Metal surface treatment agent and printed wiring board with protecting film formed thereby

A technology for metal surface treatment and function, applied in the application of non-metallic protective layer, metal material coating process, secondary treatment of printed circuit, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

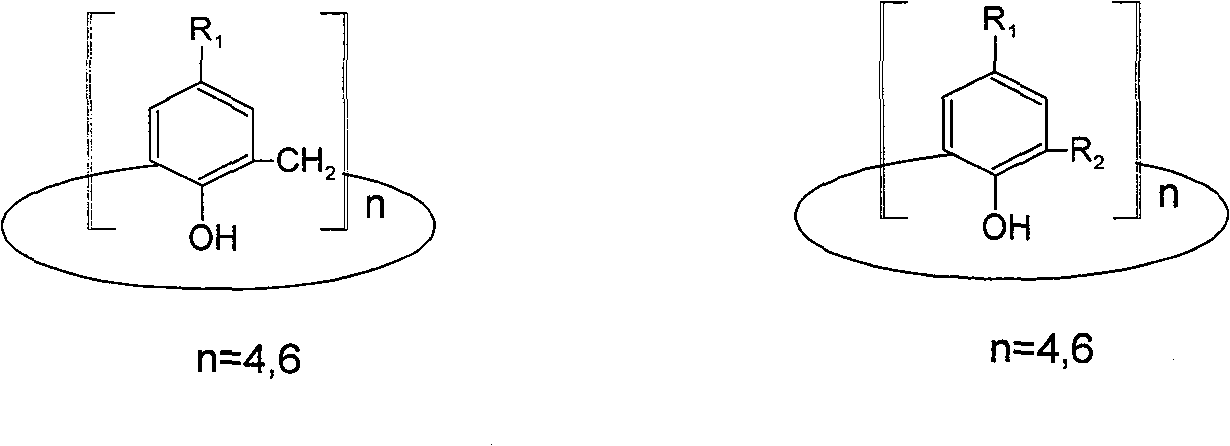

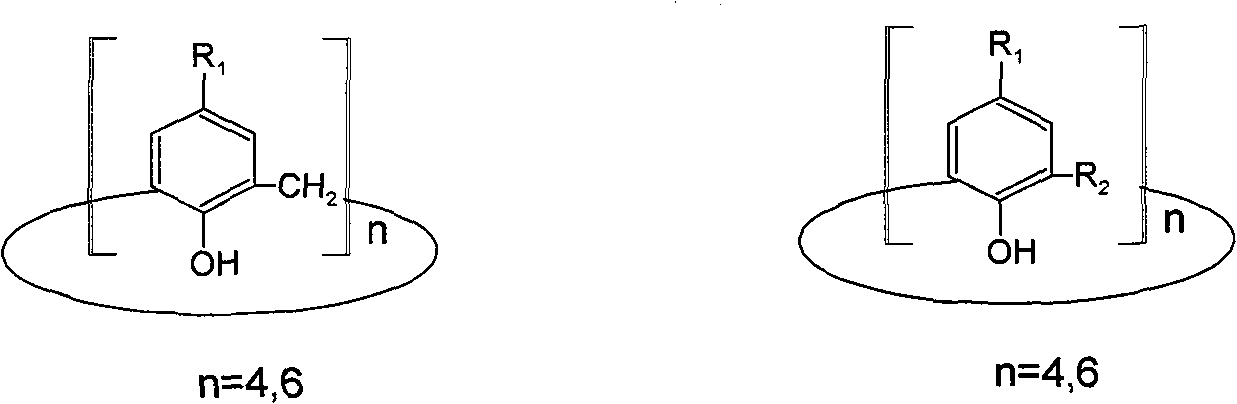

Method used

Image

Examples

Embodiment 1

[0043] The components and the content of each component of the OSP aqueous solution treatment agent of embodiment 1 are shown in Table 1.

[0044] In Example 1, the composition described in Table 1 was dissolved in deionized water, and the pH was adjusted to 3.0 with ammonia water, thereby preparing a metal surface treatment agent. Then, degrease the test piece of the printed circuit board (as a circuit diagram, formed by 10 copper foils of 40×0.7mm, each copper foil is 1mm apart in the width direction), wash with water, and do it in sulfuric acid / hydrogen peroxide. Soak in the microetching agent for 60-120 seconds, wash 3 times with deionized water, dry, soak in 3-5% hydrochloric acid aqueous solution for 15-30 seconds, wash 3 times with deionized water, dry, and place in a surface treatment agent at 40°C Soak for 60 seconds, dry, wash with deionized water 3 times, and dry to form a 0.1-0.5 micron protective film on the surface of the circuit board.

Embodiment 2-10

[0046] A metal surface treatment agent having a composition described in Table 1 was prepared in the same manner as in Example 1. The printed circuit board was treated with the same process as in Example 1, and then the protective film on the PCB was prepared under the conditions recorded in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com