Delivery equipment for antioxidation of oil products and preparation method thereof

An anti-oxidation and equipment technology, applied in the field of anti-oxidation, can solve the problems of not crispy food, waste of machine oil, greasy food, etc., and achieve the effect of high hardness, good weather resistance, and slow down the oxidation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

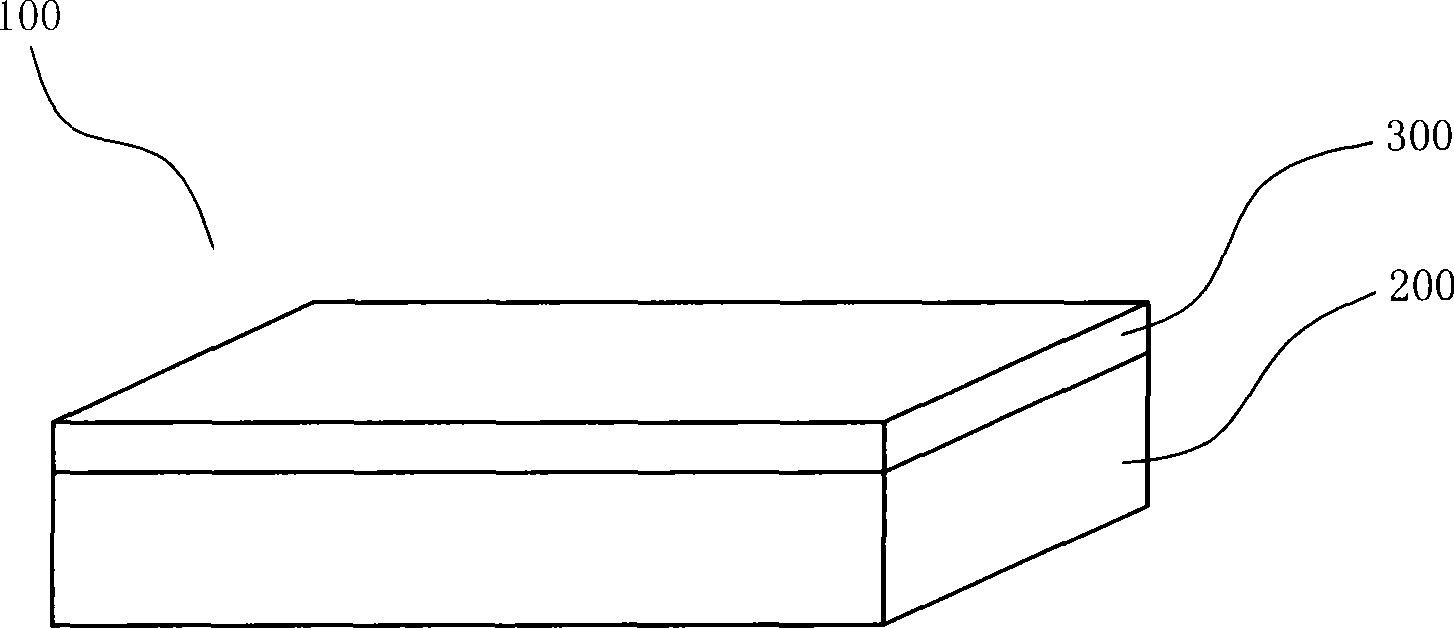

[0043] ginseng figure 1 As shown, the oil anti-oxidation dispensing device 100 described in the present invention mainly includes two parts: a dispensing device substrate 200 and an anti-oxidation functional layer 300 .

[0044] Wherein the delivery device substrate 200, as a good example without limitation, can adopt one or more of the following structures:

[0045] For the sheet structure sheet type delivery equipment 110, refer to figure 2 shown. The sheet-like structure can be various sheet structures, such as circular sheets, square sheets, rectangular sheets, and sheets of various irregular shapes, and so on.

[0046] For the ball type throwing equipment 120 of spherical structure, refer to image 3 shown. This type of delivery device can be either a solid sphere or a hollow sphere, and its size can be set as required.

[0047] Be the bar type throwing equipment 130 of strip structure, refer to Figure 4 shown. This refers to a delivery device with a thin strip s...

Embodiment 2

[0068] Composition Weight

[0069] Water-dispersed nano-scale alumina 380kg

[0070] Pigment 90kg

[0071] Packing 70kg

[0072] Potassium titanate whiskers 60kg

[0073] Nano silver particles 10kg

[0074] Methyltrimethoxysilane 340kg

[0075] Methyltriethoxysilane 50kg

[0076] These components add up to a total of 1000 kg.

[0077] The particle size of the alumina in the water-dispersed nano-scale alumina can be selected to be 15 nanometers.

[0078] The pigment, in this embodiment, can be silica fume powder, which makes the anti-oxidation functional layer appear taupe, and has very good dirt and dust resistance.

[0079] The filler therein may be nanoscale precipitated barium sulfate. The particle size of the barium sulfate can be selected to be between 10-100 nanometers.

[0080] The potassium titanate whiskers may be potassium tetratitanate whiskers.

specific Embodiment 3

[0082] An anti-oxidation functional layer can also be made according to the following formula:

[0083] Composition Weight

[0084] Water-dispersed nano-scale alumina 320kg

[0085] Pigment 110kg

[0086] Packing 80kg

[0087] Potassium titanate whiskers 80kg

[0088] Nano silver particles 40kg

[0089] Methyltrimethoxysilane 260kg

[0090] Methyltrichlorosilane 40kg

[0091] Phenyltrimethoxysilane 20kg

[0092] Methyltriethoxysilane 50kg

[0093] Together it is 1000kg.

[0094] The particle size of the alumina in the water-dispersed nano-scale alumina can be selected to be 25 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com