Hydrocarbon oil desulphurization adsorbing agent and use method thereof

An adsorbent and hydrocarbon oil technology, which is applied in the fields of refined hydrocarbon oil and petroleum industry, can solve the problems of low yield of hydrocarbon oil, and achieve the effects of high yield of hydrocarbon oil, large adsorption and desulfurization capacity, and uniform pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

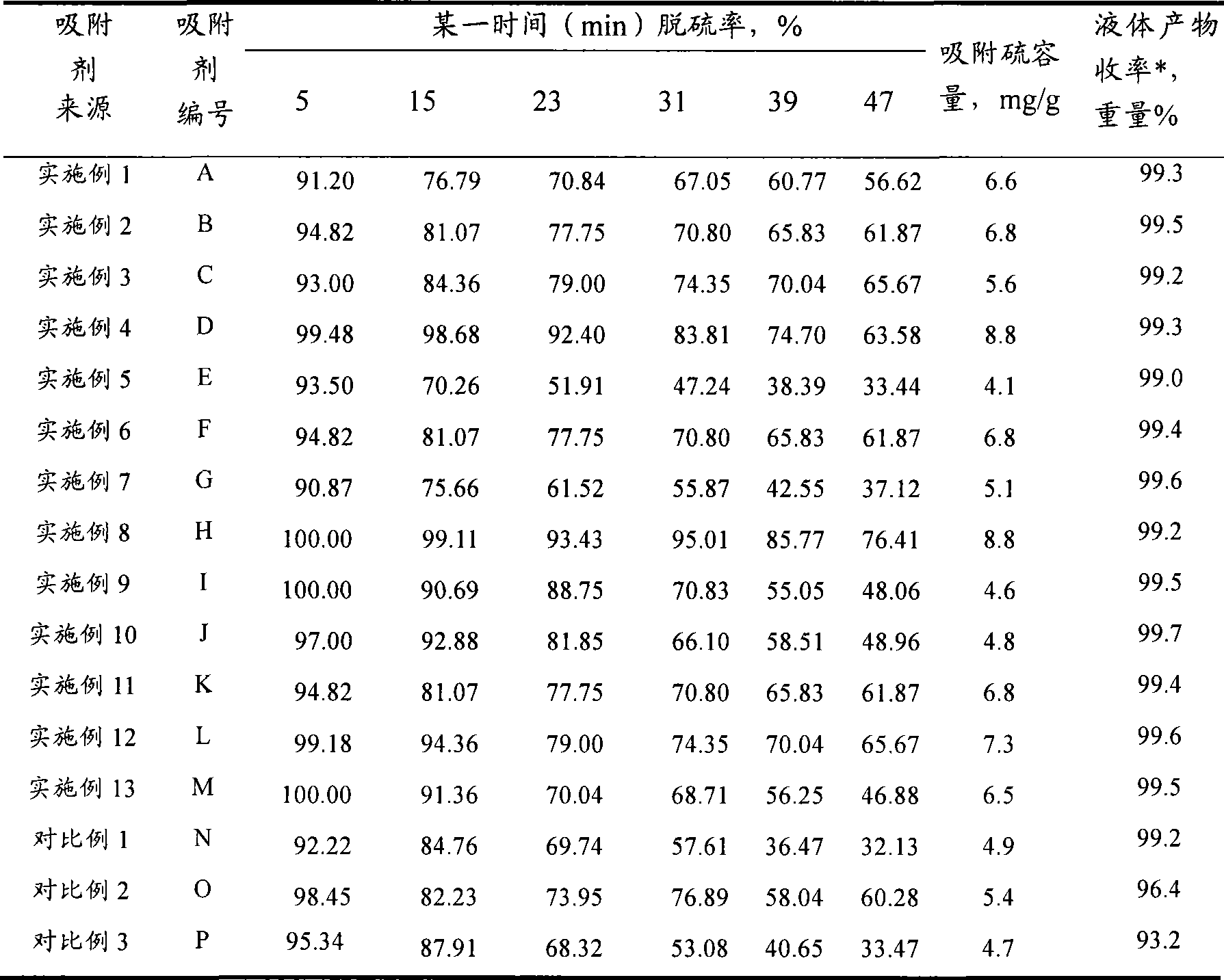

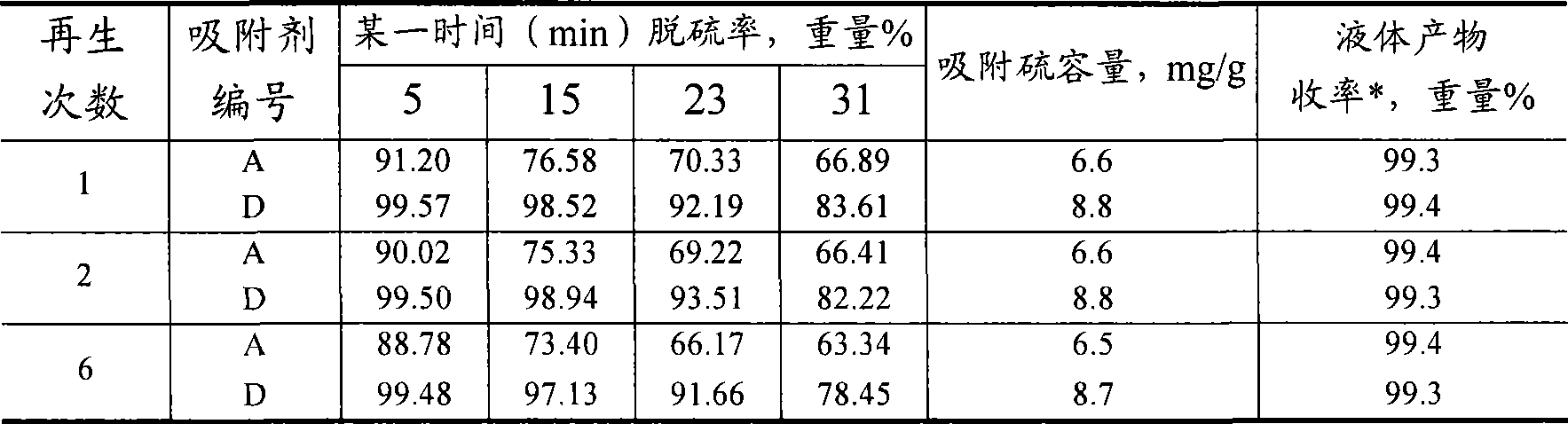

Examples

example 1

[0028] 700 grams of ZSM-5 molecular sieves with an average particle size less than 5 μm (the average particle size of the molecular sieves of other embodiments are the same) (dry basis, silicon-aluminum atomic molar ratio is 100, specific surface area 550m 2 / g) was added to 1500 milliliters of aqueous solution containing 583 grams of zinc nitrate, and under stirring, ammonia water was added to a pH value of 7.5 ± 0.5 to obtain a colloid, which was left to age at room temperature for 3 hours and suction filtered, and washed with deionized water. The filter cake was dried at 150° C. for 4 hours, then roasted at 640° C. in air for 2 hours, then impregnated with 1000 ml of aqueous solution containing 122 grams of cobalt nitrate for 4 hours, then dried at 150° C. for 4 hours, and roasted at 640° C. in air for 2 hours. Adsorbent A is obtained.

[0029] The composition of the adsorbent A was 70% by weight of molecular sieve, 25% by weight of zinc oxide, and 5% by weight of cobalt ox...

example 2

