Accelerator-driven subcritical transmutation reactor core adopting dispersion metal fuel

An accelerator-driven, metal fuel technology, applied in subcritical reactors, fuel elements, nuclear reactors, etc., can solve the problems of high transmutation rate, low MA transmutation rate, and high fuel manufacturing costs, and achieve low proton beam current intensity and high reactor efficiency. The effect of simple core structure and high utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The structure of the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

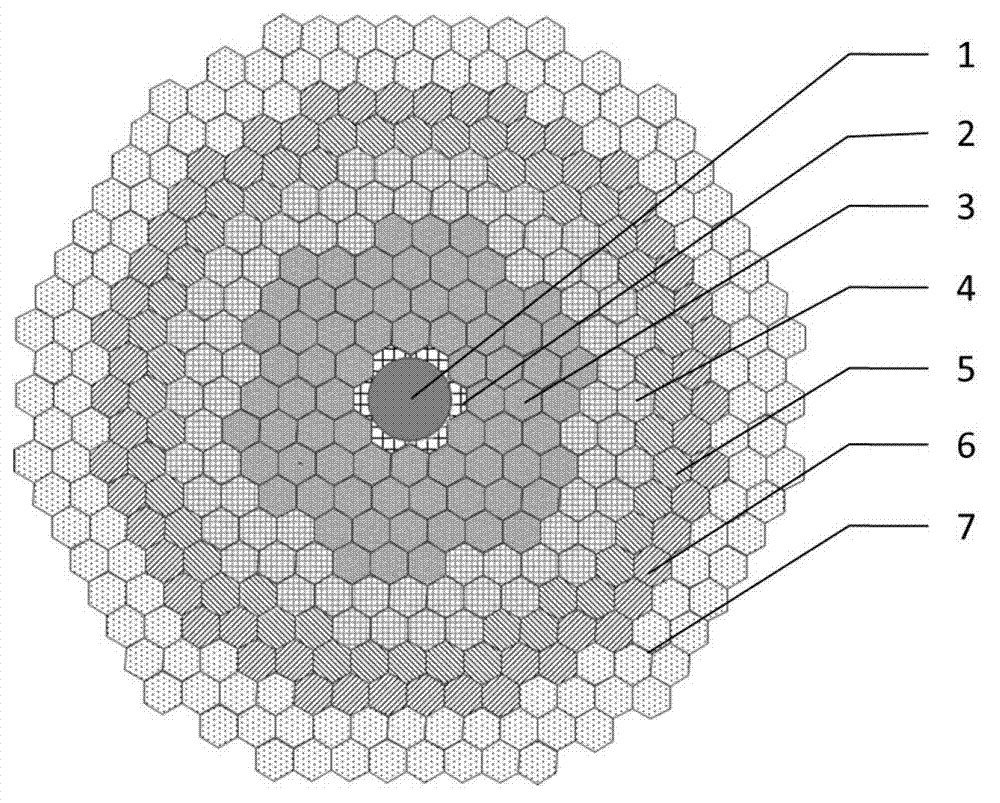

[0034] Such as figure 1 As shown, an accelerator-driven subcritical transmutation core of the present invention adopts dispersoid metal fuel. Taking the fuel zone of two zones as an example, it includes an outer neutron source zone 1, a buffer zone 2, and a fuel zone from the center of the core to the outside. Inner zone 3, fuel outer zone 4, LBE reflector zone 5, stainless steel reflector zone 6 and shield zone 7, the total core height is 290cm, and the diameter is 359.4cm, of which the height of the active zone is 110cm, and the diameter is 226.8cm.

[0035] Such as figure 2 As shown, the axial lower ends of the fuel inner zone 3 and the fuel outer zone 4 are 50 cm high stainless steel reflective layer 6, and axially upwards are 110 cm high air chamber 8 and 20 cm high stainless steel reflective layer 6. The outer neutron source area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com