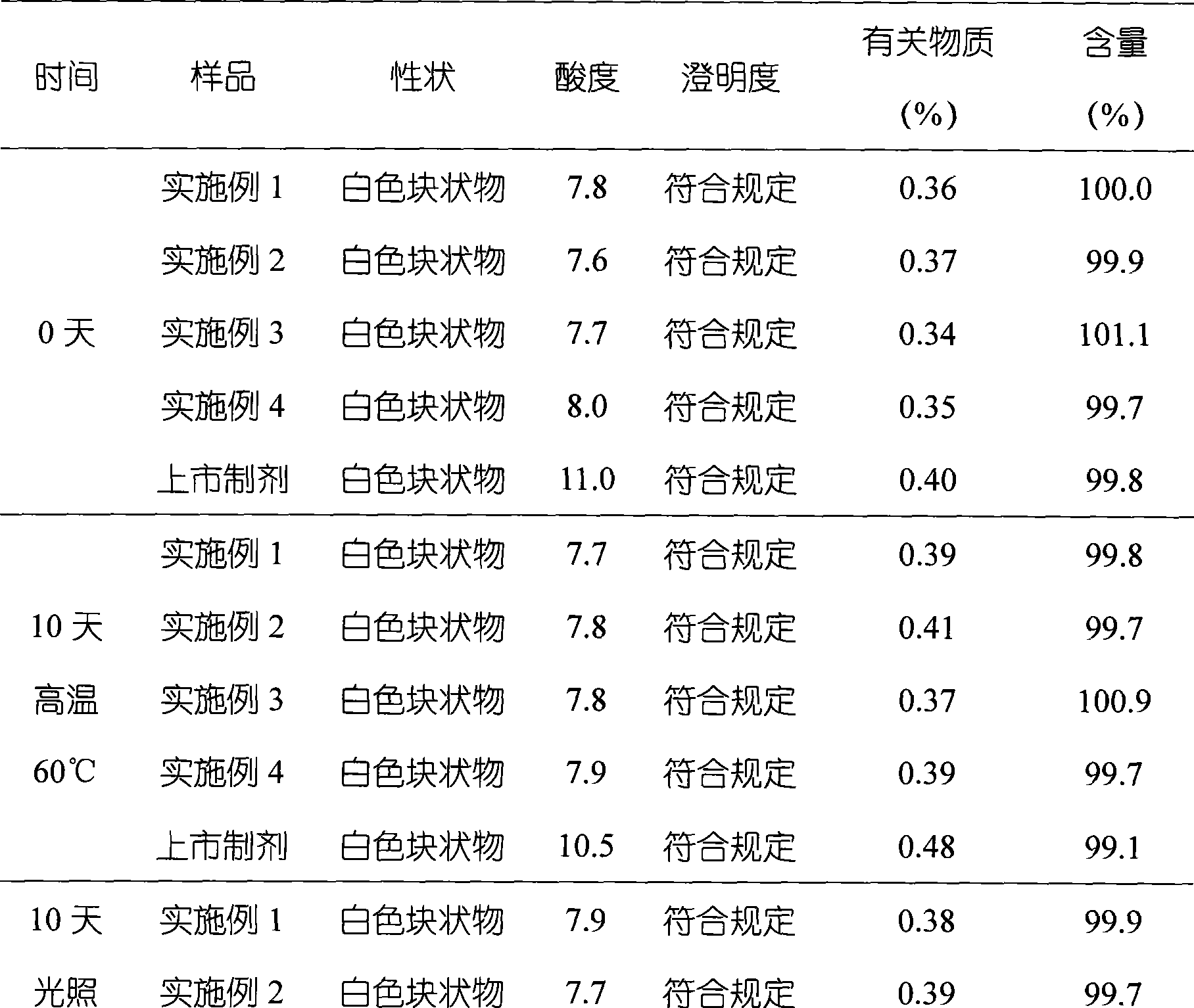

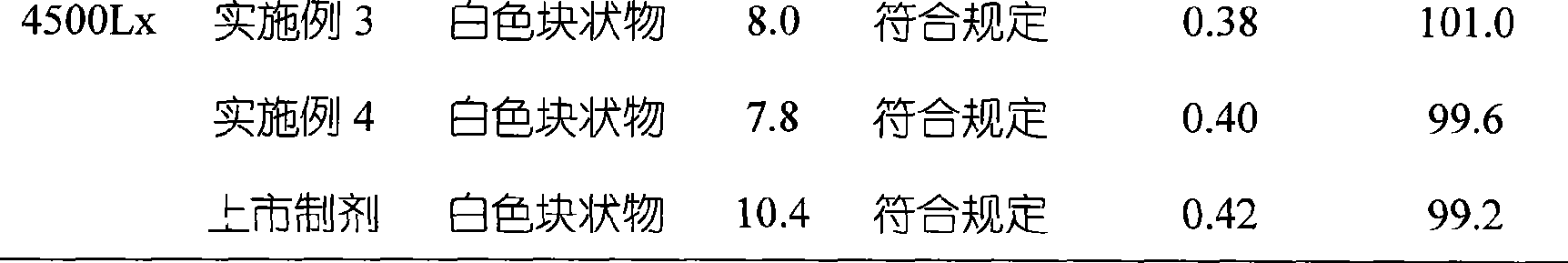

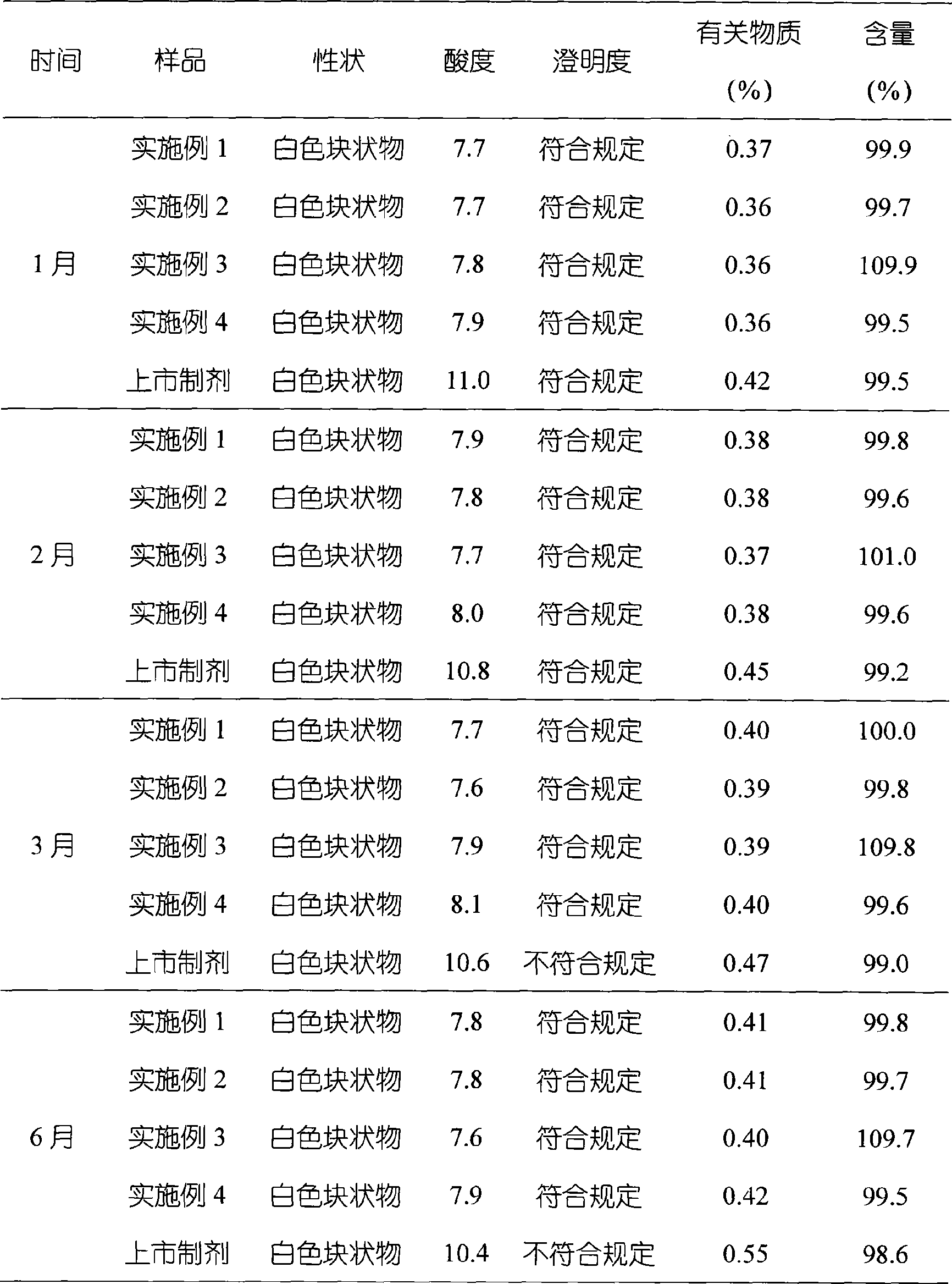

Examples

Embodiment 1

[0040] Embodiment 1 The preparation of omeprazole sodium freeze-dried liposome preparation

[0041] Prescription (1000 bottles): Omeprazole Sodium 40g

[0042] Soy Lecithin 75g

[0043] Cholesterol 20g

[0044] Vitamin E 10g

[0045] Mannitol 40g

[0046] Preparation Process:

[0047] (1) Weigh 75g of soybean lecithin, 20g of cholesterol and 10g of vitamin E and dissolve them in 800ml of ethanol, heat and melt, add a phosphate buffer solution with a pH value of 7.8, heat to remove ethanol, transfer to a tissue masher, and stir at a high speed for 10 minutes, filter, sterilize, and sonicate for 10 minutes;

[0048] (2) In a sterile room, under 100-grade conditions, add 40 g of sterilized omeprazole sodium and 40 g of mannitol to dissolve, filter, and fill in vials;

