Preparation method of carbon doped nano titanium dioxide thin film with visible light activity and use thereof

A nano-titanium dioxide and visible light technology, which is applied in nanostructure manufacturing, chemical instruments and methods, nanotechnology, etc., can solve the problems of expensive equipment, high energy consumption of sputtering coating, and difficult control of the method, and achieve the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

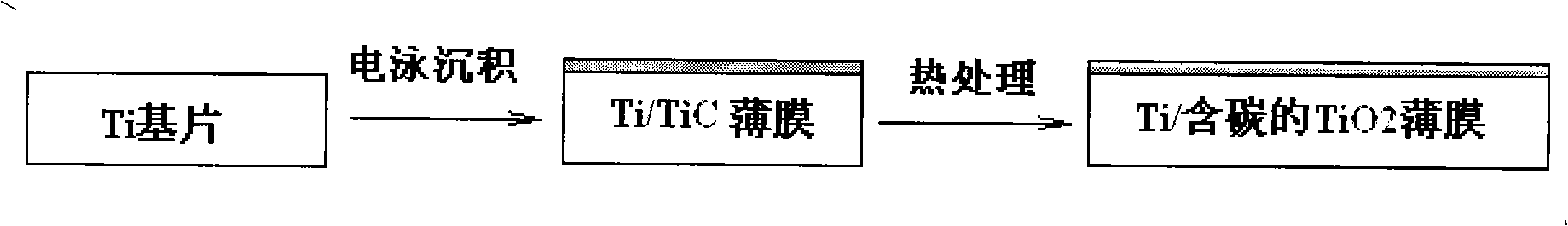

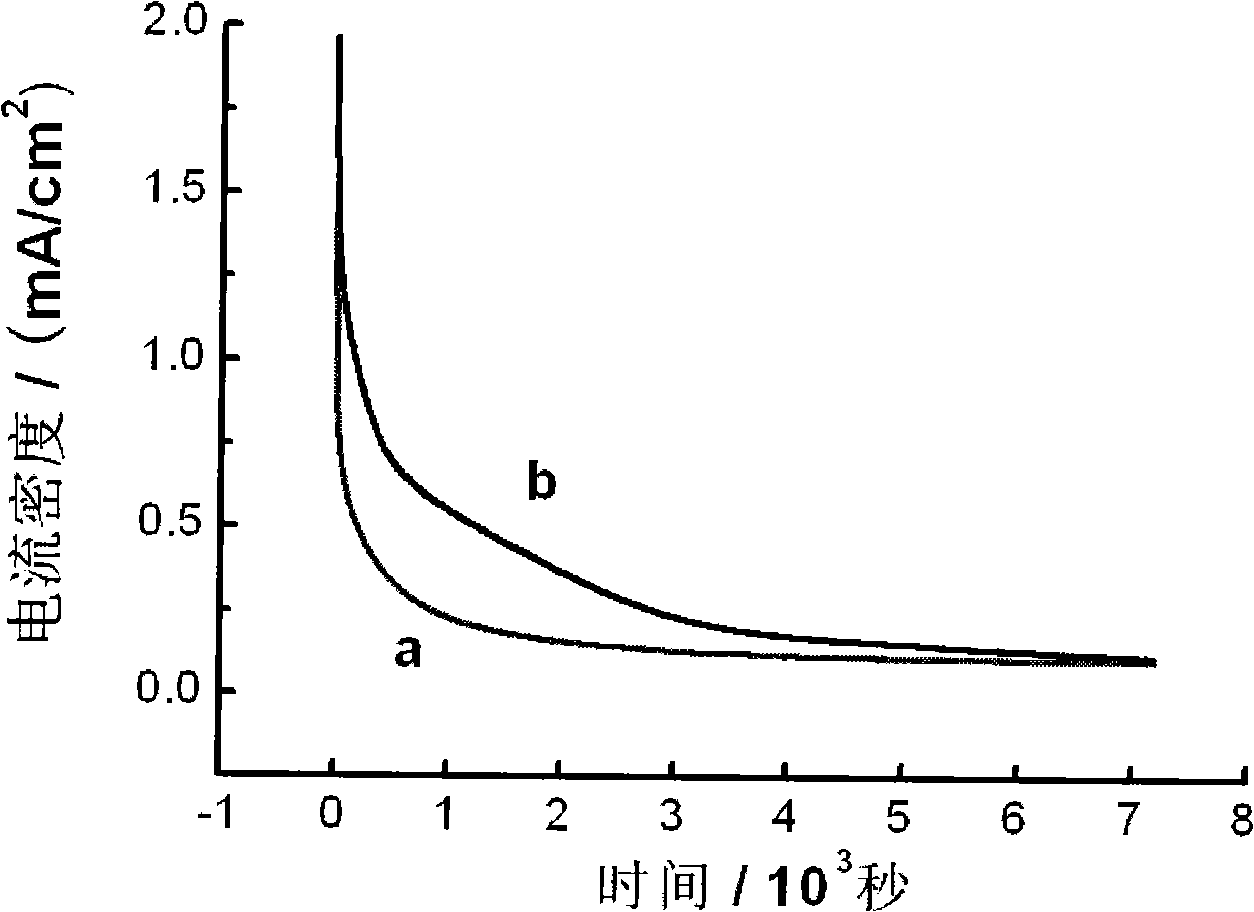

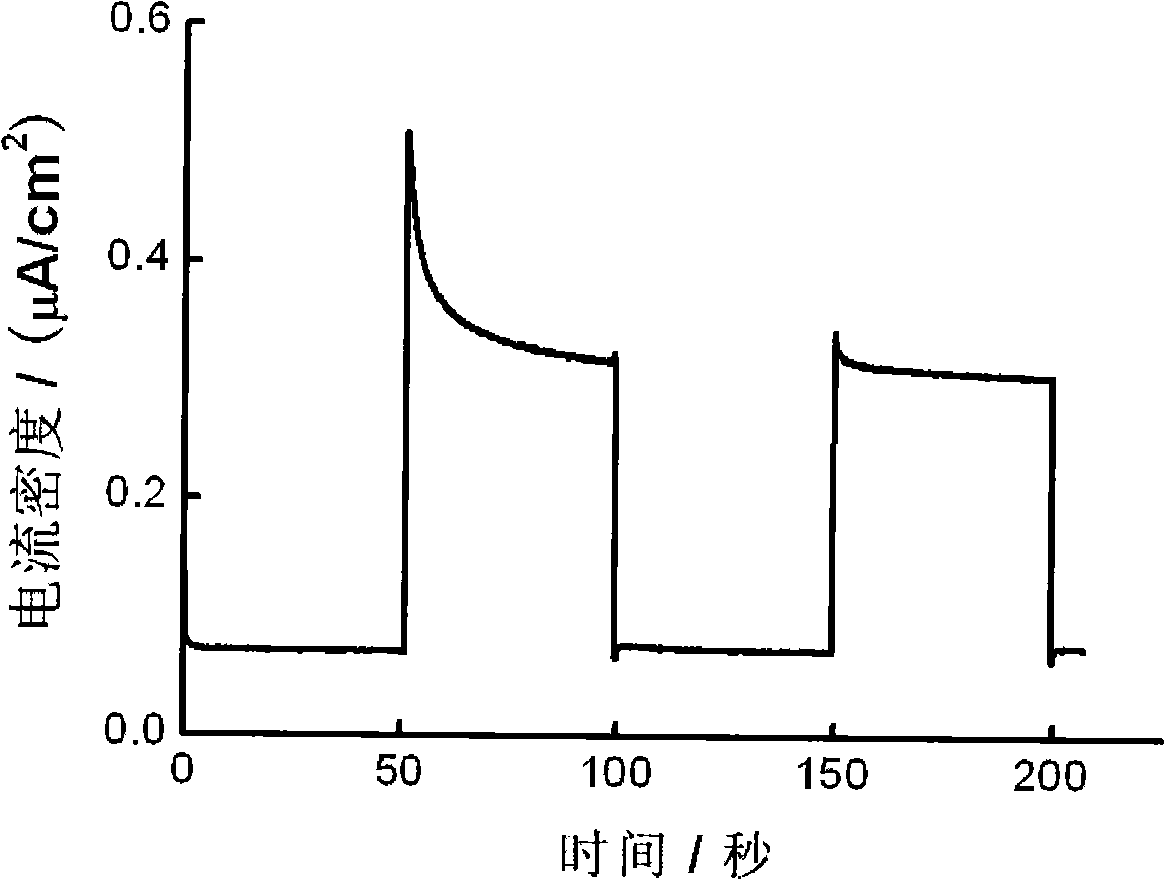

[0032] Prepare a TiC thin film on the surface of the Ti sheet by electrophoretic deposition at room temperature, fix the cleaned Ti sheet in the electrolytic cell, adjust the potential of the potentiostat to 10.0V, and use a titanium carbide suspension containing 10g / L as the electrophoretic deposition solution. Electrophoretic deposition for 2 hours, the current time change curve of the electrophoretic deposition process is as follows figure 2 Shown in the curve a. The obtained TiC film was heat-treated at 350 °C for 2 hours in an air atmosphere, at which time the TiC film transformed into carbon-containing TiO 2 film. image 3 Shows the carbon-containing TiO obtained by electrophoretic deposition of TiC film in this example after heat treatment 2 The photocurrent of the film, it can be seen that the stable short-circuit photocurrent under visible light is 0.23μA / cm 2 .

Embodiment 2

[0034] Prepare a TiC thin film on the Ti surface by electrophoretic deposition method at room temperature, fix the cleaned Ti sheet in the electrolytic cell, use a metal Pt sheet as the counter electrode, adjust the DC stabilized power supply voltage to 30V, and the distance