Sb2O3 doped ZnOw/PZT two-phase piezoelectric composite ceramic and preparation thereof

A piezoelectric composite and ceramic technology, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of high brittleness and short life, achieve low cost, improve piezoelectric performance, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

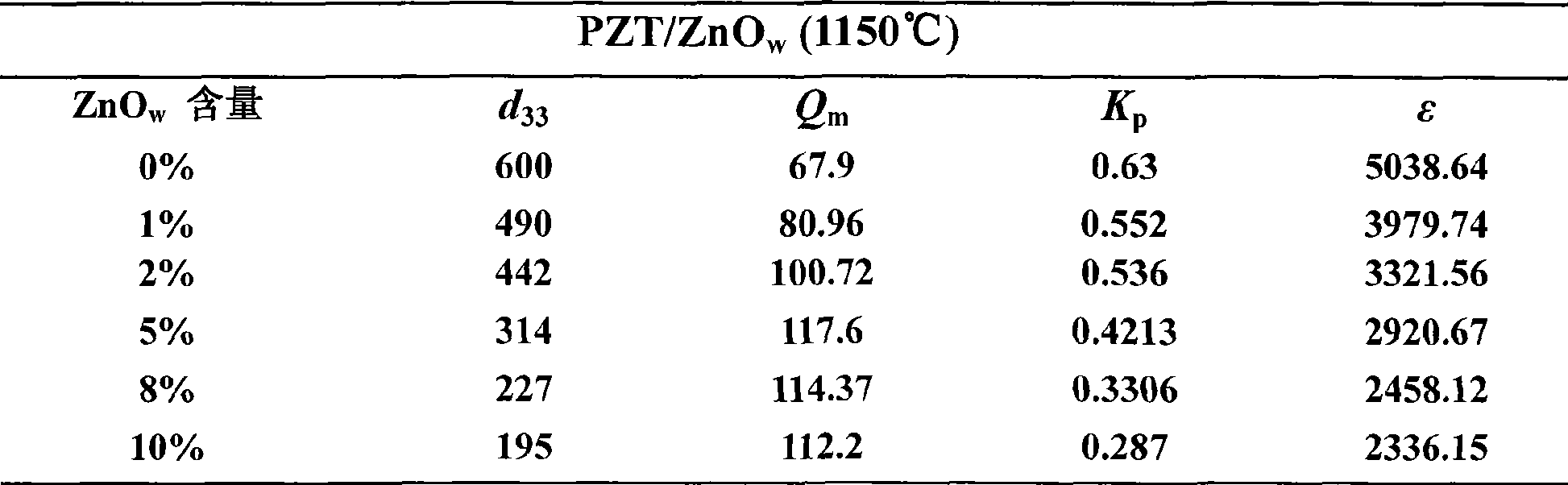

[0020] To prepare with 0.5% Sb 2 o 3 Powder, 1% ZnO whisker dual-phase piezoelectric composite ceramics as an example, the raw material used is Sb 2 o 3 0.5 grams of powder, 1 gram of ZnO whiskers, 98.5 grams of PZT powder, 6 grams of polyvinyl alcohol solution with a concentration of 5 wt%. The specific operation is as follows:

[0021] 1) At room temperature, ZnO nano whiskers, PZT powder, Sb 2 o 3 Mix the powder and alcohol in a ball mill and mill for 3 hours; add the polyvinyl alcohol solution to the powder and mix and mill for 24 hours; dry and stir the obtained mixture in a blast drying oven at 100°C for 10 hours to form a solid, then Grind and pass through a 60-mesh sieve into powder;

[0022] 2) Press the powder in a stainless steel grinding tool (1t / cm 2 ) into green bodies, which can be pressed into green bodies of different sizes and styles required by using different abrasive tools, such as discs and strips. ℃, keep the temperature for 2 hours for debinding...

Embodiment 2

[0024] To prepare with 1% Sb 2 o 3 Powder, 2% ZnO whisker biphasic piezoelectric composite ceramics as an example, the raw material used is Sb 2 o 3 1 gram of powder, 1 gram of ZnO whiskers, 98 grams of PZT powder, 8 grams of polyvinyl alcohol solution with a concentration of 5 wt%. The specific operation is as follows:

[0025] 1) At room temperature, ZnO nano whiskers, PZT powder, Sb 2 o 3 Mix the powder and alcohol in a ball mill, and mill for 5 hours; add polyvinyl alcohol solution to the powder and mix, and mill for 12 hours; dry and stir the obtained mixture in a blast drying oven at 150°C for 5 hours to form a solid, and then Grind and pass through a 60-mesh sieve into powder;

[0026] 2) Press the powder in a stainless steel grinding tool (1t / cm 2 ) into green bodies, which can be pressed into green bodies of different sizes and styles required by using different abrasive tools, such as discs and strips. ℃, keep the temperature for 2 hours for debinding; then r...

Embodiment 3

[0028] To prepare with 2% Sb 2 o 3 Powder, 5% ZnO whiskers biphasic piezoelectric composite ceramics as an example, the raw material used is Sb 2 o 3 2 grams of powder, 1 gram of ZnO whiskers, 97 grams of PZT powder, 8 grams of polyvinyl alcohol solution with a concentration of 4 wt%. The specific operation is as follows:

[0029] 1) At room temperature, ZnO nano whiskers, PZT powder, Sb 2 o 3 Mix the powder and alcohol in a ball mill, and ball mill for 8 hours; add polyvinyl alcohol solution to the powder and mix, and ball mill for 18 hours; dry and stir the obtained mixture in a blast drying oven at 110°C for 6 hours to form a solid, and then Grind and pass through a 60-mesh sieve into powder;

[0030] 2) Press the powder in a stainless steel grinding tool (1t / cm 2 ) into green bodies, which can be pressed into green bodies of different sizes and styles required by using different abrasive tools, such as discs and strips. ℃, hold the temperature for 2 hours for debindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com