[0049] (3) Pre-freeze at -35°C for 3 hours, then dry under reduced pressure and vacuum at -45°C to -5°C for 25 hours, and finally dry at 35°C for 5 hour...

Embodiment 2

[0051] Embodiment 2 The preparation of omeprazole sodium freeze-dried liposome preparation

[0052] Prescription (1000 bottles): Omeprazole Sodium 20g

[0054] Cholesterol 5g

[0056] Mannitol 15g

[0057] Lactose 30g

[0058] Preparation Process:

[0059] (1) Take by weighing 20g egg yolk lecithin, 5g cholesterol and sodium bisulfite 7.5g and dissolve in the mixture of 500ml isopropanol and ethanol with a volume ratio of 5:1, heat and melt, add pH value 7.8 citrate buffer solution, Heat to evaporate isopropanol and ethanol, transfer to a tissue masher, stir at high speed for 30 minutes, filter, sterilize, and sonicate for 20 minutes;

[0060] (2) In a sterile room, under 100-grade conditions, add 20 g of sterilized omeprazole sodium, 15 g of mannitol and 30 g of lactose to dissolve, filter, and fill in vials;

[0061] (3) Pre-freeze at -45...

Embodiment 3

[0063] Embodiment 3 The preparation of omeprazole sodium freeze-dried liposome preparation

[0064] Prescription (1000 bottles): Omeprazole Sodium 20g

[0065] Hydrogenated egg yolk lecithin 10g

[0066] Ascorbyl Palmitate 15g

[0067] Sorbitol 10g

[0068] Trehalose 15g

[0069] Preparation Process:

[0070] (1) Weigh 10g of hydrogenated egg yolk lecithin and 15g of ascorbyl palmitate, dissolve them in 500ml of isopropanol and ethanol with a volume ratio of 5:1, heat and melt, add a pH value of 7.8 phosphate buffer solution, heat and evaporate to remove isopropanol Propanol and ethanol, transferred to a tissue masher, stirred at high speed for 20 minutes, filtered, sterilized, and ultrasonicated for 10 minutes;

[0071] (2) In a sterile room, under 100-grade conditions, add 20 g of sterilized omeprazole sodium, 10 g of sorbitol and 15 g of trehalose and dissolve, filter, and fill in vials;

[0072] (3) Pre-freeze a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com