between the electrodes to 1cm, electrophoretic deposition The solution is titanium carbide suspension containing 40g / L, electrophoretic deposition for 8 hours to obtain a TiC film, and the obtained TiC film is heat-treated at 450°C for 2 hours in an air atmosphere, and the TiC film is transformed into carbon-containing TiO 2 film. The XRD pattern of the obtained TiC thin film is as follows Figure 4 Shown in the b curve. The diffraction peak of titanium carbide can be clearly seen from the figure, indicating that titanium carbide has been successfully deposited on the surface of the substrate; at the same time Figure 4 The curve in middle c shows the XRD spectrum of titanium carbide powder after heat tr...

Embodiment 3

[0036] Prepare a TiC thin film on the surface of the Ti sheet by electrophoretic deposition at room temperature, fix the cleaned Ti sheet in the electrolytic cell, adjust the voltage to 13.5V, and use a titanium carbide suspension containing 10g / L as the electrophoretic deposition solution for 2 hours of electrophoretic deposition , the current-time variation curve of the electrophoretic deposition process is as follows figure 2 Shown in the b curve. The obtained TiC film was heat-treated at 350 °C for 2 hours in an air atmosphere, at which time TiC transformed into carbon-containing TiO 2 film. Figure 5 Shows the carbon-containing TiO obtained by electrophoretic deposition of TiC film in this example after heat treatment 2 The photocurrent of the film, it can be seen that the photocurrent under visible light is 0.68μA / cm 2 . Figure 6 Shown is the carbon-containing TiO prepared in this example 2 Photocurrent-potential curves of the film in different states, it can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com