Metal oxide lithium ionic cell positive pole material and preparation thereof

A lithium-ion battery and cathode material technology, applied in the field of lithium-ion battery cathode materials and its preparation, can solve the problems of limited development space, low discharge capacity, capacity fading, etc., and achieve the effect of controllable operation and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of metal oxide lithium ion battery cathode material of the present invention comprises the following steps:

[0022]1. Synthesis of precursor matrix, respectively prepare lithium hydroxide or sodium hydroxide alkali solution with a concentration of 0.5-8 mol / L, Ni, Co, Mn, Al, Ti, Cr, Mg, V with a concentration of 0.5-8 mol / L , Zn and Zr chlorate, sulfate, phosphate or nitrate solution, in the prepared Ni salt solution, Co salt solution, and Mn, Al, Ti, Cr, Mg, V, Zn and Zr salt solution Among the four or five types, add additives respectively according to the mass ratio of the prepared solution at 0-2%, and at the same time, add them into the reaction kettle at the same flow rate, the flow rate is 10-100L / h, and stir continuously to form a uniform precipitation, and at the same time Control the dropping speed of the alkaline solution to adjust the pH value of the solution between 8 and 11.5. The additive is one or more of ammonia water, ethylene...

Embodiment 1

[0029] Example 1, first prepare a sodium hydroxide alkaline solution with a concentration of 2mol / L, prepare a 1mol / L nickel nitrate, cobalt, manganese, and aluminum salt solution with a metal element molar ratio of 4:3:2:1, and prepare a concentration of A mixed solution of ammonia water and ethylene glycol with a mass ratio of 2% of the entire solution, the prepared solutions are simultaneously added to the reaction kettle at a flow rate of 60L / h, and continuously stirred to form a uniform precipitate. Acceleration to adjust the pH of the solution at 10.8.

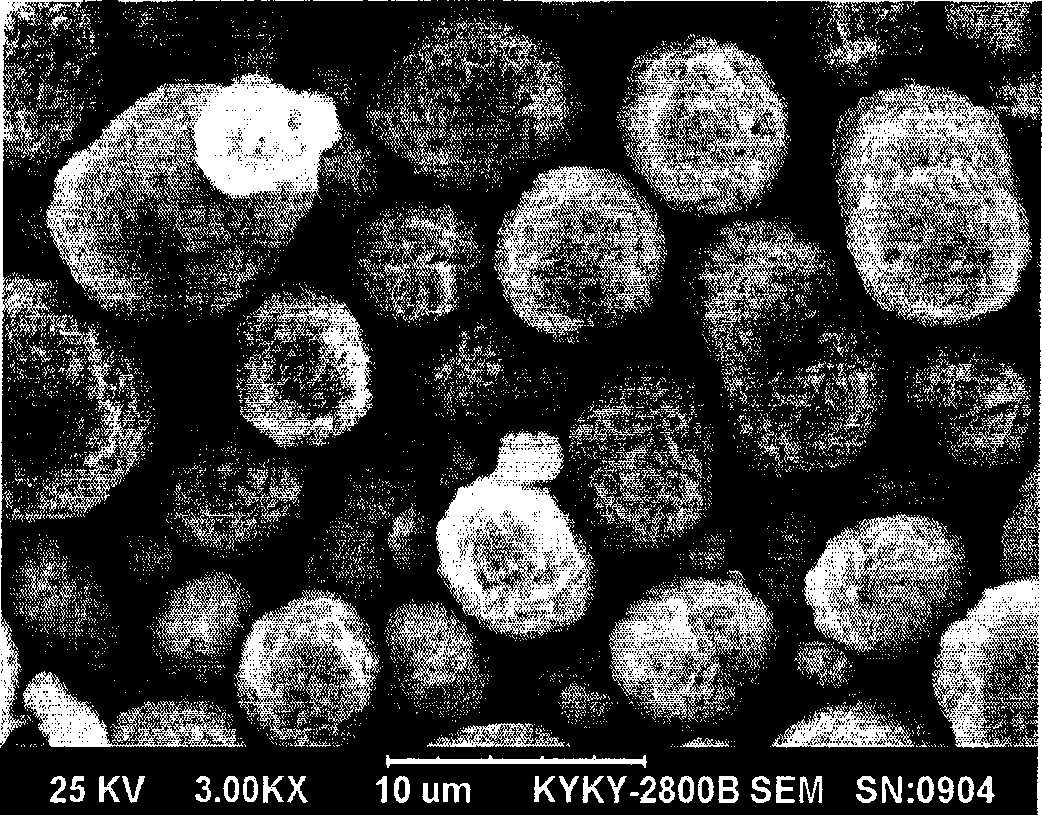

[0030] Filter the precipitated powder in a vacuum filter, measure the pH value of the filtrate to 5, and titrate the filtrate with barium nitrate. When there is no obvious precipitation, the filtration ends; then put the washed precipitate in a vacuum drying oven In the process, the powder was dried at 80°C for 12 hours, and the morphology of the material was as follows figure 1 As shown, the material is a powder with a...

