Method for measuring free polyethyleneglycol content in sample or products

A polyethylene glycol and detection method technology, applied in the direction of measuring devices, material separation, instruments, etc., can solve the problems of unsuitable complex sample analysis, inapplicability, etc., achieve high sensitivity, avoid interference, and expand the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

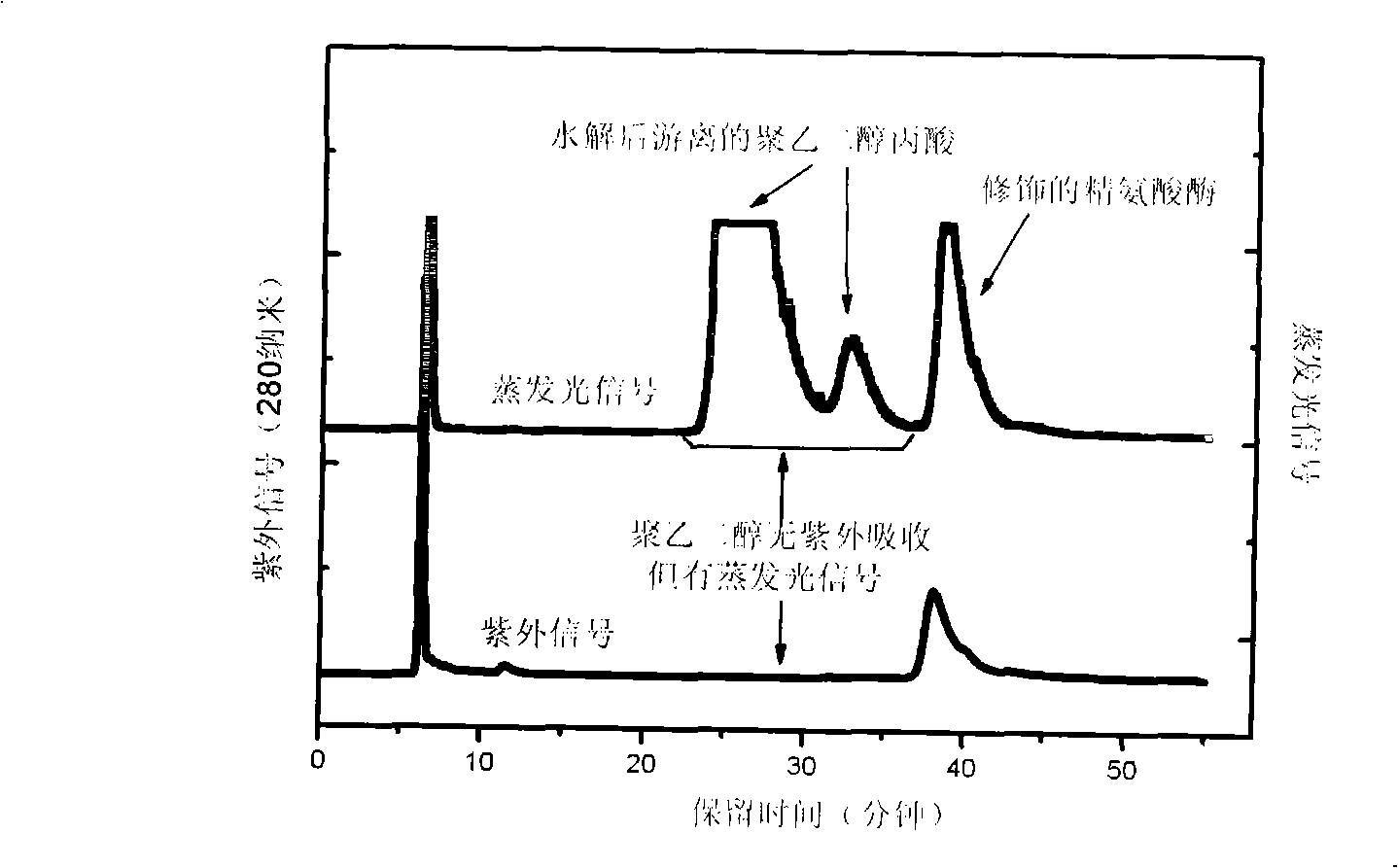

Embodiment 1

[0036] The detection sample is a recombinant human arginase (EC 3.5.3.1) modified by monomethoxypolyethylene glycol activated by succinimidyl propionic acid with 40 times the molar amount, the reaction is carried out at room temperature, and then 0.2 mol / The pH of the reaction mixture was adjusted to 4.0 with 1 liter of citric acid. The main components of the sample mixture are unmodified recombinant human arginase, modified recombinant human arginase and hydrolyzed monomethoxypolyethylene glycol propionic acid. The reaction mixture was diluted with ultrapure water to a concentration of the monomethoxypolyethylene glycol derivative of about 10-15 mg / ml.

