Elastic thrust block and production method thereof

A thrust pad and elastic technology, applied in the field of its manufacturing method, can solve the problems of oil film damage, low temperature adaptation, uneven elastic modulus, etc., achieve uniformity of elastic modulus, improve wear resistance and thermal conductivity, and improve The effect of uneven porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

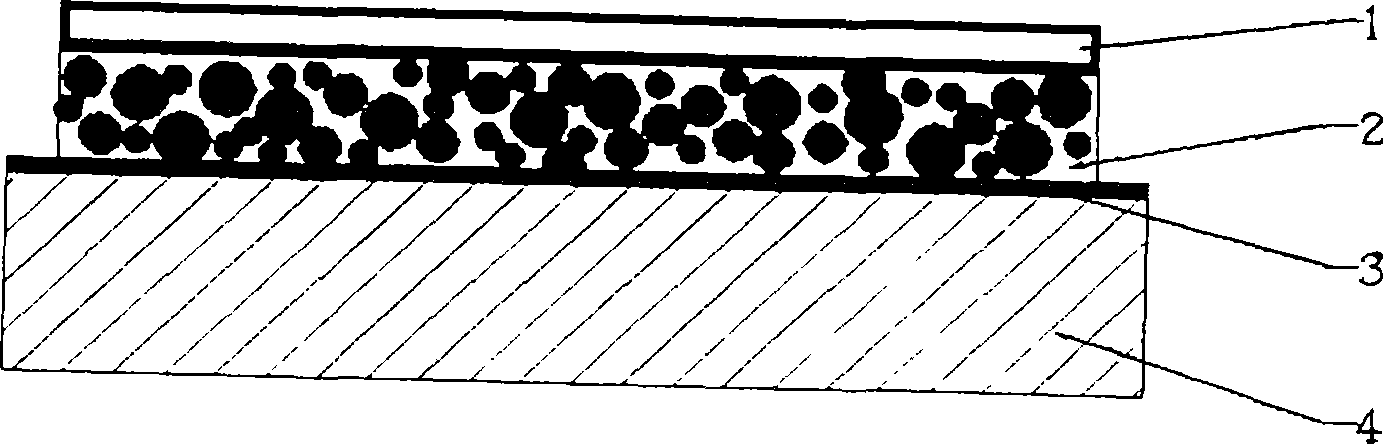

Image

Examples

Embodiment 2

[0028] According to the manufacturing method described in Example 1 to produce elastic thrust tiles, the filling depth of modified polytetrafluoroethylene is 1 / 2 of the matrix, and the thickness of the wear-resistant layer is 0.5, wherein the modified polytetrafluoroethylene is prepared according to the following raw material weight percentages. Composition: 20% copper powder; 2% molybdenum disulfide, 78% polytetrafluoroethylene.

Embodiment 3

[0030] According to the manufacturing method described in Example 1 to produce elastic thrust tiles, the filling depth of modified polytetrafluoroethylene is 1 / 3 of the matrix, and the thickness of the wear-resistant layer is 2.5mm, wherein the modified polytetrafluoroethylene is prepared according to the following raw material weight percentages Made of: 18% copper powder; 2% molybdenum disulfide, 80% polytetrafluoroethylene.

[0031] The elastic thrust pad that the present invention makes is as follows through detection performance data:

[0032] Thermal conductivity (W / mk) 0.32

[0033] Coefficient of thermal expansion (cm / cm.℃) 1.68×10 -5

[0034] Elastic membrane volume (MPa) ≥1.9×10 3

[0035] Friction coefficient (drip oil lubrication) 0.011—0.130

[0036] Wear coefficient (dripping oil lubrication) ≤0.23.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com