Low-melting point PTT copolyester and manufacturing method thereof

A manufacturing method and technology of copolyester, applied in the direction of single-component copolyester rayon, adhesive, etc., can solve the problems of insufficient stability and other problems, and achieve the effect of fast reaction speed, less adhesion and less side reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

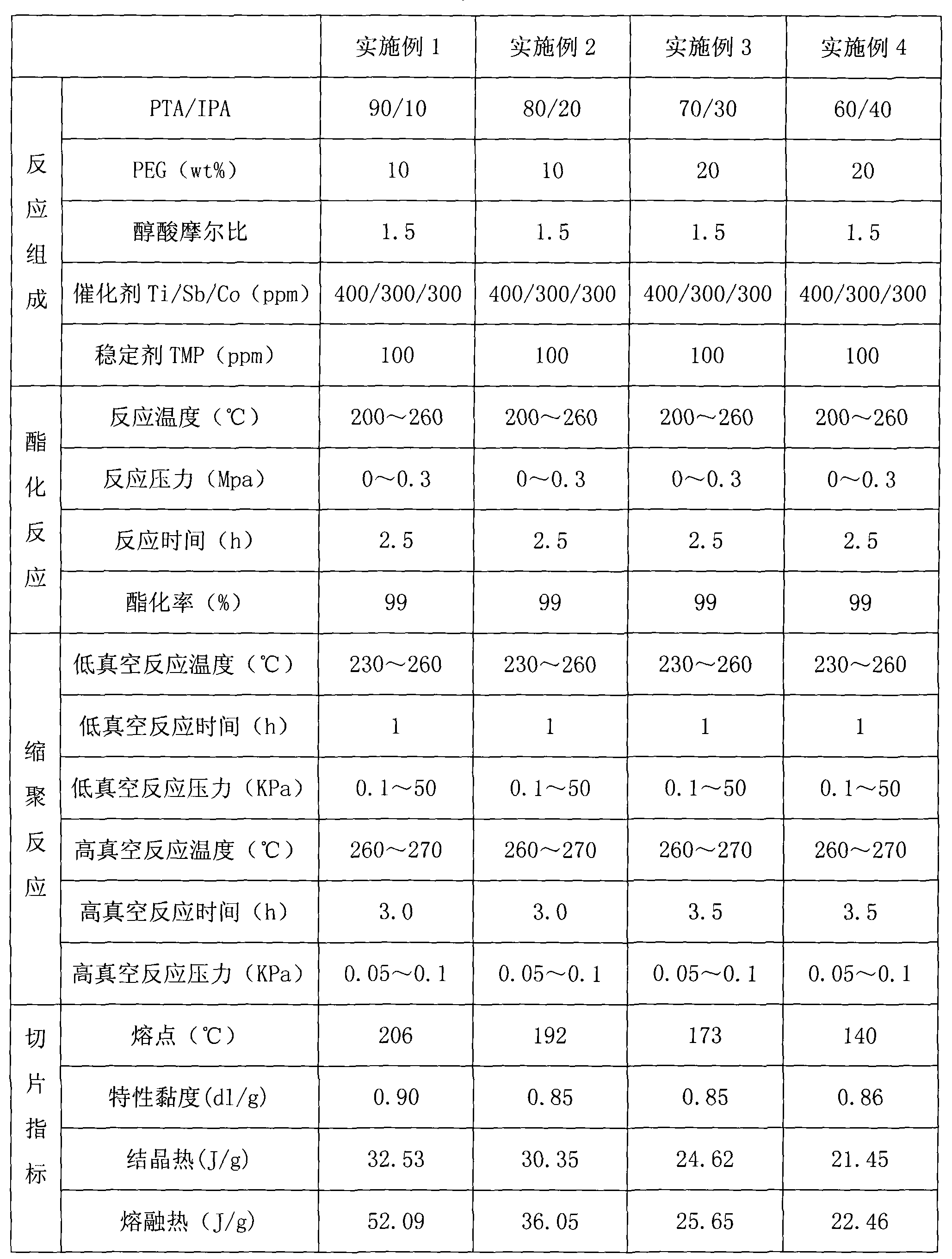

[0024] Low melting point PTT copolyester of the present invention, it forms through esterification reaction and polycondensation reaction with following monomer,

[0025] (a) Terephthalic acid (PTA) and isophthalic acid (IPA)

[0026] (b) 1,3-propanediol (PDO)

[0027] (c) Polyethylene glycol 600~6000 (PEG)

[0028] Among them, in component a, the mass ratio of terephthalic acid to isophthalic acid is between 90-50:10-50; in component c, the weight ratio of polyethylene glycol is 1-20% based on a; a The molar ratio with b is 1:1.2~1.8.

[0029] The intrinsic viscosity of the copolyester described in the present invention is between 0.70-0.90dL / g, and the melting point is between 130-200°C.

[0030] A kind of manufacture method of low melting point PTT copolyester of the present invention, this method comprises two processes of esterification reaction and polycondensation reaction;

[0031] The raw materials for the esterification reaction are: in the acid component, tereph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com