[0037] The instrument is Agilent 1200 chromatographic system: Vydac 214TP54 (250×4.6mm, 5μm, ) chromatographic column, DAD diode array detector with SEDEX75 evaporative light detector, automatic sampler, quaternary pump, column thermostat, and workstation.

[0038] The mobile phase was chromatographic grade acetonitrile, ...

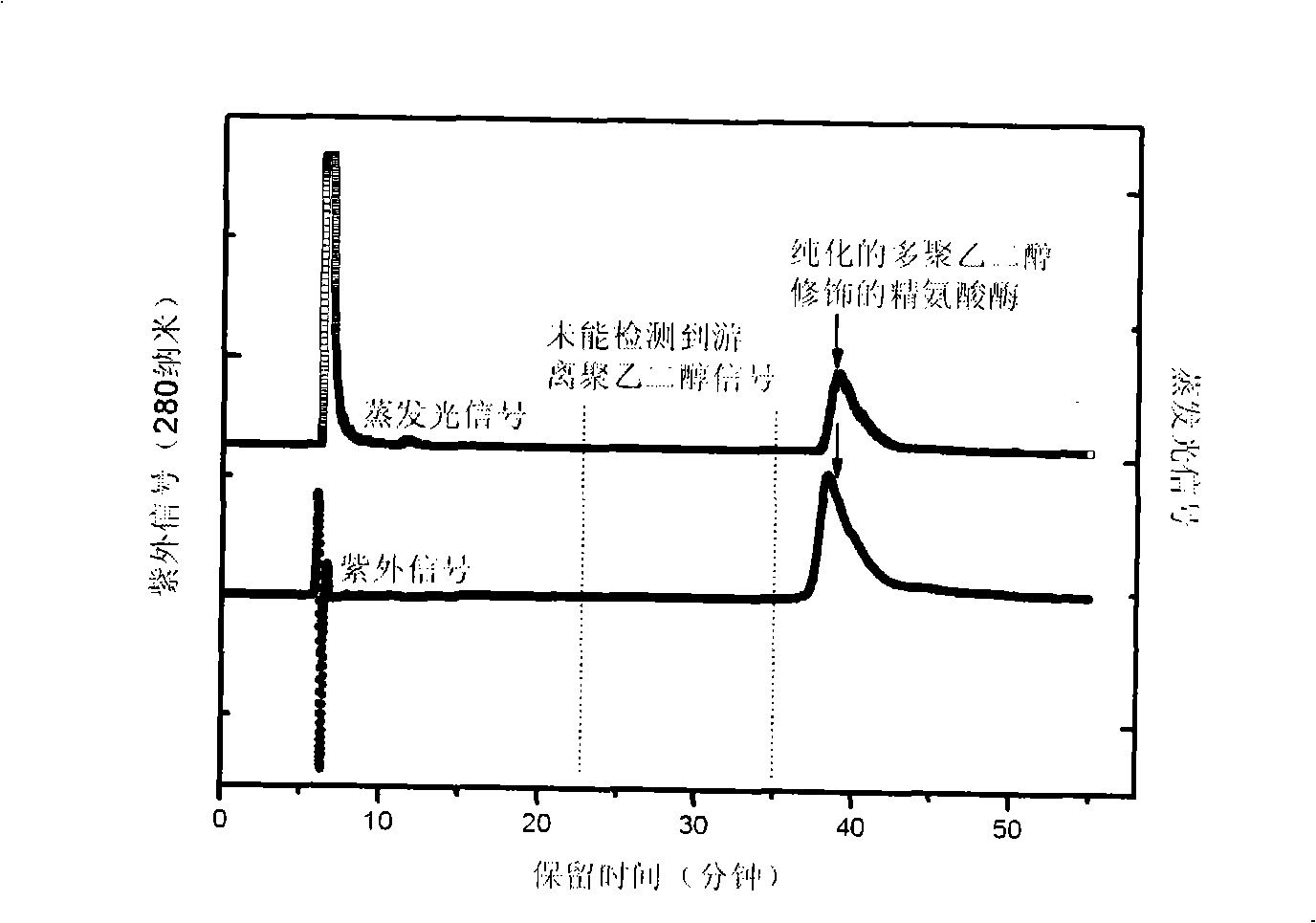

Embodiment 2

[0049] The detection sample is a polyethylene glycol-modified recombinant human arginase sample purified by gel exclusion chromatography well known in the art. The instrument is Agilent 1200 chromatographic system: Vydac 214TP54 (250×4.6mm, 5μm, ) chromatographic column, DAD diode array detector with SEDEX75 evaporative light detector, automatic sampler, quaternary pump, column thermostat, and workstation.

[0050] The mobile phase was chromatographic grade acetonitrile, trifluoroacetic acid and ultrapure water.

[0051] Monomethoxypolyethylene glycol succinimidyl propionic acid and monomethoxypolyethylene glycol (both molecular weight 20,000 Daltons) were purchased from NEKTAR Company.

