Preparation method of nano-crystal soft magnetic alloy elements

A nanocrystalline soft magnetic and nanocrystalline alloy technology, applied in the field of soft magnetic materials, can solve problems such as being unsuitable for industrial production, single product shape, product performance degradation, etc., and achieve high stability, complex and diverse shapes, and high saturation magnetic induction intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

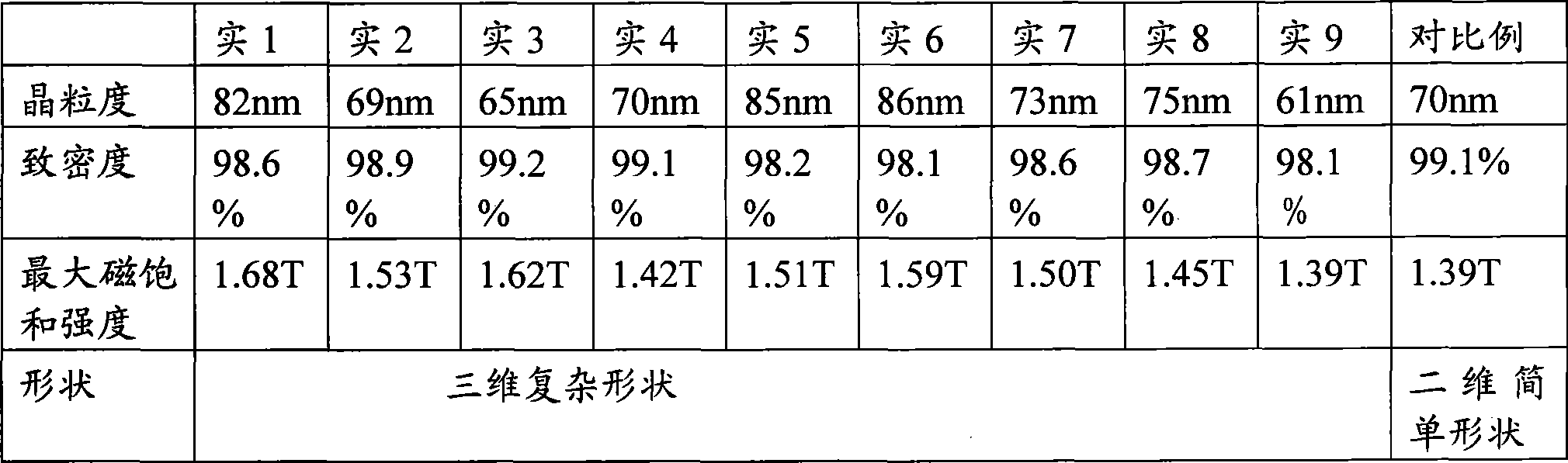

Examples

Embodiment 1

[0029] Preparation of Nanocrystalline Soft Magnetic Alloy Fe 73.5 Si 13.5 B 9 Nb 3 Cu 1 :

[0030] ① Place the powders of each component of the nanocrystalline alloy element in a ball milling tank, and ball mill for 30 hours under an argon atmosphere to obtain a nanocrystalline alloy powder; wherein the rotating speed of the ball milling tank is 300 rpm, the ball-to-material ratio is 7:1, and the grinding medium adopts Wear-resistant steel ball;

[0031] ②Knead the nanocrystalline alloy powder prepared in step ① and the binder polyethylene on a mixer for 1.2 hours, and then granulate on an extruder; after granulation, inject at an injection temperature of 120°C and an injection pressure of 55MPa Forming to obtain the desired shape of the soft magnetic alloy green body. Wherein the volume ratio of the nanocrystalline alloy powder and the binder is 70:30;

[0032] ③Immerse the soft magnetic alloy green body prepared in step ② in the degreasing solvent trichlorethylene at ...

Embodiment 2

[0034] Preparation of Nanocrystalline Soft Magnetic Alloy Fe 73.5 Si 13.5 B 9 Nb 3 Cu 1 :

[0035] ① Place the powders of each component of the nanocrystalline alloy element in a ball milling tank, and ball mill for 40 hours under an argon atmosphere to obtain a nanocrystalline alloy powder; wherein the rotating speed of the ball milling tank is 300 rpm, the ball-to-material ratio is 7:1, and the grinding medium adopts Wear-resistant steel ball;

[0036] ②Knead the nanocrystalline alloy powder prepared in step ① and the binder paraffin on the mixer for 1.5h, and then granulate on the extruder; after granulation, injection molding is performed at an injection temperature of 120°C and an injection pressure of 60MPa , to obtain the desired shape of the soft magnetic alloy green body. Wherein the volume ratio of the nanocrystalline alloy powder and the binder is 70:30;

[0037] ③Immerse the soft magnetic alloy green body prepared in step ② in the degreasing solvent acetone ...

Embodiment 3

[0039] Preparation of Nanocrystalline Soft Magnetic Alloy Fe 73.5 Si 13.5 B 9 Nb 3 Cu 1 :

[0040] ① Place the powders of each component of the nanocrystalline alloy element in a ball milling tank, and ball mill for 50 hours under an inert protective atmosphere to obtain a nanocrystalline alloy powder; wherein the rotating speed of the ball milling tank is 300 rpm, the ball-to-material ratio is 7:1, and the grinding medium adopts Wear-resistant steel ball;

[0041] ②Knead the nanocrystalline alloy powder prepared in step ① and the binder stearic acid on the mixer for 1.5 hours, and then granulate on the extruder; after granulation, the injection temperature is 130°C and the injection pressure is 60MPa. Injection molding to obtain the desired shape of the soft magnetic alloy green body. Wherein the volume ratio of the nanocrystalline alloy powder and the binder is 75:25;

[0042]③Immerse the soft magnetic alloy green body prepared in step ② in the degreasing solvent tric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com