Method for preparing nucleocapsid structure lithium ion battery alloy composite cathode material

A lithium-ion battery and negative electrode material technology, applied in the field of material science, can solve the problems of pollution and waste, difficulty in recycling surfactants, and low yield, and achieve the effects of simple process, excellent electrochemical performance, and low technical cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

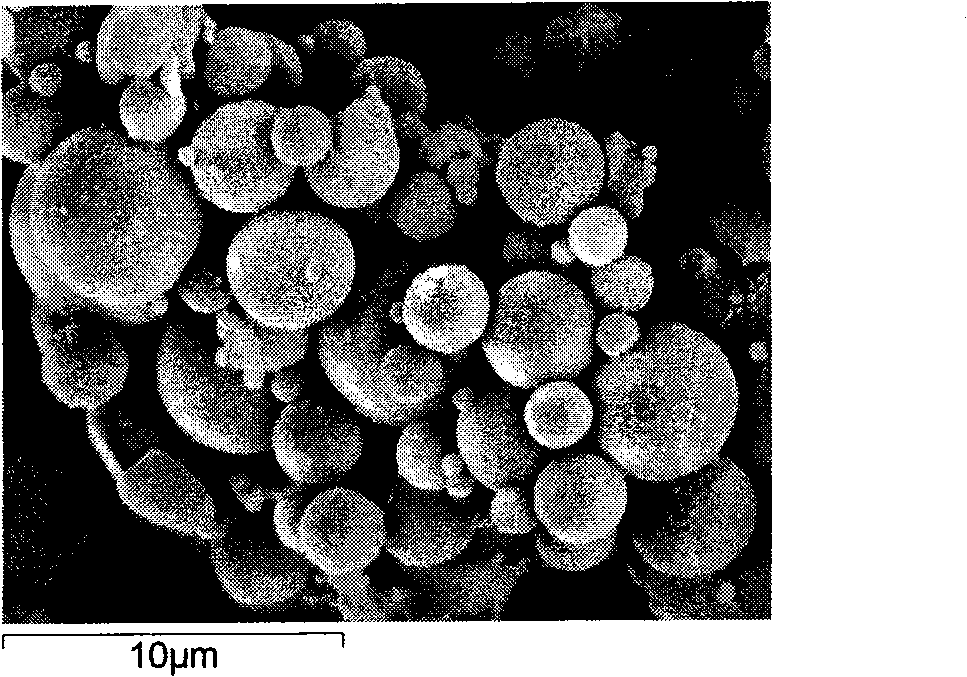

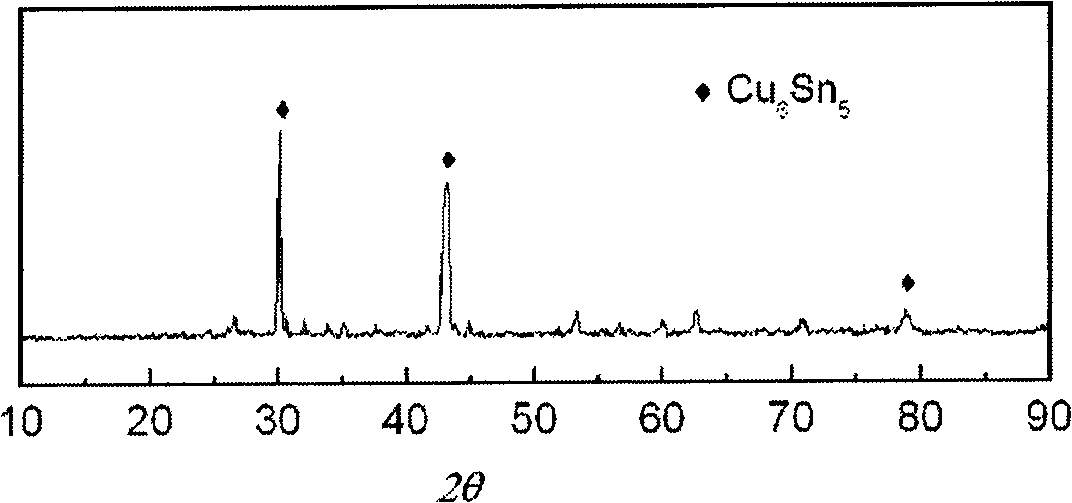

Embodiment 1

[0020] Weigh CuO and SnO according to the ratio of Cu:Sn molar ratio of 6:5 2 Nano oxide, then resin: (CuO+SnO by weight 2 )=5:3. Weigh 60wt% water-soluble phenolic resin solution, add deionized water to prepare 15wt% solution. The obtained solution was dried with an air flow spray dryer, and the feed solution was injected with a peristaltic pump at a speed of 15ml / min; the gas flow rate of the nozzle was controlled by the pressure of the compressed air, and atomization was generated at about 0.4MPa; the air inlet temperature was controlled The temperature at the outlet is 300°C, and the outlet temperature is 130°C; the outlet air is separated and vented by the first-stage vortex. The phenolic resin with core-shell structure obtained by spray drying and spherical powders of tin dioxide and copper oxide were calcined under the protection of high-purity nitrogen at 1000℃ for 5 hours to obtain Cu with a spherical core-shell structure 6 Sn 5 / C composite anode material, figure...

Embodiment 2

[0022] Weigh Co according to the ratio of Co:Sn molar ratio of 1:2 3 O 4 and SnO 2 Nano oxide, then resin: (Co by weight 3 O 4 +SnO 2 )=5:3. Weigh 60wt% water-soluble phenolic resin solution, add deionized water to prepare 15wt% solution. The obtained solution was dried with an air flow spray dryer, and the feed solution was injected with a peristaltic pump at a speed of 15ml / min; the gas flow rate of the nozzle was controlled by the pressure of the compressed air, and atomization was generated at about 0.4MPa; the air inlet temperature was controlled The temperature is 300°C, and the outlet temperature is 120°C; the outlet air is separated and vented by the first-stage vortex. The phenolic resin with core-shell structure obtained by spray drying, tin dioxide and three diamond tetroxide spherical powders were calcined at 900 ℃ under the protection of high-purity nitrogen for 10 hours to obtain spherical core-shell structure CoSn 2 / C composite anode material. Using the ...

Embodiment 3

[0024] Weigh Sb according to the molar ratio of Sb:Sn of 1:1 2 O 3 and SnO 2 Nano oxide, then resin: (Sb by weight 2 O 3 +SnO 2 )=5:1 The alcohol-soluble phenolic resin powder was weighed, and ethanol was added to prepare a 20wt% solution. The obtained solution was dried with an air-flow spray dryer, and the feed solution was injected with a peristaltic pump at a speed of 10ml / min; the gas flow rate of the nozzle was controlled by the pressure of the compressed air, and atomization was generated at about 0.4MPa; the air inlet temperature was controlled The temperature at the outlet is 300°C, and the outlet temperature is 100°C; the outlet air is separated and vented by the first-stage vortex. The core-shell structure phenolic resin and tin dioxide and antimony trioxide spherical powder obtained by spray drying were calcined at 800 °C under the protection of high-purity nitrogen for 10 hours to obtain a spherical core-shell structure SnSb / C composite negative electrode mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com