[0052] Chromatographic conditions:

[0053] Running buffer: ultrapure water containing 0.1% trifluoroacetic acid by volume, which becomes buffer A in the present invention; acetonitrile containing 0.1% trifluoroacetic acid by volume, which becomes buffer B in the present invention;

[005...

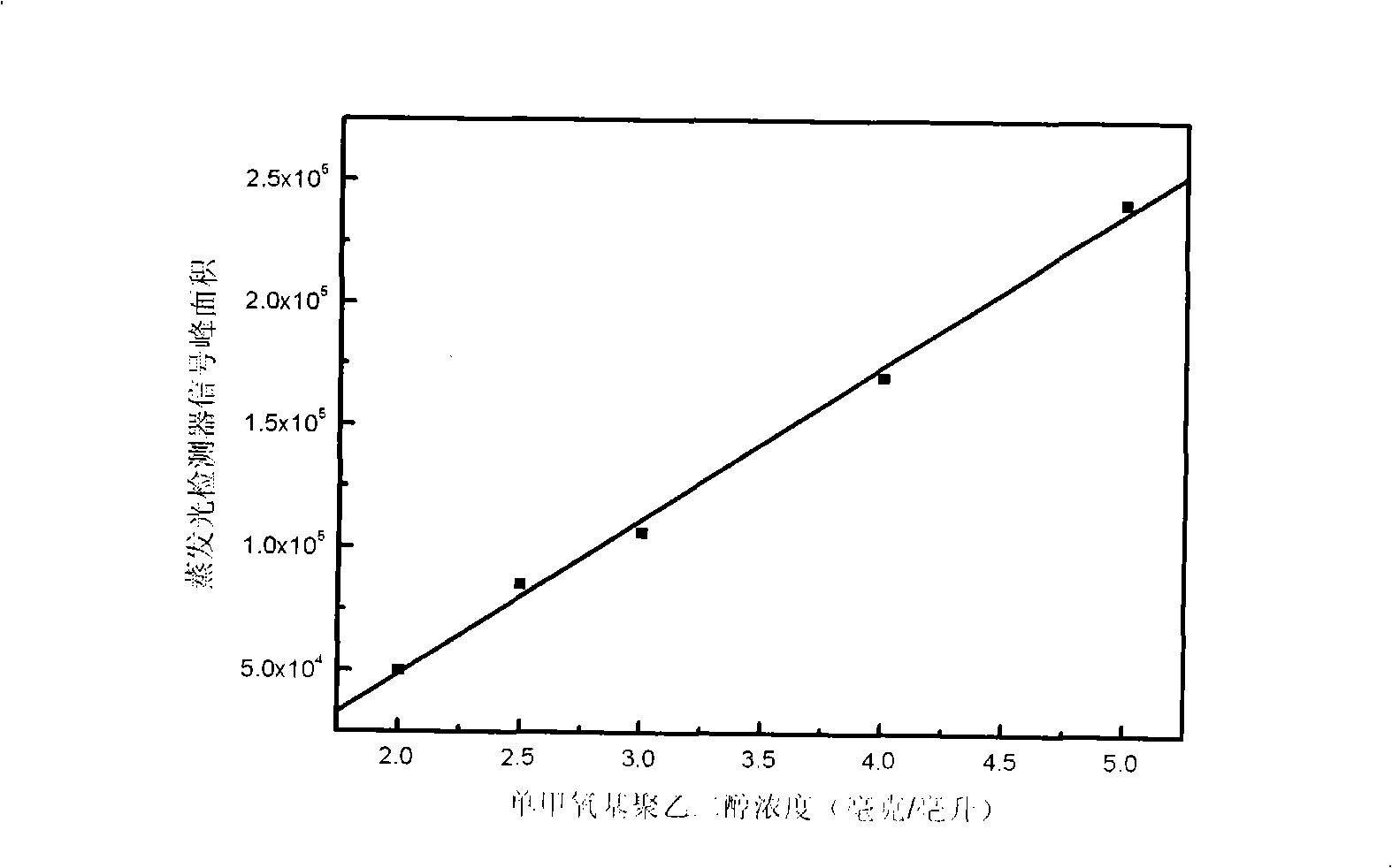

Embodiment 3

[0061] The invention is used to detect the content of free polyethylene glycol in the reaction mixture.

[0062] The standard sample is monomethoxypolyethylene glycol purchased from NEKTAR Company, with a molecular weight of 20,000 Daltons. The sample to be analyzed was the same as the reaction mixture prepared in Example 1, except that the molar ratio of polyethylene glycol succinimide propionic acid / protein was 10:1, and the concentration of polyethylene glycol was 12 mg / ml. All samples are filtered through a 0.45 μm filter membrane, and the concentration of free polyethylene glycol in the sample to be analyzed is calculated (the molar amount of polyethylene glycol added is divided by the volume of the reaction solution), and the concentration of polyethylene glycol diluted with ultrapure water is lower than 5 mg / ml. Similarly, prepare monomethoxypolyethylene glycol standard solution with serial dilutions of 5236, analyze according to the following chromatographic condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com