Embodiment 2

[0033] Embodiment 2, first prepare the lithium hydroxide alkali solution of 0.5mol / L concentration, the preparation 0.5mol / L molar ratio is the nickel nitrate, cobalt, manganese, magnesium salt solution of 4:3:2:1, and preparation concentration is simultaneously A mixed solution of ammonia water and ethylenediamine with a mass of 0.5% of the entire solution is added to the reaction kettle at the same time at a flow rate of 10L / h, and continuous stirring is carried out to form a uniform precipitate. Adjust the pH of the solution to 8.

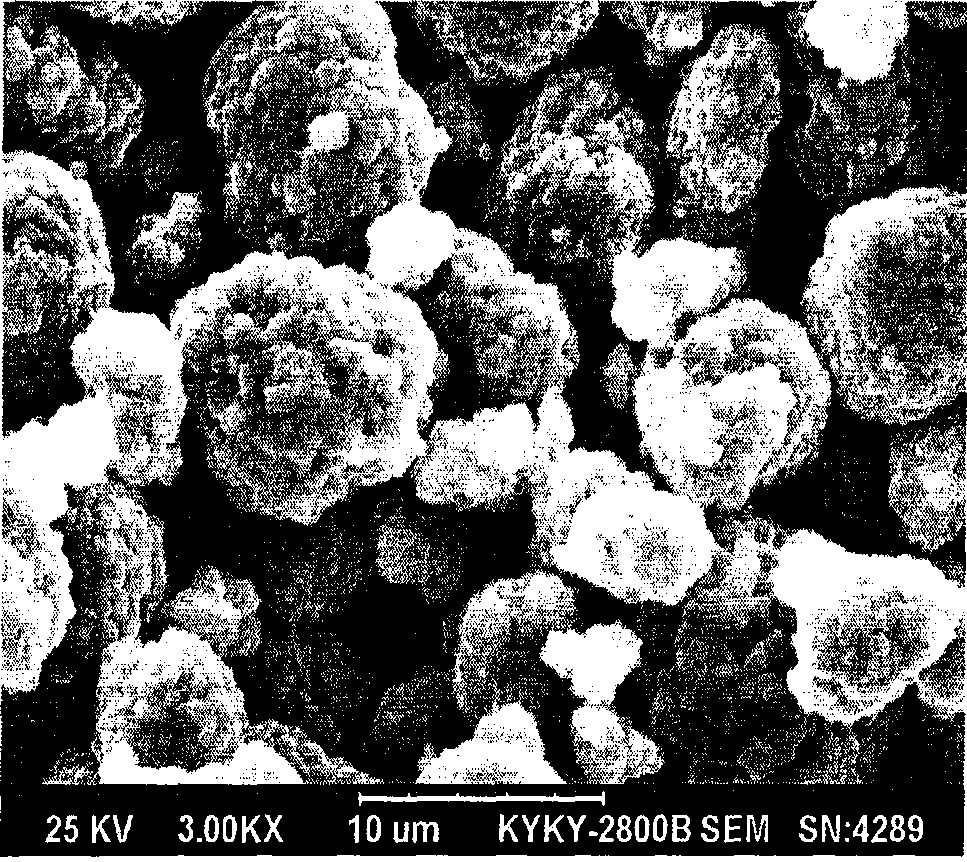

[0034] Filter and wash the precipitated powder in a vacuum filter, measure the pH value of the filtrate to be around 5, and titrate the filtrate with barium nitrate. When there is no obvious precipitation, the filtration ends; Dry the powder at 80°C for 12 hours in a vacuum oven. Mix the dried powder with lithium hydroxide in a molar ratio of 1:1.03 in a spray granulation dryer and dry at 100°C.

[0035] Put the mixed powder into a flat-bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com