Method of purifying water and apparatus therefor

A water purification device and water purification technology are applied to chemical instruments and methods, descaling and water softening, water/sewage treatment, etc., which can solve the problems of increased cooling water costs, air pollution, and large costs, and achieve life extension, The effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] The water of the cooling tower of 120 refrigerated tons was extracted from the circulation path, purified by the apparatus of the present invention, and returned to the circulation path after purification.

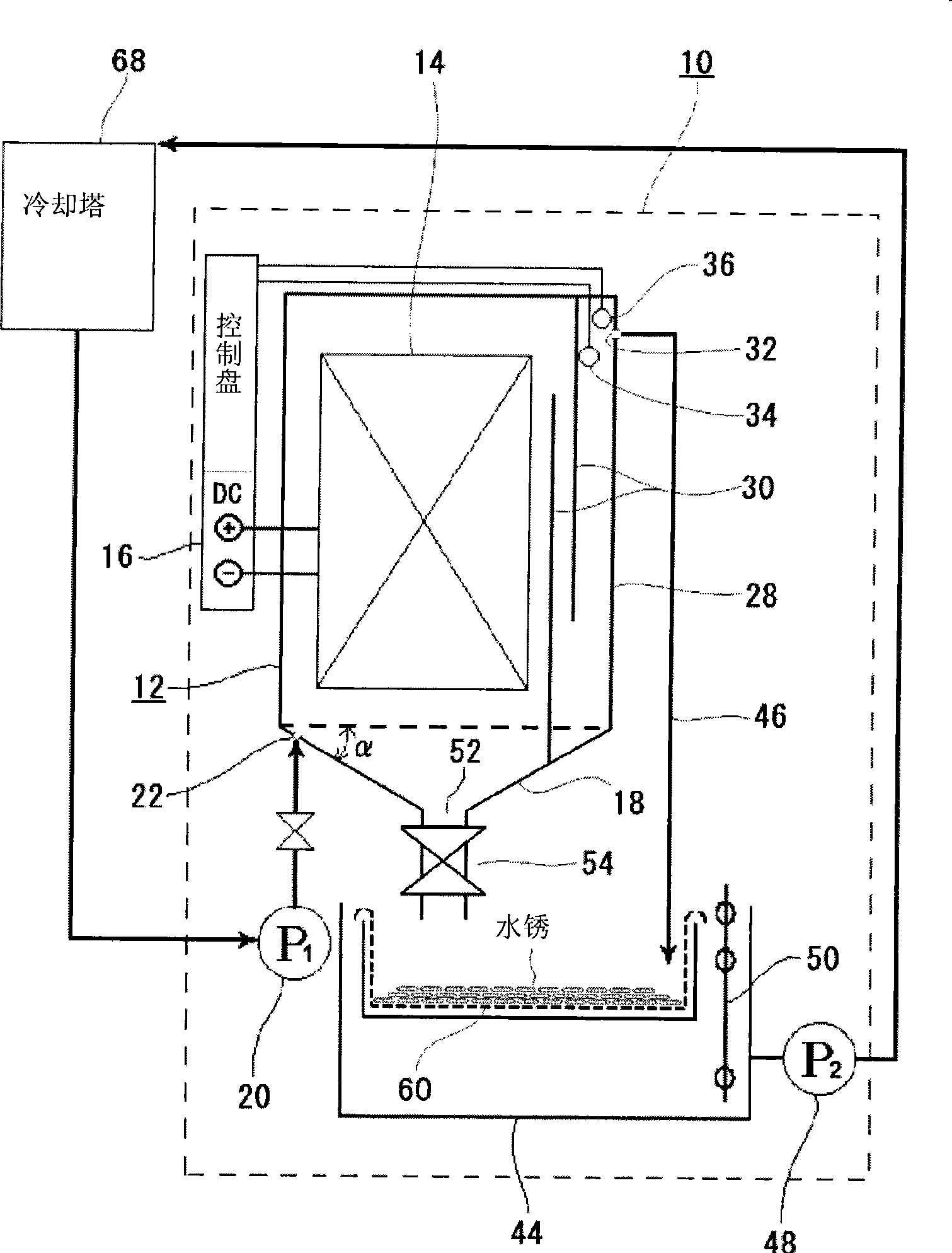

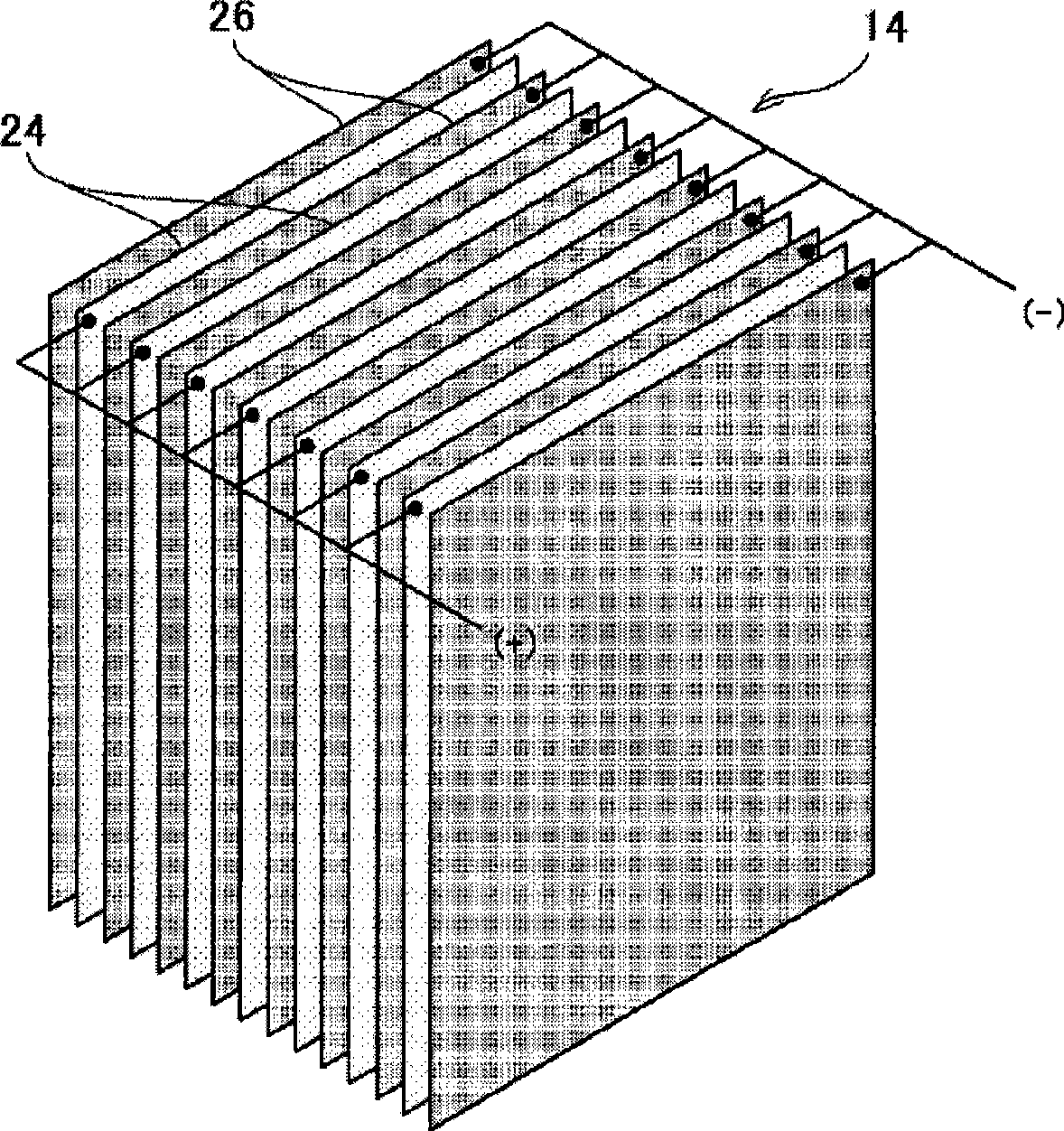

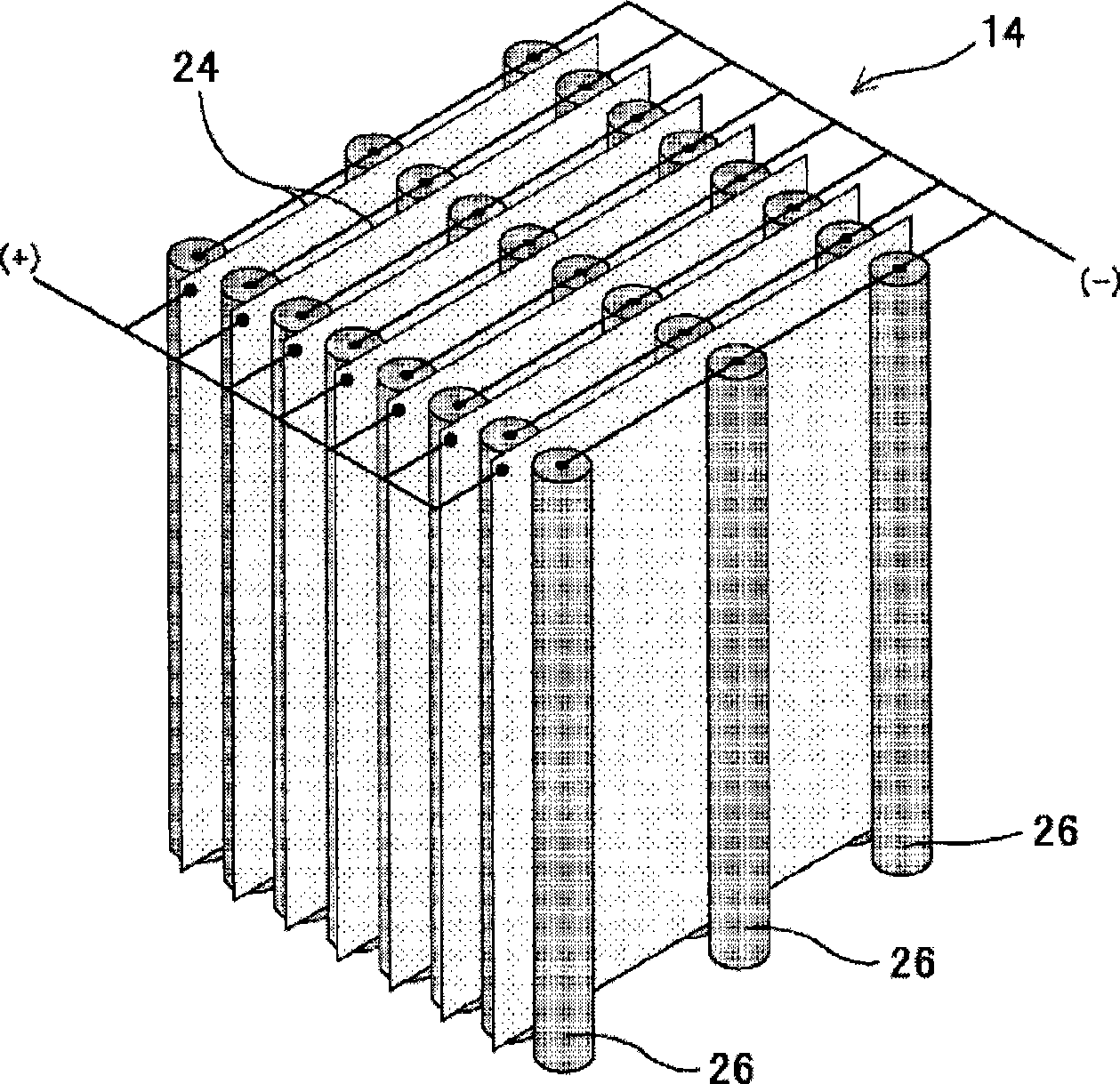

[0124] The electrode assembly 14 of the device of the present invention uses two types of electrode assemblies, A and B. The electrode assembly of pattern A is composed of 36 titanium plates and 36 aluminum plates each with a width of 300mm × a height of 600 mm × a thickness of 1 mm, a total of 72 plates, which are alternately opposed at 12.5 mm intervals (refer to figure 2 ). In addition, the electrode assembly of style B is made of titanium plate with