[0031] ZSM-5 molecular sieve (dry basis, silicon aluminum atomic molar ratio is 300, specific surface area 430m 2 / g) mixed with pseudo-boehmite and kaolin for beating, and then spray-dried to make microspheres, wherein the content of alumina is 20% by weight, the content of kaolin is 30% by weight, and the content of molecular sieve is 50% by weight.

[0032] Take 500 grams of the above-mentioned microspheres and add them to 1500 milliliters of an aqueous solution containing 583 grams of zinc nitrate, add ammonia water under stirring until the pH value is 7.5 ± 0.5 to obtain a colloid, leave it to age at room temperature for 3 hours, then suction filter it, and use 5000 ml of deionized water Wash to remove nitrate ions, dry the resulting filter cake at 150°C for 4 hours, then roast in the air at 640°C for 2 hours, then impregnate three times with 3000 ml of aqueous solution containing 610 g of cobalt nitrate, each solution consumption is 1000 ml, Immerse for 4 hours, and afte...

example 3

[0035] 700 grams of ZSM-5 molecular sieves (same as Example 1) with an average particle size of less than 5 μm were added to 1500 milliliters of an aqueous solution containing 698 grams of zinc nitrate, and ammonia was added under stirring until the pH value was 7.5 ± 0.5 to obtain a colloid, which was left to age at room temperature Suction filtration after 3 hours, after washing with deionized water, the resulting filter cake was dried at 150° C. for 4 hours, and then roasted in air at 640° C. for 2 hours to obtain adsorbent C, which was composed of 70% by weight of molecular sieve and 30% by weight of zinc oxide. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com