Separation and purification method for Dunaliella salina polysaccharide

A technique for the separation and purification of polysaccharides from Dunaliella salina, applied in the biotechnology of salina salina and its products, and in the field of chromatographic separation, can solve the problems of lack of systematic and in-depth research on the separation and purification of polysaccharides, and the lack of research and utilization. The method is simple and practical, and is conducive to popularization , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take 200g of Dunaliella salina powder, heat and extract with 2000mL of pH 8.5 NaOH alkaline aqueous solution in a water bath at 90°C for 3.0 hours, extract twice, and combine to obtain the extract; adjust the pH of the extract to 4.0 with 2mol / L HCl, and centrifuge (4000r / min) 20min, after concentrating the supernatant, use 3.8 times of 95% ethanol alcohol precipitation, low temperature (4 ℃) for 8 hours, centrifugal, suction filtration, take the filter cake and vacuum dry to obtain the crude extract; The free protein was removed by Sevag method, followed by dialysis and concentration to obtain the crude polysaccharide concentrate which was preliminarily purified. After freeze-drying the crude polysaccharide concentrate, the polysaccharide content was determined by the phenol-sulfuric acid method to be 75.5%, and the yield was 9.0%.

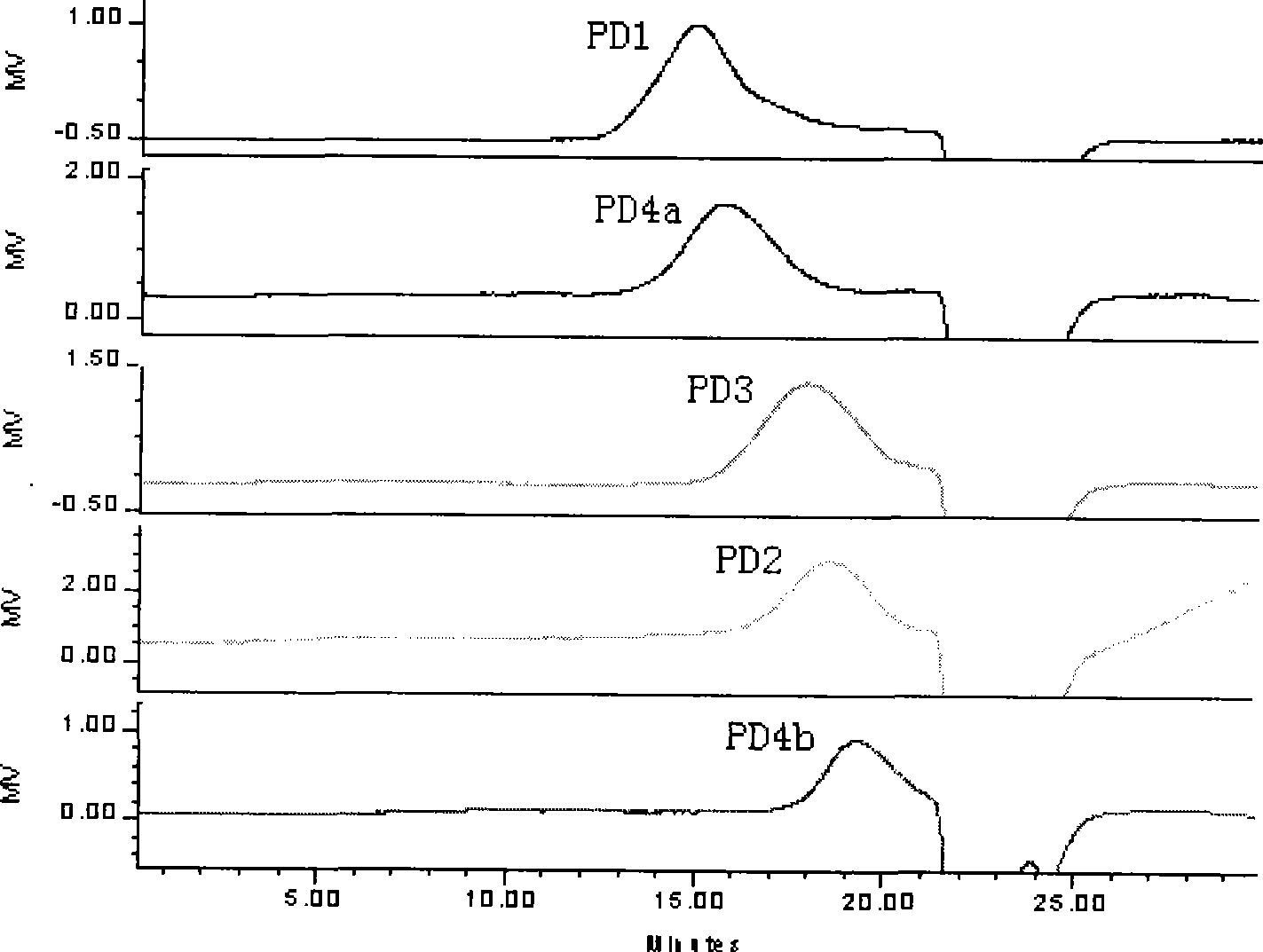

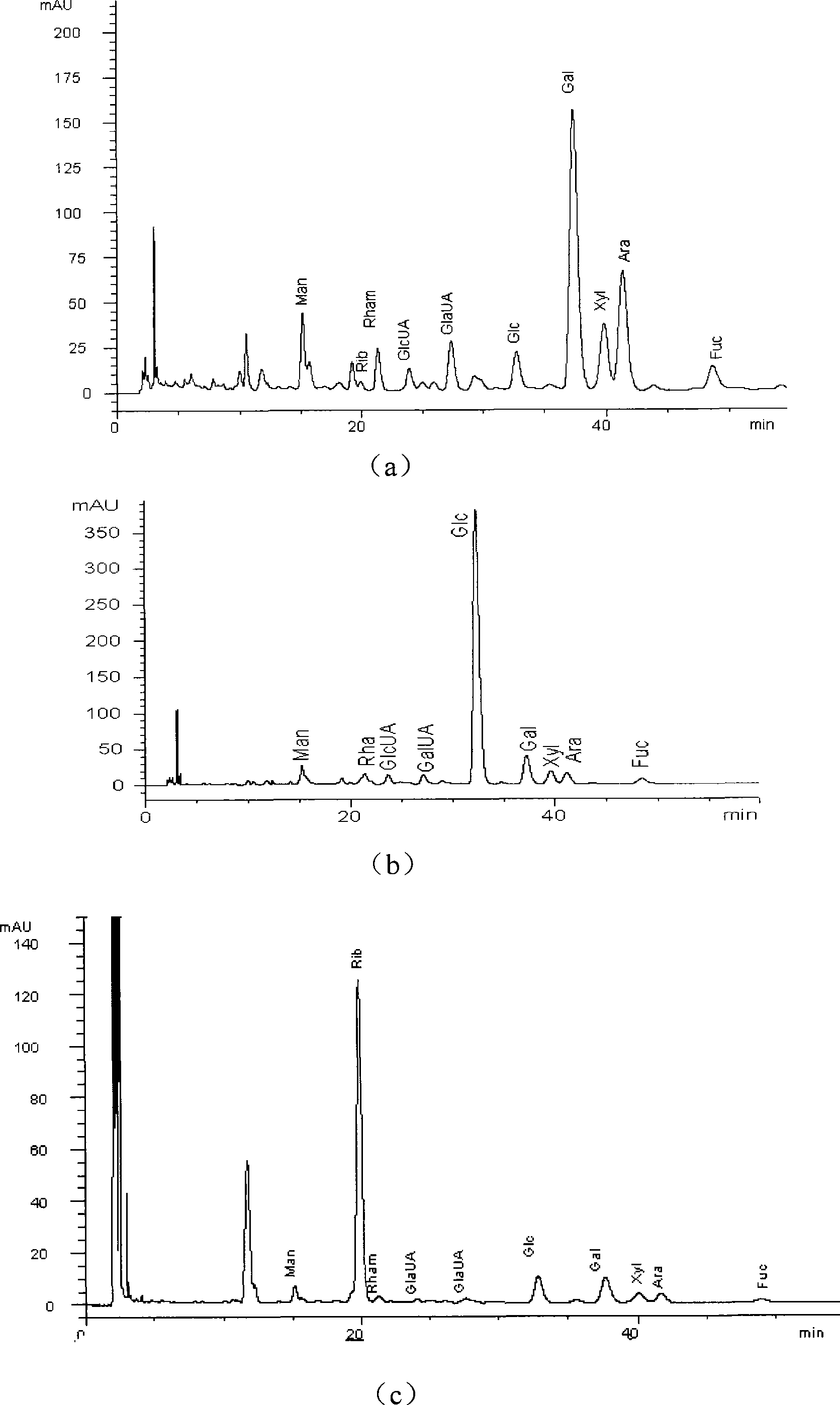

[0018] Load 50 mL of the crude polysaccharide concentrate that was initially purified on a DEAE-Sepharose Fast folw column (3.5 cm × 30 c...

Embodiment 2

[0021] Take 500g of Dunaliella salina powder, heat and extract with 7500mL of pH9.0 alkaline aqueous solution at 80°C in a water bath for 4 hours, extract twice, and combine to obtain the extract; adjust the pH of the extract to 3.5 with 2mol / L HCl, and centrifuge (4000r / min) 20min, the obtained supernatant was concentrated, and the polysaccharide was precipitated with 3.8 times the volume of 95% ethanol, left standing overnight at low temperature (4°C), centrifuged, suction filtered, and the filter cake was vacuum-dried to obtain the crude extract; further use Sevag The free protein was removed by the method, and the crude polysaccharide concentrate was obtained by dialysis and concentration. After freeze-drying the crude polysaccharide concentrate, the polysaccharide content was determined by the phenol-sulfuric acid method to be 78.2%, and the yield was 8.5%.

[0022] Load 50 mL of the initially purified crude polysaccharide aqueous solution (10 mg / mL) on a DEAE-Sepharose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com