width 300mm x height 600mm x thickness 1mm and 15mm×600mm×3 aluminum round rods are used as a component, and a total of 36 components are formed opposite each other (refer to image 3 ). In addition, the DC power supply device 16 uses a DC stabilization power supply device, and supplies a constant current of 6 A...

Embodiment 2

[0128] The current density flowing in the electrode assembly was changed to three types, 1A / m2, 2A / m2, and 3A / m2, and a table experiment on a scale of about 1 / 35 of Example 1 was carried out, and the cycle treatment was carried out. As a result, the conductivity of water like Figure 12 (a), (b). This experiment shows that the higher the current density, the lower the conductivity of water. However, in the case of either of the electrode assemblies 14 of the styles A and B, the decrease in the conductivity of the water did not show a large difference.

[0129] In addition, the current density flowing in the electrode assembly was set to 0.5A / m2, 1A / m2, 4A / m2, 10A / m2, 20A / m2, and a table-top experiment on a scale of about 1 / 35 of Example 1 was carried out, and the cycle was carried out. processing, the result is Figure 13 As shown in (a), (b), the conductivity of water is reduced. This experiment shows that the greater the current density, the faster the reduction in the e...

Embodiment 3

[0131] Continued operation for one week under the conditions of Example 1 resulted in a little residual scale adhering to the electrode surface, but the adhesion was hardly firm, and the peeled scale was well deposited on the bottom of the electrolytic cell. In addition, in the case of either of the electrode assemblies 14 of the styles A and B, the deposition of the peeled scale did not show a large difference.

[0132] The results of chemical analysis of its components are shown in the upper column of Table 1. The titanium component of the positive electrode is about 40% due to insulation damage, the aluminum component of the negative electrode side that is considered to be corroded by electric corrosion is about 11%, and the remaining complement constitutes scale. ingredients. In addition, in the case of any of the electrode assemblies 14 of the styles A and B, there was almost no difference in the scale components.

[0133] 【Table 1】

[0134]

[0135] In addition, as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com